-

Email Us

- Top Reports

The Evolution of Road Machinery: Trends, Insights, and Best Practices for Modern Infrastructure

Posted On 10 October, 2024

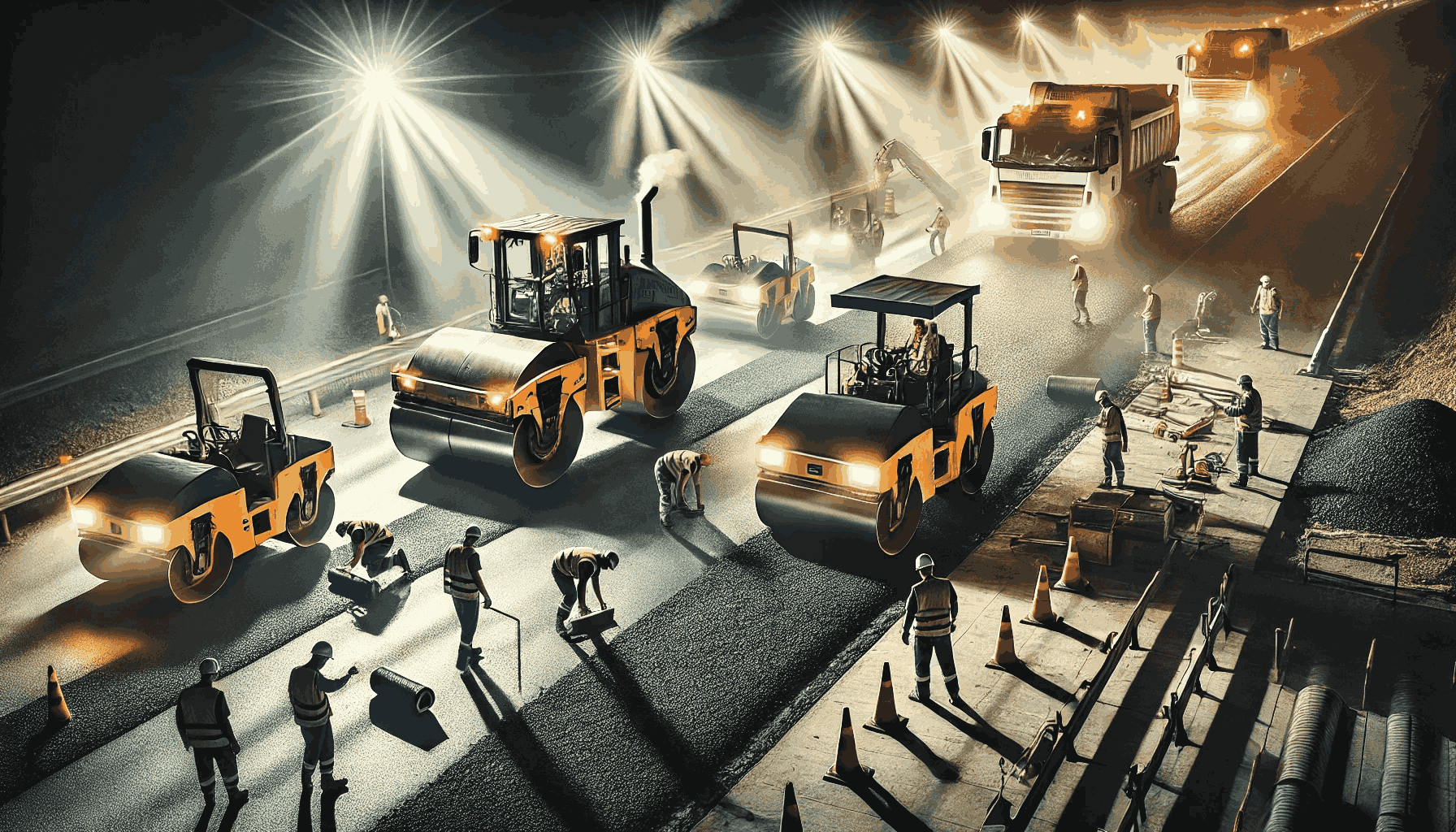

Road construction is one of the cornerstones of modern infrastructure development, connecting cities, facilitating trade, and improving access to essential services. At the heart of this crucial work lies road machinery, an industry that provides the tools and equipment necessary to build and maintain roads, highways, and bridges efficiently and effectively. In recent years, advances in technology, new trends in construction, and a growing focus on sustainability have transformed the road machinery industry. In this analysis, we will explore the latest trends shaping the industry, the key machinery used in road construction, and why road machinery is critical in today’s market. Additionally, we will provide best practices for businesses looking to leverage road machinery in their operations.

Road machinery encompasses a broad range of equipment, from heavy-duty machines like asphalt pavers and motor graders to smaller, specialized tools used for precise tasks. The goal of road machinery is to ensure that the construction and maintenance of roadways can be completed on time, on budget, and to the highest standards. As the demand for improved infrastructure continues to grow globally, the need for innovative, efficient, and reliable road machinery has never been greater.

Now Get Sample PDF Report on : Road Machinery Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=79052

Understanding the Different Types of Road Machinery

Before delving into the current trends, it’s important to understand the types of road machinery that are commonly used in construction projects. These machines are designed to perform specific functions, and they are often used in combination to achieve optimal results. Some of the most important types of road machinery include:

- Asphalt Pavers: Asphalt pavers are used to lay asphalt on roads, parking lots, and other surfaces. They are equipped with a hopper that receives the asphalt mixture, and a screed that spreads and compacts the material to create a smooth surface.

- Motor Graders: These machines are essential for leveling surfaces and preparing the ground before paving. Motor graders are equipped with a long blade that can be adjusted to create a flat, even surface.

- Excavators: Excavators are versatile machines used for digging, lifting, and moving earth. In road construction, they are often used for trenching, removing debris, and preparing the site.

- Rollers/Compactors: Compactors are critical for ensuring that the surface is properly compressed and stable. They are used to compact soil, gravel, and asphalt layers, making sure that the road surface is solid and durable.

- Concrete Mixers: For projects that involve the use of concrete, such as bridges or urban roads, concrete mixers are used to prepare and deliver the concrete to the construction site.

- Bulldozers: Bulldozers are used to move large quantities of soil or debris, clearing the way for other road construction activities.

- Dump Trucks: Dump trucks play a crucial role in transporting materials such as asphalt, gravel, and sand to and from the construction site.

Each of these machines plays a vital role in road construction, and advancements in technology are continually improving their efficiency, accuracy, and environmental impact.

Top 10 Trends in Road Machinery

The road machinery industry is evolving rapidly, driven by technological innovations, environmental considerations, and the increasing demand for modern infrastructure. Below are the top 10 trends currently shaping the industry:

- Automation and Robotics: The rise of automation is transforming road construction, with machinery now equipped with robotic features that enhance precision and efficiency. Automated pavers and graders can complete tasks with minimal human intervention, reducing errors and increasing speed.

- Telematics and Data Analytics: Telematics technology allows road machinery to be monitored in real-time, providing data on performance, fuel consumption, and machine health. This data-driven approach enables companies to optimize machine use, reduce downtime, and lower operational costs.

- Electric and Hybrid Machinery: As industries strive to reduce their carbon footprint, road machinery manufacturers are developing electric and hybrid machines. These machines offer the same level of performance as traditional equipment but with lower emissions and reduced fuel consumption.

- Sustainable Construction Materials: There is a growing emphasis on using sustainable materials in road construction, including recycled asphalt and environmentally friendly additives. Road machinery is being adapted to work with these new materials, ensuring that roads are built with sustainability in mind.

- 3D Machine Control: 3D machine control systems are revolutionizing how road machinery is operated. By using GPS and laser technology, these systems allow operators to work with greater precision, ensuring that roads are built to exact specifications.

- Self-Healing Materials: Innovations in materials science have led to the development of self-healing asphalt and concrete. These materials can repair minor cracks and damages automatically, reducing the need for frequent maintenance. Machinery is being adapted to work with these materials, extending the lifespan of roads.

- Compact and Multi-Functional Machinery: As urban spaces become more congested, there is a growing demand for compact road machinery that can work in tight spaces. Multi-functional machines that can perform several tasks, such as digging, grading, and compacting, are becoming increasingly popular.

- Artificial Intelligence (AI) Integration: AI is being integrated into road machinery to enhance decision-making and improve efficiency. For example, AI-powered sensors can adjust machinery settings based on the specific conditions of the construction site, optimizing performance.

- Sustainability Reporting: With the increasing focus on sustainability, construction companies are now required to track and report their environmental impact. Telematics and data analytics in road machinery provide detailed insights into fuel consumption, emissions, and other environmental factors, helping companies stay compliant with regulations.

- Predictive Maintenance: Predictive maintenance technology uses data from telematics and sensors to predict when a machine is likely to fail. This allows companies to perform maintenance before a breakdown occurs, reducing downtime and increasing productivity.

How Road Machinery is Changing the Industry

The trends mentioned above are not only shaping the road machinery industry but also transforming the entire construction sector. Automation, AI, and data analytics are making road construction faster, more accurate, and less labor-intensive. These technologies enable construction companies to complete projects with fewer workers while maintaining high levels of precision.

Moreover, the integration of sustainable practices into road machinery is helping the construction industry reduce its environmental impact. Electric and hybrid machines are reducing emissions, while recycled materials and self-healing asphalt are cutting down on waste. This shift towards sustainability is not only good for the environment but also beneficial for companies that want to meet the growing demand for eco-friendly infrastructure projects.

The adoption of telematics and predictive maintenance is also changing the way companies manage their fleets of road machinery. Instead of reacting to breakdowns, companies can now take a proactive approach to maintenance, reducing costly downtime and ensuring that projects stay on schedule. This data-driven approach to machinery management is improving efficiency and reducing operational costs across the board.

Why Road Machinery Matters in Today’s Market

The importance of road machinery cannot be overstated in today's global economy. Roads are the lifelines that connect communities, businesses, and industries, making the efficient construction and maintenance of roads a top priority for governments and private sector entities alike. Without the right machinery, building and maintaining this infrastructure would be nearly impossible.

In addition to its role in supporting infrastructure development, road machinery is critical for ensuring the safety and durability of roads. Well-built roads reduce the likelihood of accidents, improve fuel efficiency for vehicles, and lower maintenance costs over time. High-quality machinery is essential for achieving these outcomes, as it ensures that roads are constructed to withstand heavy traffic and environmental conditions.

Furthermore, as urbanization continues to accelerate, the demand for road construction and maintenance is only set to grow. Emerging economies are investing heavily in infrastructure to support economic development, while developed countries are focused on upgrading aging road networks. In this context, road machinery is a key driver of economic growth and social progress.

Best Practices for Leveraging Road Machinery in Business

For construction companies and contractors, leveraging road machinery effectively is essential for delivering successful projects on time and within budget. Below are some best practices to help businesses get the most out of their road machinery:

- Invest in the Latest Technology: Staying up-to-date with the latest advancements in road machinery can significantly improve efficiency and reduce costs. Investing in machines equipped with automation, telematics, and AI can help your company work more effectively and stay competitive in the industry.

- Focus on Sustainability: As environmental regulations become stricter, using road machinery that supports sustainable construction practices is crucial. Look for equipment that is designed to reduce emissions and work with eco-friendly materials, helping your business meet regulatory requirements and appeal to eco-conscious clients.

- Prioritize Maintenance: Implementing a predictive maintenance program can help prevent costly breakdowns and extend the lifespan of your road machinery. Use telematics and data analytics to monitor machine health and address issues before they lead to downtime.

- Train Your Operators: Proper training is essential for getting the most out of your road machinery. Ensure that your operators are familiar with the latest technology and best practices for using the equipment. Regular training can also help reduce accidents and improve the overall quality of your work.

- Optimize Fleet Management: Efficient fleet management is key to ensuring that your road machinery is used effectively. Use telematics to track machine usage, fuel consumption, and maintenance needs, allowing you to make informed decisions about when to deploy or retire equipment.

- Choose the Right Machinery for the Job: Not all road machinery is created equal, and selecting the right equipment for each project is essential. Consider the size and scope of the project, the materials being used, and the specific conditions of the construction site when choosing machinery.

The road machinery industry is undergoing significant changes, driven by advancements in technology, sustainability, and the increasing demand for infrastructure development. These trends are not only improving the efficiency and precision of road construction but also helping the industry reduce its environmental impact. For businesses involved in road construction, staying ahead of these trends and adopting best practices for managing road machinery is crucial for success in today’s competitive market.

By investing in the latest machinery, embracing sustainability, and leveraging data-driven insights, companies can optimize their operations, reduce costs, and deliver high-quality infrastructure projects that meet the needs of modern societies. Road machinery will continue to play a vital role in shaping the future of transportation, and businesses that adapt to the evolving industry will be well-positioned for long-term growth and success.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices