-

Email Us

- Top Reports

A Comprehensive Analysis of Polypropylene Fibers: Industry Trends, Insights, and Best Practices

Posted On 11 October, 2024

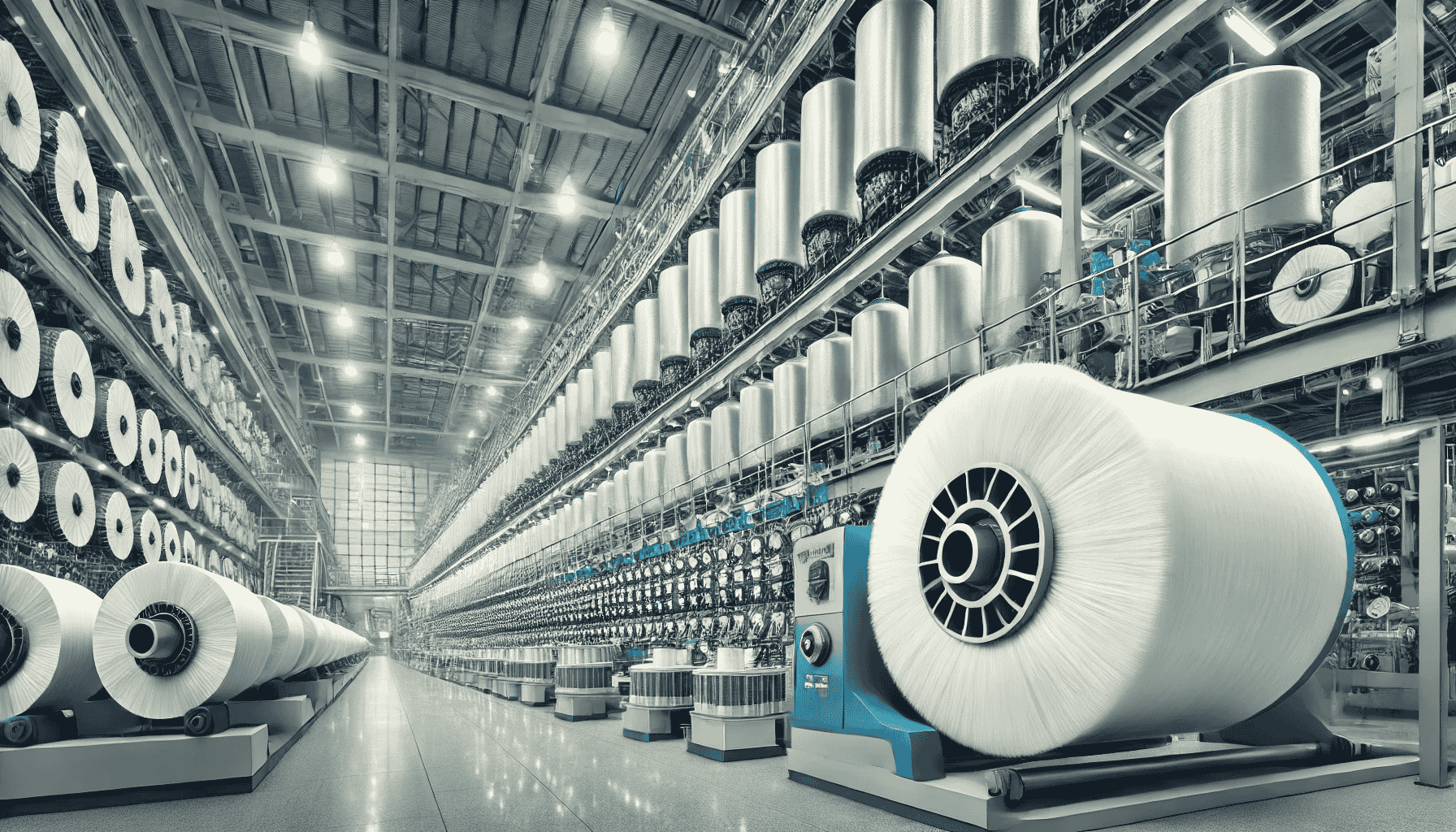

Polypropylene fibers have become a key player in various industries, offering numerous advantages such as durability, resistance to moisture, and versatility in applications. From construction materials and automotive components to textiles and geotextiles, polypropylene fibers provide a cost-effective and efficient solution for many businesses. As industries evolve, the demand for high-performance materials like polypropylene fibers continues to grow, leading to significant advancements in production processes, applications, and sustainability initiatives.

This comprehensive analysis will explore the latest trends in polypropylene fibers, their impact on different industries, and why they are critical in today’s market. We will also discuss best practices for leveraging polypropylene fibers to maximize their potential in business.

Now Get Sample PDF Report on : Polypropylene Fiber Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=232265

Top 10 Trends in Polypropylene Fibers

The use of polypropylene fibers is rapidly expanding due to technological advancements, changing consumer demands, and new industrial applications. Here are the top 10 trends shaping the polypropylene fiber industry:

1. Growth in Construction and Infrastructure Projects

One of the most prominent trends in polypropylene fibers is their increasing use in the construction and infrastructure sectors. Polypropylene fibers are commonly used in concrete reinforcement, geotextiles, and erosion control applications due to their high tensile strength and resistance to chemicals. As global infrastructure projects, such as roads, bridges, and commercial buildings, continue to grow, the demand for polypropylene fibers is rising.

Polypropylene fibers offer significant advantages over traditional materials, such as steel reinforcement, by providing lightweight, non-corrosive, and cost-effective alternatives. This trend is expected to continue as governments invest in large-scale infrastructure projects.

2. Demand for Sustainable and Eco-Friendly Materials

With an increasing focus on sustainability and environmental responsibility, polypropylene fibers are gaining attention for their potential in eco-friendly applications. Polypropylene is a recyclable thermoplastic, making it a more sustainable option compared to other materials. Many manufacturers are working to improve the recyclability and life cycle of polypropylene fibers, reducing waste and minimizing their environmental impact.

This growing emphasis on sustainability is driving innovation in polypropylene fiber production, particularly in industries such as textiles and packaging, where eco-friendly solutions are in high demand.

3. Expansion in Automotive Lightweighting

Polypropylene fibers are becoming a popular choice for lightweight automotive components. In the automotive industry, manufacturers are continually seeking ways to reduce vehicle weight to improve fuel efficiency and reduce emissions. Polypropylene fibers offer an ideal solution due to their lightweight nature, strength, and resistance to heat and chemicals.

From interior upholstery and carpets to exterior components and insulation, polypropylene fibers are helping automotive manufacturers achieve their lightweighting goals. This trend is particularly important as electric vehicles (EVs) become more prominent, with polypropylene fibers playing a role in extending battery life and enhancing overall vehicle performance.

4. Increased Use in Filtration Products

Filtration is another industry benefiting from the unique properties of polypropylene fibers. Due to their chemical resistance, hydrophobic nature, and ability to withstand high temperatures, polypropylene fibers are widely used in industrial and medical filtration systems. These fibers are effective in water, air, and liquid filtration, making them essential for sectors such as pharmaceuticals, food and beverage, and manufacturing.

The demand for high-quality filtration products continues to grow as industries prioritize cleanliness, safety, and environmental protection, positioning polypropylene fibers as a key material in the filtration market.

5. Growing Demand in Nonwoven Fabrics

Nonwoven fabrics made from polypropylene fibers are gaining popularity in various applications, including medical textiles, hygiene products, and packaging. Polypropylene fibers are used to create disposable masks, surgical gowns, diapers, and sanitary products due to their strength, softness, and moisture resistance. The COVID-19 pandemic highlighted the importance of nonwoven fabrics, increasing the demand for personal protective equipment (PPE) made from polypropylene fibers.

This trend shows no signs of slowing down, as nonwoven fabrics continue to find new applications in hygiene, healthcare, and industrial sectors.

6. Innovations in Textile Applications

The textile industry is seeing increased use of polypropylene fibers in clothing, home textiles, and outdoor gear. Polypropylene fibers offer moisture-wicking, quick-drying, and insulating properties, making them ideal for activewear, sportswear, and thermal garments. Additionally, polypropylene fibers are resistant to stains, mildew, and fading, making them suitable for upholstery, carpets, and outdoor furniture.

As consumers seek durable, low-maintenance fabrics, the textile industry is adopting polypropylene fibers in innovative ways to create high-performance products.

7. Focus on Fire-Resistant Polypropylene Fibers

Fire resistance is becoming an important consideration for many industries, particularly in construction and textiles. Polypropylene fibers are being modified to improve their fire-retardant properties, making them suitable for applications in fire-resistant fabrics, protective clothing, and building materials. These advancements in fire-resistant polypropylene fibers are meeting the increasing demand for materials that prioritize safety without compromising performance.

This trend is especially relevant in sectors where fire hazards are a concern, such as construction, transportation, and energy.

8. Advancements in Production Techniques

Polypropylene fiber manufacturers are continually refining production techniques to improve the quality, durability, and cost-effectiveness of their products. Technological advancements such as melt spinning, fiber extrusion, and automated processing are enhancing the efficiency of polypropylene fiber production. These innovations are reducing manufacturing costs and improving the consistency and performance of polypropylene fibers.

As production techniques continue to evolve, manufacturers can scale up their operations and meet the growing demand for polypropylene fibers across multiple industries.

9. Integration into 3D Printing

Polypropylene fibers are being integrated into 3D printing technologies, enabling the creation of strong, lightweight, and flexible components. 3D printing with polypropylene fibers is becoming increasingly popular in prototyping and product development across industries like automotive, aerospace, and medical devices. This integration allows manufacturers to produce custom parts with enhanced durability and precision.

The use of polypropylene fibers in 3D printing is expected to grow as advancements in additive manufacturing open new possibilities for customized, high-performance products.

10. Focus on Biodegradable Polypropylene Alternatives

While polypropylene is known for its recyclability, there is growing interest in developing biodegradable alternatives to traditional polypropylene fibers. Researchers and manufacturers are exploring ways to create bio-based polypropylene that maintains the performance characteristics of conventional polypropylene while offering improved environmental benefits. These biodegradable polypropylene fibers could reduce plastic waste and contribute to a more sustainable future for industries that rely on this versatile material.

This trend reflects the broader industry shift toward materials that minimize environmental impact while maintaining high performance.

How Polypropylene Fibers Are Changing the Industry

Polypropylene fibers are transforming industries by offering a unique combination of strength, flexibility, and resistance to wear and tear. In the construction industry, polypropylene fibers are replacing traditional steel reinforcements in concrete, resulting in stronger, more durable structures that are easier to install and maintain. In textiles, polypropylene fibers are enabling the production of moisture-wicking, quick-drying clothing that meets the demands of active consumers.

The automotive industry is also benefiting from polypropylene fibers, using them to produce lightweight components that improve fuel efficiency and reduce emissions. The versatility of polypropylene fibers allows them to be used in a wide range of applications, from geotextiles and filtration products to furniture and industrial packaging.

As industries continue to evolve, polypropylene fibers are helping businesses meet new challenges by providing high-performance, cost-effective solutions that are durable, lightweight, and environmentally friendly.

Why Polypropylene Fibers Matter in Today’s Market

Polypropylene fibers are essential in today’s market for several reasons. First, they provide a versatile and durable material that can be used in various industries, from construction and automotive to textiles and healthcare. Their unique properties, such as resistance to moisture, chemicals, and UV radiation, make them suitable for demanding applications where traditional materials may not perform as well.

Additionally, polypropylene fibers contribute to the growing demand for sustainable materials. As more industries prioritize eco-friendly solutions, polypropylene fibers offer a recyclable option that helps reduce waste and lower the environmental impact of manufacturing. This focus on sustainability is increasingly important as businesses and consumers alike seek products that align with their environmental values.

Furthermore, polypropylene fibers are helping industries improve efficiency and performance. Their lightweight nature reduces transportation costs and energy consumption, while their durability ensures that products made from polypropylene fibers have a longer lifespan. These factors make polypropylene fibers a valuable asset in industries looking to optimize their operations and reduce costs.

Best Practices for Leveraging Polypropylene Fibers in Business

For businesses looking to take advantage of the benefits of polypropylene fibers, there are several best practices to consider:

- Partner with Reliable Suppliers: Work with suppliers that specialize in high-quality polypropylene fibers and have experience in your industry. This ensures that you receive consistent, reliable products that meet your specific needs.

- Focus on Innovation: Polypropylene fibers offer a wide range of possibilities for innovation. Explore new applications and production techniques that allow you to leverage the material’s unique properties. Whether it’s creating new textile products or developing fire-resistant building materials, innovation can set your business apart in a competitive market.

- Prioritize Sustainability: As the demand for eco-friendly materials grows, it’s important to prioritize sustainability in your use of polypropylene fibers. Look for ways to incorporate recycled polypropylene into your products and explore biodegradable alternatives that align with environmental goals.

- Stay Informed on Industry Trends: The polypropylene fiber industry is constantly evolving, with new trends and technologies emerging regularly. Stay informed about the latest developments to ensure your business remains competitive and takes full advantage of the opportunities polypropylene fibers present.

- Optimize for Cost Efficiency: One of the key benefits of polypropylene fibers is their cost-effectiveness. By optimizing your use of polypropylene fibers, you can reduce material costs and improve the overall efficiency of your production processes.

In conclusion, polypropylene fibers are transforming industries by providing a versatile, durable, and sustainable material that can be used in a wide range of applications. As the demand for high-performance materials continues to grow, polypropylene fibers will play an increasingly important role in helping businesses meet the challenges of today’s market. By staying ahead of industry trends and adopting best practices, businesses can leverage polypropylene fibers to enhance their products and gain a competitive edge in their respective industries.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices