-

Email Us

- Top Reports

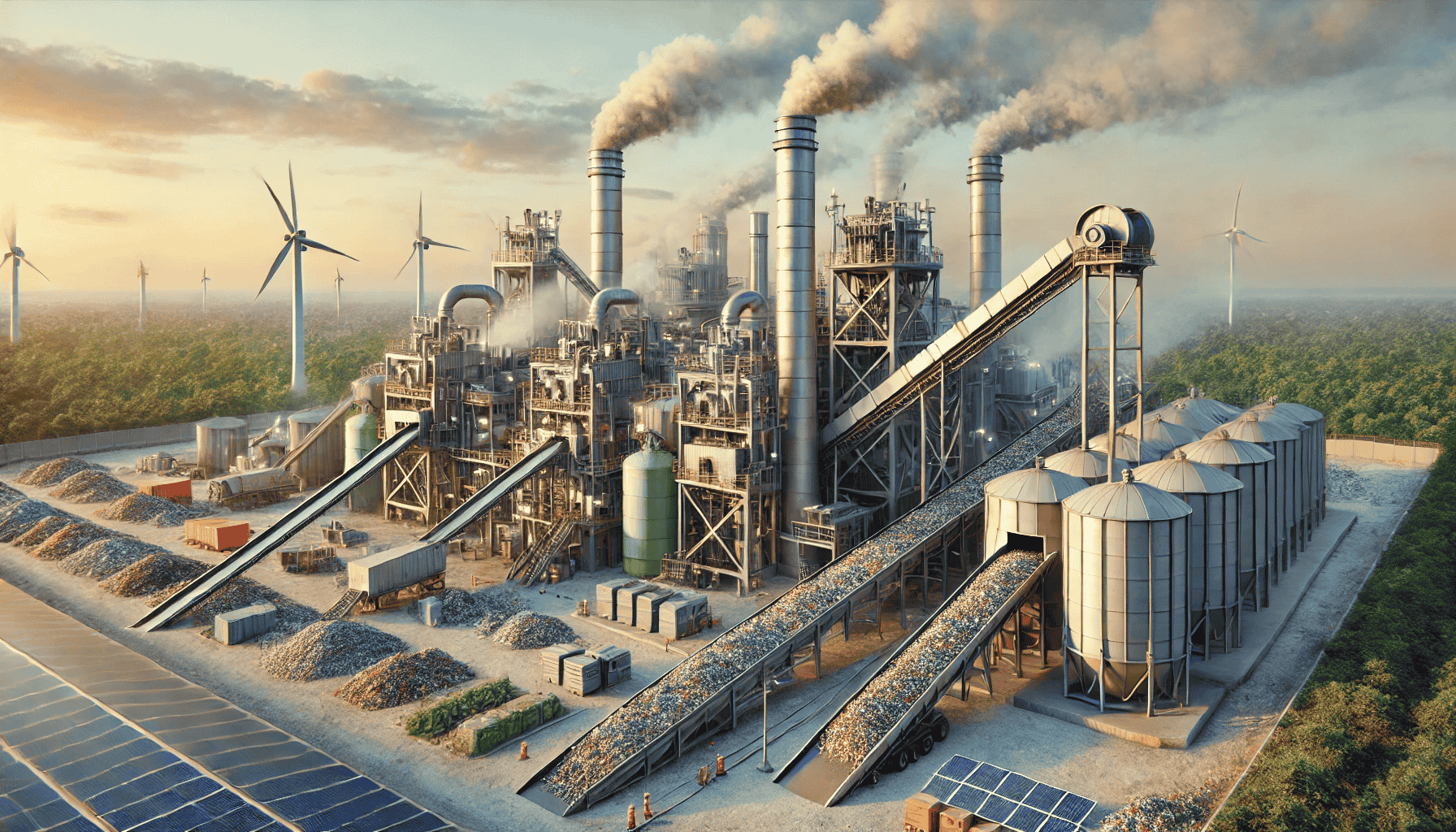

Top 10 Trends in Waste-to-Energy Companies in the USA

Posted On 18 November, 2024

1. Advanced Thermal Conversion Technologies

Advanced thermal conversion technologies, such as gasification and pyrolysis, are transforming waste-to-energy (WtE) by creating clean fuels with minimal pollution. For instance, Covanta has adopted gasification, a process that heats waste materials to high temperatures in a low-oxygen environment to produce syngas—a mixture of hydrogen and carbon monoxide that can fuel electricity generators or be refined into biofuels. Pyrolysis, a related technique, can turn plastic waste into liquid fuels, further contributing to a circular economy by creating renewable alternatives to traditional fossil fuels. These technologies differ significantly from traditional incineration, as they generate fewer emissions and hazardous by-products. With the ability to handle a wide range of waste materials, gasification and pyrolysis are viable for urban waste management, especially in densely populated areas where waste disposal and renewable energy demand are high. These innovations are particularly significant for industrial applications and urban areas requiring sustainable energy solutions.

Thermal conversion technologies address a pressing issue: the environmental impact of waste. Unlike conventional incineration, which releases greenhouse gases and pollutants, gasification and pyrolysis offer cleaner alternatives that yield fewer harmful emissions. As landfill capacity diminishes and pressure mounts to reduce greenhouse gas emissions, these technologies provide a pathway for municipalities and industries to meet sustainability goals. The benefits extend beyond emissions control; they contribute to energy independence by creating usable fuels from waste. These technologies also support circular economy initiatives by creating valuable by-products like biochar and hydrogen, reducing reliance on landfills, and enhancing the energy grid with alternative fuel sources.

Municipalities and businesses can leverage partnerships with WtE companies that specialize in gasification and pyrolysis. Local governments should consider incentives or grants for facilities adopting these technologies, which could attract investment and improve local energy resilience. For companies, prioritizing WtE providers using advanced thermal technologies not only supports their sustainability goals but also offers a predictable waste disposal solution. Hosting or co-locating thermal conversion facilities near industries with substantial waste output could further streamline costs and logistics, making waste disposal more efficient and environmentally friendly.

Now Get Sample PDF Report on : Waste-To-Energy Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=327496

2. Enhanced Emission Control Systems

With rising environmental standards, emission control systems are now fundamental to WtE plants. Babcock & Wilcox, for example, uses selective catalytic reduction (SCR) and activated carbon filters to capture harmful pollutants before they enter the atmosphere. SCR systems effectively reduce nitrogen oxide emissions—a major contributor to smog and acid rain—by converting them into harmless nitrogen and water vapor. Activated carbon filters also trap heavy metals and dioxins. In response to increasingly strict emissions regulations, modern WtE plants are installing these advanced filtration systems, resulting in air quality that meets or even surpasses regulatory requirements. Through these technologies, WtE companies can set up plants closer to populated areas without compromising local air quality, creating more options for city waste management.

Emissions control in WtE is essential for both community health and regulatory compliance. Nitrogen oxides, sulfur oxides, and dioxins are by-products of waste incineration, and without proper treatment, these can contribute to respiratory problems and environmental pollution. Advanced emission controls ensure that WtE facilities have a minimal impact on the surrounding environment. For companies operating near urban centers, such systems can increase social acceptance and reduce opposition to waste-to-energy projects. In addition, investing in emission control upgrades can ensure compliance with federal and state environmental standards, avoiding costly fines and shutdowns that could disrupt operations and impact the bottom line.

Waste-to-energy companies should proactively invest in modern emission control systems to stay compliant and maintain a positive public image. Local governments can prioritize contracts with WtE companies that demonstrate strong environmental commitments, benefiting public health and air quality. Community stakeholders could also engage in informative discussions with WtE providers about emission controls to build local support. Businesses aiming to manage their waste responsibly should ensure that their WtE partners meet or exceed the latest emission standards, as this reflects positively on their own sustainability practices.

3. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are optimizing WtE plant operations by predicting equipment failures, refining waste sorting, and maximizing energy yield. For instance, Clean Energy Fuels uses AI to monitor plant operations, identifying potential maintenance needs before equipment fails. This predictive capability minimizes downtime and extends equipment lifespan. Machine learning algorithms can also analyze waste composition and help sort materials more efficiently, ensuring the highest quality fuel for energy generation. AI-driven waste sorting has become integral to maximizing plant efficiency, reducing manual labor costs, and ensuring safety for plant personnel. With this technology, WtE plants can achieve consistent operations and better manage unpredictable waste streams.

AI and machine learning improve efficiency and cost-effectiveness, making WtE operations more resilient and financially sustainable. Predictive maintenance reduces costly repairs and downtime, allowing continuous energy generation without interruption. By optimizing the sorting process, AI also ensures that only appropriate waste materials are processed, resulting in higher-quality outputs and reducing environmental hazards. The benefits extend to workforce safety, as AI can handle hazardous sorting tasks. As WtE companies embrace these technologies, they create models for data-driven waste management that others in the industry can replicate, contributing to overall industry advancement.

Waste-to-energy companies should assess their technology infrastructure and consider implementing AI solutions for predictive maintenance and waste sorting. Facilities that adopt AI-powered systems may benefit from increased operational efficiency, cost savings, and reduced environmental impact. Staff training on AI integration will ensure these systems are effectively utilized. Additionally, local governments could offer incentives for WtE companies adopting AI, as this aligns with urban sustainability goals by promoting efficient and sustainable waste processing.

4. Diversified Energy Production

In response to evolving energy demands, some WtE facilities are producing diverse energy types, from biofuels to hydrogen. Enerkem, a prominent WtE company, converts non-recyclable waste into methanol and ethanol, both of which can be used as biofuels. Covanta is exploring hydrogen production by refining gases created during waste conversion. By offering alternative fuels, these companies provide energy resources that can support transportation, heating, and electricity, depending on market needs. This diversification reduces dependency on traditional energy sources, helping facilities remain viable as renewable energy markets evolve. With this model, facilities cater to various sectors, from automotive to industrial applications.

Producing multiple types of energy from waste enables companies to be more adaptable and resilient in the face of fluctuating energy demands. As demand for biofuels and hydrogen rises, WtE companies can become important players in reducing the carbon footprint of energy-intensive industries. This flexibility also creates multiple revenue streams, enhancing financial stability for WtE operators. As society shifts to more sustainable energy sources, facilities that can pivot between electricity, biofuels, and hydrogen will be better positioned to meet these demands and sustain long-term growth.

Municipalities can support WtE companies that offer diversified energy outputs by creating frameworks that encourage biofuel and hydrogen development. By incentivizing the production of alternative fuels, cities can promote local energy independence and reduce reliance on fossil fuels. Businesses that rely on biofuels or hydrogen can also partner with these WtE providers to secure stable fuel sources, especially as renewable energy transitions accelerate. Investing in diversified WtE providers can therefore offer resilience to energy-dependent industries.

5. Carbon Capture and Utilization

Carbon capture and utilization (CCU) in waste-to-energy plants captures CO₂ emissions from waste combustion and transforms them into useful products, such as building materials or biofuels. Companies like Archaea Energy are pioneering CCU technology by capturing carbon dioxide from waste combustion and converting it into methane for use as renewable natural gas (RNG). Another company, NET Power, has developed a process to capture nearly all CO₂ emissions during waste conversion, which is then used to create materials like concrete and synthetic fuels. This approach allows WtE plants to offset emissions, turning waste processing into a more sustainable and environmentally friendly operation.

CCU technology is essential for reducing the carbon footprint of WtE operations, addressing one of the main criticisms of waste-to-energy: greenhouse gas emissions. By capturing and reusing carbon, these facilities can contribute to a circular economy and create a cleaner, more sustainable energy source. Additionally, CCU can provide a new revenue stream for WtE companies by allowing them to sell carbon-based products. As companies strive to meet climate targets and adhere to stricter regulations on emissions, CCU can position WtE companies as leaders in sustainable waste management and renewable energy production, helping the U.S. achieve its climate goals.

Waste-to-energy companies should consider investing in CCU technologies to both meet environmental standards and monetize captured carbon. Cities and local governments can create incentives for WtE plants that integrate CCU systems, offering grants or tax benefits to those that reduce their emissions. Businesses with high carbon footprints can form partnerships with WtE providers using CCU, helping offset their emissions by sourcing energy from cleaner waste-to-energy providers. This alignment can boost both parties’ sustainability profiles, providing mutual benefits and enhancing corporate social responsibility efforts.

6. Focus on Plastics-to-Fuel Conversion

The plastics-to-fuel conversion trend addresses the growing issue of plastic waste by turning it into energy-dense fuel. Companies such as Agilyx and Brightmark Energy use chemical recycling techniques to break down plastics into fuels like diesel, kerosene, and gasoline. By converting plastics that would otherwise pollute landfills and oceans, these companies help alleviate the plastic waste crisis while contributing to the renewable energy supply. For instance, Brightmark operates a plant in Indiana capable of converting 100,000 tons of plastic waste into fuel each year. These plastics-to-fuel systems use pyrolysis to break down plastic at high temperatures, yielding fuel that can replace conventional petroleum products.

With global plastic pollution reaching critical levels, plastics-to-fuel technology offers a practical and scalable solution to manage plastic waste. By diverting plastics from landfills, WtE companies can help reduce environmental contamination, making a positive impact on ecosystems and public health. Plastics-to-fuel also supports energy production without relying on fossil fuels, contributing to a more sustainable energy economy. Moreover, it’s an opportunity for WtE companies to turn a challenging waste stream into a valuable resource, enhancing their revenue and aligning with both environmental goals and the demand for renewable fuels.

Actionable Tip:

Waste-to-energy companies should explore partnerships with municipalities and waste management firms to secure a steady stream of plastic waste for conversion. Businesses in industries generating significant plastic waste could also collaborate with WtE providers to improve their own waste disposal. Government incentives can encourage WtE companies to adopt plastics-to-fuel technology, which benefits local economies and reduces landfill burdens. Educating the public about plastic recycling can further enhance the supply of waste plastics for fuel conversion, supporting a robust, circular waste management system.

7. Hybrid WtE Systems with Renewable Energy Integration

Hybrid WtE systems combine traditional waste-to-energy processes with renewable energy sources like solar or wind. For example, Covanta has begun integrating solar panels at some of its WtE facilities to supplement the energy produced from waste combustion. This approach not only maximizes energy output but also creates a more resilient energy system by balancing the intermittent nature of renewables with continuous waste processing. By combining these sources, WtE plants can stabilize energy output to the grid and reduce reliance on fossil fuels, contributing to a cleaner, more sustainable energy landscape.

Hybrid systems enhance the sustainability of WtE operations by reducing dependence on waste alone for energy production. They support energy diversification and create stability in the power supply by balancing renewable sources with WtE. Hybridization also helps meet demand more effectively, particularly in regions where renewables alone may not be sufficient. As energy grids adapt to incorporate more renewables, hybrid WtE systems can be a valuable addition to regional grids, supporting energy security and improving grid resilience.

Actionable Tip:

Waste-to-energy companies should assess opportunities to install renewable energy sources at their facilities. Local governments could support these integrations through grants or partnerships, helping WtE companies offset the costs of renewable installation. Collaborations with renewable energy companies can make hybrid systems more feasible and financially viable. WtE companies should also communicate these hybrid benefits to consumers, enhancing their reputation and attracting environmentally conscious customers.

8. Use of Blockchain for Transparency and Efficiency

Blockchain technology offers transparency and efficiency in tracking waste sources, processing stages, and energy output within WtE facilities. Companies like Circulor have started using blockchain to monitor waste throughout the recycling and energy conversion process, ensuring accountability and tracking emissions reductions. Blockchain enables transparent reporting of waste origins, emissions data, and energy output, providing insights to regulators and stakeholders. It also helps companies manage carbon credits by accurately recording emissions reductions, which can be traded or used to meet sustainability targets. By integrating blockchain, WtE companies can provide verifiable data on their environmental impact.

Transparency and accountability are increasingly important in waste management, especially for companies aiming to prove their environmental responsibility. Blockchain provides a secure, immutable record of waste processing and emissions, which can improve public trust and regulatory compliance. This transparency is crucial for companies claiming carbon credits and meeting ESG (Environmental, Social, Governance) criteria. Blockchain can also improve operational efficiency by identifying bottlenecks and streamlining waste processing, contributing to higher productivity and cost savings.

WtE companies should evaluate blockchain solutions that fit their needs, prioritizing those that can integrate with existing waste management and reporting systems. They may also consider working with blockchain startups focused on environmental applications to develop customized solutions. Collaborating with municipal waste departments could further increase blockchain adoption by ensuring all waste data is logged transparently from source to processing. This integration could serve as a model for other industries looking to boost accountability and data integrity.

9. Growth of Small-Scale and Decentralized WtE Plants

Decentralized WtE plants are small-scale facilities situated closer to waste sources, reducing the need for long-haul waste transportation. Companies like WtEnergy have established modular WtE plants that can be easily set up in urban areas to process local waste. These facilities reduce transportation emissions and costs by processing waste onsite and supplying energy directly to nearby consumers or businesses. Small-scale plants are particularly beneficial for areas with limited infrastructure, allowing waste to be managed locally, minimizing landfill use, and producing energy more efficiently.

Small-scale WtE plants can make waste management more accessible and sustainable by eliminating transportation-related emissions. They provide a solution for rural and urban communities alike, enhancing waste management without the need for large facilities. Decentralized plants also create energy independence, allowing communities to produce their own power from waste. With flexible setups, small-scale plants can be more adaptable and responsive to local waste needs, contributing to resilient and localized waste and energy solutions.

Communities and local governments could support small-scale WtE facilities by identifying waste-heavy areas and encouraging private sector investment. Rural regions, in particular, could benefit from modular WtE plants that reduce waste transportation needs and costs. For waste-to-energy companies, exploring mobile or modular plant designs could allow them to serve underserved areas efficiently, establishing a niche within decentralized waste management.

10. Focus on Zero-Waste and Circular Economy Initiatives

Zero-waste and circular economy principles aim to maximize waste resource efficiency and minimize landfill use. Some companies, like Covanta, partner with manufacturers to divert waste from landfills entirely, either recycling it or turning it into energy. By aligning with zero-waste initiatives, WtE plants become part of a circular system where waste is continuously recycled or repurposed into new materials and energy. Covanta’s zero-waste programs help clients achieve up to 95% waste diversion rates, reinforcing the idea that waste has residual value and potential energy.

The shift towards zero-waste supports a circular economy that aims to eliminate waste and repurpose materials. This approach contributes to sustainable development and resource efficiency, which are essential in reducing environmental impact. For companies, adopting zero-waste practices aligns them with consumer expectations for environmentally responsible operations, enhancing their public image. Zero-waste initiatives also create cost savings and contribute to long-term environmental benefits by reducing dependency on virgin materials and fossil fuels.

WtE providers should engage with businesses to develop zero-waste plans that prioritize waste reduction, recycling, and energy recovery. Collaborating with manufacturers and local governments on zero-waste initiatives can help close the loop on waste management. Public education campaigns can further promote zero-waste efforts, helping people understand the value of resource recovery and supporting waste reduction at the source.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices