-

Email Us

- Top Reports

A Comprehensive Analysis of Abrasives Manufacturers: Trends, Industry Insights, and Best Practices

Posted On 11 October, 2024

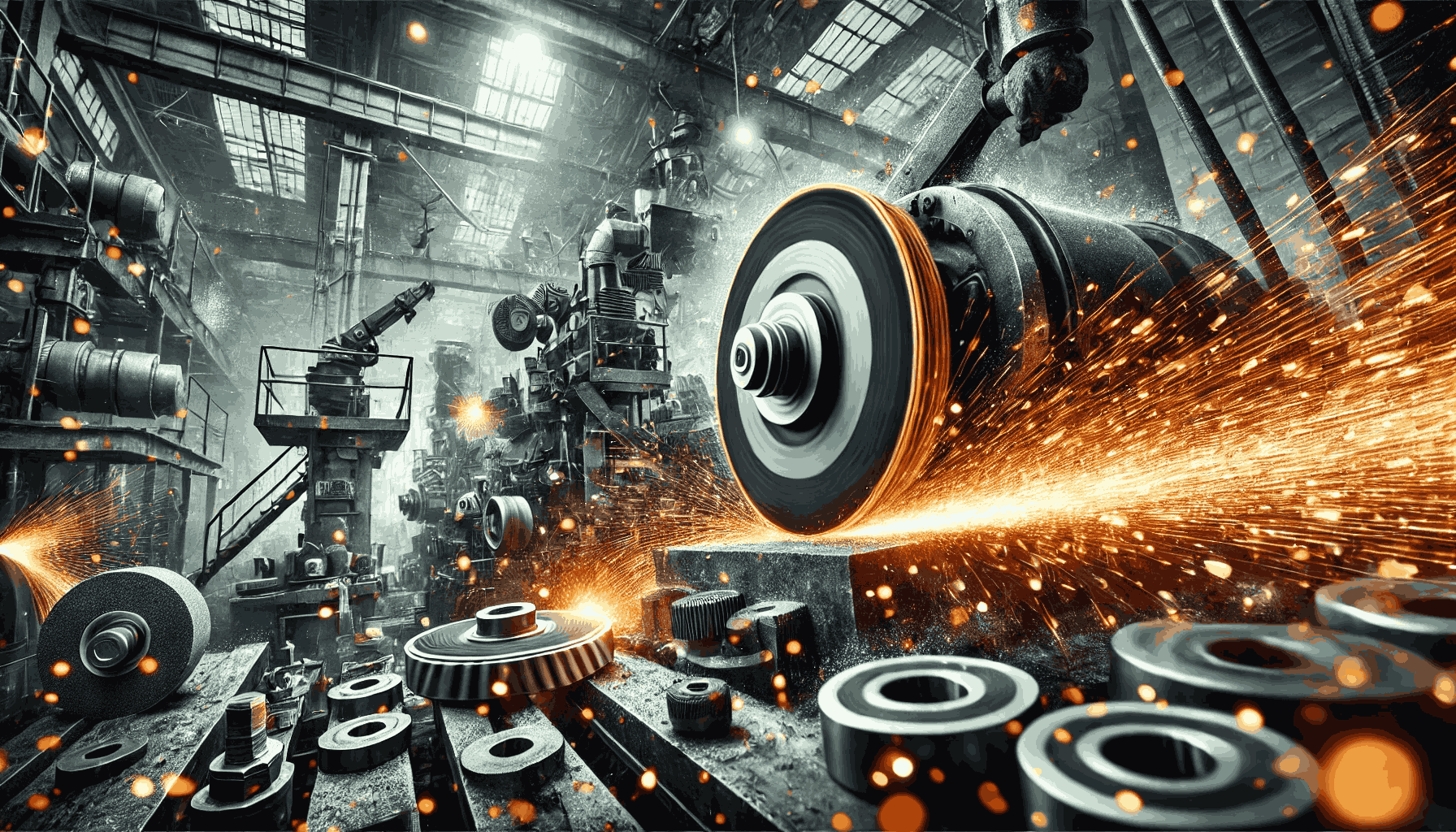

Abrasives are critical in a variety of industrial and consumer applications, providing the essential cutting, grinding, polishing, and surface finishing capabilities required for many processes. From metalworking and construction to automotive and electronics industries, abrasives play a key role in manufacturing and production. Abrasive manufacturers, therefore, have a significant responsibility in supplying high-performance products to meet the demands of numerous sectors. With technological advancements and growing market trends, the abrasives industry has evolved to incorporate new materials, processes, and applications.

This analysis aims to provide an in-depth look at abrasives manufacturers, discuss current industry trends, and highlight their impact on the market. Additionally, we will explore why abrasives manufacturers are essential in today’s global economy and offer insights into best practices for businesses looking to capitalize on the growing abrasives market.

Now Get Sample PDF Report on : Abrasive Materials Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=205961

Top 10 Trends in Abrasives Manufacturers

The abrasives industry is evolving rapidly, influenced by advancements in materials science, changing consumer demands, and industrial needs. Here are the top 10 trends shaping the abrasives manufacturing landscape:

1. Adoption of Advanced Materials

One of the most significant trends in abrasives manufacturing is the adoption of advanced materials. While traditional abrasives like aluminum oxide and silicon carbide remain widely used, manufacturers are increasingly turning to more specialized materials like synthetic diamonds, cubic boron nitride (CBN), and ceramic abrasives. These advanced materials offer enhanced performance, longer life spans, and better efficiency, especially in high-precision applications such as aerospace and electronics.

As industries demand more durable and efficient abrasives, manufacturers are continuously researching and developing new materials to meet these requirements.

2. Growth of Coated Abrasives

Coated abrasives, which consist of abrasive grains adhered to a backing material such as paper, cloth, or plastic, are experiencing significant growth. These abrasives are commonly used in sanding and finishing applications across industries such as woodworking, metalworking, and automotive. The versatility and ease of use of coated abrasives have led to an increase in their adoption for both industrial and DIY applications.

Manufacturers are developing new types of coated abrasives with improved flexibility, durability, and performance, further driving demand in this segment.

3. Increased Focus on Sustainability

Sustainability is becoming a key consideration for abrasives manufacturers. As environmental regulations tighten and industries look to reduce their carbon footprint, manufacturers are focusing on producing eco-friendly abrasives. This includes using recycled materials in production, minimizing waste during manufacturing, and creating products that are more durable and require less frequent replacement.

In addition, there is growing interest in water-based and solvent-free adhesives used in coated abrasives, which reduce the environmental impact of the production process.

4. Digitalization and Automation in Manufacturing

Digitalization and automation are transforming the abrasives manufacturing process, leading to greater efficiency and precision. Smart manufacturing techniques such as automated production lines, AI-driven quality control, and data analytics are helping manufacturers optimize production processes, reduce costs, and improve product quality. Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows for greater customization and flexibility in product development.

Automation is also playing a critical role in enhancing safety in abrasive manufacturing, reducing human error, and minimizing accidents during production.

5. Increasing Demand for Precision and Super Abrasives

As industries like electronics, aerospace, and medical devices demand more precision in manufacturing processes, the use of super abrasives such as synthetic diamonds and CBN is growing. These abrasives offer superior cutting and grinding capabilities, enabling manufacturers to achieve extremely tight tolerances and high surface finishes. Super abrasives are also ideal for machining hard and brittle materials, such as ceramics and composites, which are commonly used in advanced manufacturing.

Manufacturers are investing heavily in the development of super abrasives to meet the needs of high-precision industries, which are expected to continue growing in the coming years.

6. Growth of the Automotive Sector

The automotive industry remains one of the largest consumers of abrasives, using them in a wide range of applications from metalworking and surface finishing to painting and polishing. The growth of electric vehicles (EVs) is also driving demand for abrasives, as new materials like lightweight alloys and composites are being used in EV production. Abrasives manufacturers are developing products specifically designed to work with these new materials, ensuring that they can meet the unique challenges posed by the automotive sector.

Additionally, the automotive aftermarket, including repair and refinishing services, continues to be a major driver of demand for abrasives.

7. Expansion into Emerging Markets

Emerging markets, particularly in Asia-Pacific, Latin America, and Africa, are becoming increasingly important for abrasives manufacturers. Rapid industrialization, infrastructure development, and urbanization in these regions are driving demand for abrasives in sectors such as construction, automotive, and manufacturing. Abrasives manufacturers are expanding their operations in these regions, establishing new production facilities, and partnering with local distributors to capture growing market opportunities.

By focusing on emerging markets, manufacturers can diversify their revenue streams and reduce their reliance on mature markets in Europe and North America.

8. Customized Solutions for Industry-Specific Applications

As industries become more specialized, there is a growing demand for customized abrasive solutions that are tailored to specific applications. Manufacturers are working closely with end-users to develop abrasives that meet the unique requirements of industries such as aerospace, electronics, and medical devices. These customized solutions may involve specific material compositions, unique bonding technologies, or specialized grain sizes.

By offering tailored solutions, abrasives manufacturers can differentiate themselves in a competitive market and build long-term relationships with customers.

9. Integration of Sustainable Manufacturing Practices

Sustainable manufacturing practices are becoming a key focus for abrasives manufacturers. Companies are adopting energy-efficient production processes, reducing water and chemical usage, and minimizing waste during production. Additionally, many manufacturers are seeking certifications such as ISO 14001 to demonstrate their commitment to environmental sustainability.

This focus on sustainability is not only helping manufacturers reduce their environmental impact but also improving their competitiveness as more customers prioritize eco-friendly products.

10. Innovation in Bonding and Coating Technologies

Advancements in bonding and coating technologies are helping to improve the performance and durability of abrasives. Manufacturers are developing new bonding agents that offer better heat resistance, increased toughness, and improved adhesion between abrasive grains and the backing material. These innovations are particularly important in high-stress applications, where abrasives must withstand extreme temperatures and pressures.

The development of advanced coatings is also enhancing the efficiency and lifespan of abrasives, allowing them to deliver consistent performance over extended periods of use.

How Abrasives Manufacturers Are Changing the Industry

Abrasives manufacturers are driving significant changes in the industrial landscape by developing products that enhance productivity, efficiency, and sustainability. One of the most notable ways that abrasives manufacturers are changing the industry is through their focus on innovation. The development of advanced materials, super abrasives, and customized solutions is enabling industries to achieve higher levels of precision and performance in their manufacturing processes.

In addition to innovation, abrasives manufacturers are helping industries become more sustainable by producing eco-friendly products and adopting sustainable manufacturing practices. The focus on sustainability is critical as industries face increasing pressure to reduce their environmental impact while maintaining high levels of productivity.

Abrasives manufacturers are also contributing to the digital transformation of the manufacturing sector by integrating automation, data analytics, and digital tools into their production processes. These advancements are improving the quality and consistency of abrasives while reducing costs and waste.

As industries continue to evolve, abrasives manufacturers will play a key role in shaping the future of manufacturing by providing the tools and technologies needed to meet the demands of modern production.

Why Abrasives Manufacturers Matter in Today’s Market

Abrasives manufacturers are critical to the success of many industries, as their products are essential for a wide range of applications, from metalworking and construction to electronics and automotive manufacturing. Without abrasives, industries would not be able to achieve the precision, quality, and efficiency required in modern production processes.

Moreover, abrasives manufacturers are driving innovation in key sectors such as aerospace, automotive, and electronics by providing advanced materials and technologies that enable the production of cutting-edge products. These manufacturers are also helping industries reduce costs and improve sustainability by developing eco-friendly abrasives and adopting energy-efficient production processes.

In today’s highly competitive global market, abrasives manufacturers are essential partners for businesses looking to enhance their productivity, reduce their environmental impact, and stay ahead of the competition.

Best Practices for Leveraging Abrasives Manufacturers in Business

For businesses looking to capitalize on the growing abrasives market, there are several best practices to consider when working with abrasives manufacturers:

- Partner with Manufacturers Focused on Innovation: As industries demand more advanced materials and technologies, it is important to partner with abrasives manufacturers that prioritize innovation. Look for manufacturers that are investing in research and development and offering cutting-edge products like super abrasives and customized solutions.

- Prioritize Sustainability: With sustainability becoming increasingly important, businesses should prioritize working with abrasives manufacturers that focus on eco-friendly products and sustainable manufacturing practices. This can help improve your company’s environmental credentials and align with growing consumer demand for green products.

- Leverage Digital Tools: Digitalization is transforming the manufacturing industry, and businesses should take advantage of the digital tools offered by abrasives manufacturers. This includes utilizing data analytics, automated production processes, and virtual design tools to optimize your operations and improve product quality.

- Customize Solutions for Specific Applications: Industries are becoming more specialized, and there is growing demand for customized abrasive solutions. Work with abrasives manufacturers to develop products that meet the unique needs of your industry, whether it’s aerospace, electronics, or automotive manufacturing.

- Focus on Emerging Markets: The growth of emerging markets presents significant opportunities for businesses in the abrasives industry. Partner with abrasives manufacturers that have a strong presence in these regions and are well-positioned to capture market share in fast-growing industries like construction and manufacturing.

In conclusion, abrasives manufacturers play a vital role in driving innovation, sustainability, and efficiency across a wide range of industries. By staying informed about industry trends, focusing on advanced materials and technologies, and adopting best practices, businesses can leverage the expertise of abrasives manufacturers to succeed in a competitive global market. As demand for precision and eco-friendly solutions continues to grow, abrasives manufacturers will remain essential partners in the future of manufacturing.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices