-

Email Us

- Top Reports

Exploring the Role of Activated Carbon Manufacturers: Trends, Insights, and Future Opportunities Introduction

Posted On 21 October, 2024

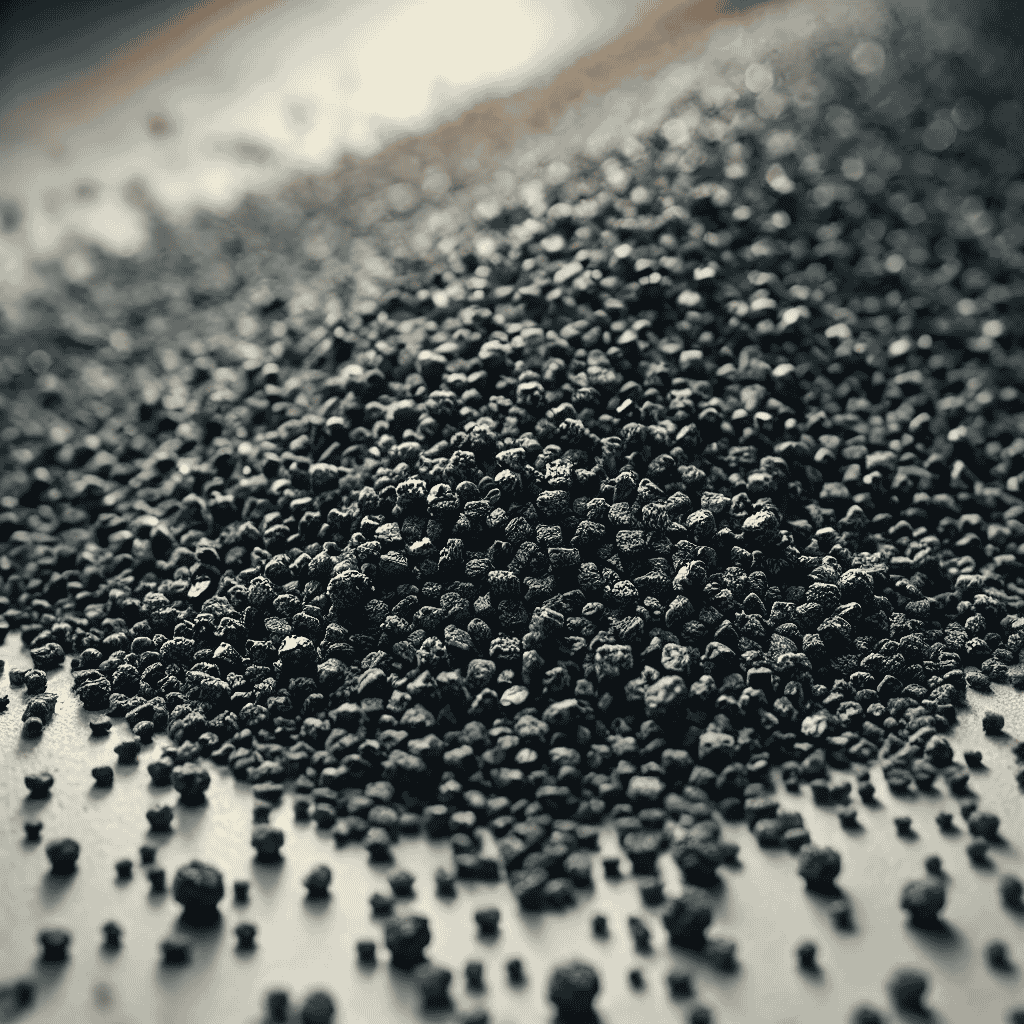

Activated carbon, a highly porous material, plays a vital role across a wide range of industries due to its exceptional adsorption properties. From water purification and air filtration to applications in the food, pharmaceutical, and energy sectors, activated carbon is essential for removing contaminants, improving air quality, and facilitating chemical reactions. The global demand for activated carbon has been steadily increasing, driven by stringent environmental regulations and the growing need for cleaner, more efficient filtration solutions.

This analysis will provide an in-depth look at the activated carbon manufacturing industry, focusing on key trends, technological innovations, and the evolving market landscape. We will explore how activated carbon manufacturers are adapting to the rising demand and regulatory pressures, offering real-life examples, actionable insights, and best practices for leveraging the potential of this critical material in business.

Now Get Sample PDF Report on : Activated Carbon Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=56155

Top 10 Trends in Activated Carbon Manufacturing

Growing Demand for Activated Carbon in Water Purification

Water purification remains one of the largest applications for activated carbon, particularly as global concerns over water scarcity and contamination intensify. Activated carbon’s ability to adsorb organic compounds, chlorine, and heavy metals makes it an ideal material for treating drinking water, industrial wastewater, and municipal water supplies.

Manufacturers are expanding their production capacities to meet the increasing demand from water treatment plants and households. For example, in developing regions where access to clean water remains a challenge, governments are investing in large-scale water purification systems that rely on activated carbon. As concerns over water quality continue to rise, this trend is expected to drive significant growth in the market for activated carbon.

Stricter Environmental Regulations Driving Air Filtration Applications

Environmental regulations aimed at reducing air pollution are a key driver of demand for activated carbon in air filtration applications. In industries such as power generation, chemical manufacturing, and automotive, the need to reduce harmful emissions of volatile organic compounds (VOCs), mercury, and other pollutants is pushing manufacturers to adopt activated carbon filters.

In the automotive industry, for instance, activated carbon is widely used in cabin air filters and fuel vapor recovery systems to reduce emissions and improve air quality inside vehicles. As governments around the world impose stricter emissions standards, manufacturers of activated carbon are focusing on producing more efficient and cost-effective filtration solutions to meet regulatory requirements.

Advancements in Regeneration and Reuse Technologies

One of the emerging trends in the activated carbon market is the development of regeneration technologies, which allow for the reuse of activated carbon after it has been saturated with contaminants. Thermal regeneration is one of the most commonly used methods, where activated carbon is heated to high temperatures to remove adsorbed contaminants, restoring its adsorption capacity.

By enabling multiple cycles of use, regeneration technologies help reduce the environmental impact and operational costs of activated carbon filtration systems. Activated carbon manufacturers are investing in these technologies to offer more sustainable and cost-effective solutions to their customers, particularly in industries where continuous filtration is required, such as in wastewater treatment and industrial emissions control.

Growth in Activated Carbon for Food and Beverage Industry

The food and beverage industry is increasingly using activated carbon for processes such as decolorization, deodorization, and contaminant removal. Activated carbon is widely used in the purification of sweeteners, alcoholic beverages, edible oils, and other food products, where it helps remove impurities without affecting the taste or quality of the final product.

For instance, sugar refining companies use activated carbon to remove colorants and impurities from raw sugar, ensuring a pure, white product. Beverage manufacturers use activated carbon to eliminate undesirable odors and flavors in spirits like vodka and whiskey. As consumer demand for high-quality, contaminant-free products continues to rise, activated carbon manufacturers are positioning themselves to serve this growing market.

Rising Applications in Pharmaceuticals and Healthcare

The pharmaceutical industry relies on activated carbon for a range of applications, including purification, drug formulation, and as an antidote in medical treatments. Activated carbon is used to adsorb impurities in the production of pharmaceuticals, ensuring the purity of active ingredients. In healthcare, activated carbon is used in drug overdoses and poisoning treatments, where it binds to toxins in the digestive system, preventing their absorption into the bloodstream.

As the pharmaceutical industry continues to grow, driven by the increasing demand for medications and vaccines, activated carbon manufacturers are expanding their portfolios to include products tailored to pharmaceutical applications. The continued growth of the healthcare and pharmaceutical sectors presents a lucrative opportunity for activated carbon manufacturers.

Sustainability and the Use of Renewable Raw Materials

Sustainability is becoming a major focus in the activated carbon industry, as manufacturers seek to reduce their environmental footprint. Traditionally, activated carbon is produced from non-renewable sources such as coal and peat. However, there is a growing trend toward using renewable raw materials such as coconut shells, wood, and agricultural by-products for activated carbon production.

Coconut-shell-based activated carbon, in particular, is gaining popularity due to its high hardness, large surface area, and sustainable sourcing. Manufacturers that prioritize the use of renewable raw materials are positioning themselves to meet the demands of environmentally conscious consumers and industries looking to reduce their reliance on fossil fuels.

Activated Carbon for Energy Storage and Supercapacitors

Another exciting application for activated carbon is in energy storage devices such as supercapacitors. Activated carbon’s high surface area and excellent electrical conductivity make it an ideal material for storing energy in supercapacitors, which are used in a variety of applications, including electric vehicles, renewable energy systems, and consumer electronics.

The global shift toward cleaner energy and electric vehicles is driving the demand for advanced energy storage solutions. Activated carbon manufacturers are investing in research and development to create high-performance materials for supercapacitors and other energy storage devices. As the demand for electric vehicles and renewable energy systems continues to grow, the role of activated carbon in energy storage is expected to expand.

Technological Advancements in Manufacturing Processes

Technological innovations in activated carbon production are enabling manufacturers to improve the quality and performance of their products while reducing production costs. Advanced manufacturing processes, such as steam activation and chemical activation, allow for more efficient production of activated carbon with tailored properties for specific applications.

Additionally, manufacturers are investing in automation and process optimization technologies to enhance production efficiency, reduce waste, and improve consistency. These advancements are helping activated carbon manufacturers meet the growing demand for high-performance products in industries such as water treatment, air filtration, and energy storage.

Geographic Expansion and New Market Opportunities

As demand for activated carbon grows across various industries, manufacturers are expanding their geographic presence to tap into new markets. In regions such as Asia-Pacific, Latin America, and Africa, rapid industrialization and urbanization are driving the need for water purification, air filtration, and environmental remediation solutions. Activated carbon manufacturers are establishing production facilities and distribution networks in these regions to meet local demand.

For example, India’s booming industrial sector and growing environmental regulations are creating a strong demand for activated carbon in water treatment and emissions control. Manufacturers that strategically expand into these emerging markets can benefit from increased sales and market share while helping address critical environmental challenges in these regions.

Collaborations and Strategic Partnerships

The activated carbon industry is seeing a growing number of collaborations and partnerships between manufacturers, research institutions, and end-users. These partnerships are aimed at developing new applications for activated carbon, improving product performance, and addressing specific customer needs.

For instance, activated carbon manufacturers are collaborating with environmental engineering firms to develop customized solutions for industrial wastewater treatment and emissions control. By working closely with customers and research institutions, manufacturers can gain insights into emerging industry trends and develop innovative products that meet the evolving needs of the market.

How Activated Carbon Manufacturers Are Changing the Industry

Activated carbon manufacturers are playing a critical role in addressing some of the world’s most pressing environmental challenges. By providing solutions for water purification, air quality improvement, and sustainable energy storage, activated carbon manufacturers are helping industries reduce their environmental impact while improving operational efficiency.

In industries such as automotive, chemical manufacturing, and energy, activated carbon is being used to meet increasingly stringent environmental regulations. The ability of activated carbon to remove harmful pollutants from air and water is making it an indispensable material for companies looking to reduce emissions and improve sustainability.

Furthermore, the development of regeneration technologies is making activated carbon more sustainable, reducing the need for continuous production of new materials. As manufacturers invest in renewable raw materials and advanced production processes, the industry is becoming more environmentally friendly, aligning with global efforts to reduce carbon emissions and conserve natural resources.

Why Activated Carbon Manufacturers Matter in Today’s Market

Activated carbon manufacturers are essential players in today’s market due to the critical role their products play in environmental protection, public health, and industrial processes. In a world where clean water, air quality, and sustainable energy are top priorities, activated carbon is a key material that helps achieve these goals.

As global environmental regulations become more stringent and industries seek more sustainable solutions, the demand for activated carbon will continue to grow. Manufacturers that prioritize innovation, sustainability, and customer collaboration will be well-positioned to thrive in this expanding market.

For businesses, investing in high-quality activated carbon solutions can improve operational efficiency, ensure regulatory compliance, and reduce environmental impact. By partnering with reputable activated carbon manufacturers, companies can access the latest advancements in filtration and adsorption technology, helping them achieve their sustainability and performance goals.

Best Practices for Leveraging Activated Carbon in Business

- Choose the Right Type of Activated Carbon: Different applications require different types of activated carbon, such as granular, powdered, or pelletized forms. Work with your manufacturer to select the appropriate type of activated carbon based on your specific needs, whether it’s for water purification, air filtration, or chemical processing.

- Consider Regenerated Activated Carbon: If your business requires continuous filtration or adsorption, consider using regenerated activated carbon to reduce operational costs and minimize waste. Regeneration technologies can restore the adsorption capacity of activated carbon, allowing it to be reused in multiple cycles.

- Prioritize Sustainable Sourcing: When selecting an activated carbon supplier, look for manufacturers that prioritize the use of renewable raw materials, such as coconut shells or wood. This not only supports your company’s sustainability goals but also helps reduce the environmental impact of activated carbon production.

- Collaborate with Manufacturers for Customized Solutions: Many activated carbon manufacturers offer customized products tailored to specific industries or applications. Collaborating with your manufacturer to develop a solution that meets your unique requirements can enhance the efficiency and effectiveness of your filtration systems.

- Stay Informed About Regulatory Changes: Environmental regulations are constantly evolving, particularly in industries such as automotive, power generation, and chemical manufacturing. Stay informed about the latest regulations in your industry and work with your activated carbon supplier to ensure that your filtration systems are compliant.

Common Questions About Activated Carbon Manufacturers

- What is activated carbon used for? Activated carbon is used in a wide range of applications, including water purification, air filtration, food and beverage processing, pharmaceuticals, and energy storage. It adsorbs contaminants and impurities, improving the quality of air, water, and other substances.

- How is activated carbon made? Activated carbon is produced by heating carbon-rich materials, such as coal, coconut shells, or wood, to high temperatures in the absence of oxygen. This process, known as activation, creates a highly porous structure that gives activated carbon its adsorption properties.

- Can activated carbon be regenerated? Yes, activated carbon can be regenerated through processes such as thermal regeneration. This involves heating the activated carbon to remove adsorbed contaminants, restoring its adsorption capacity for reuse.

- What industries use activated carbon? Activated carbon is used in a variety of industries, including water treatment, air filtration, food and beverage processing, pharmaceuticals, automotive, and energy storage. Its versatility and effectiveness make it a valuable material in many applications.

- Is activated carbon environmentally friendly? Activated carbon can be environmentally friendly, particularly when produced from renewable raw materials and used in sustainable applications such as air and water purification. Regenerated activated carbon further reduces environmental impact by allowing the material to be reused.

The activated carbon manufacturing industry is evolving in response to rising demand, stricter environmental regulations, and a growing focus on sustainability. From water purification and air filtration to energy storage and food processing, activated carbon plays a critical role in improving environmental outcomes and enhancing industrial efficiency.

As manufacturers continue to innovate and develop new applications for activated carbon, the market is expected to expand further, offering numerous opportunities for businesses to leverage this versatile material. By investing in high-quality activated carbon solutions and collaborating with manufacturers to develop customized products, businesses can optimize their operations, reduce their environmental footprint, and stay ahead of regulatory changes.

The future of the activated carbon market looks promising, with new technologies and sustainable practices paving the way for continued growth and innovation.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices