-

Email Us

- Top Reports

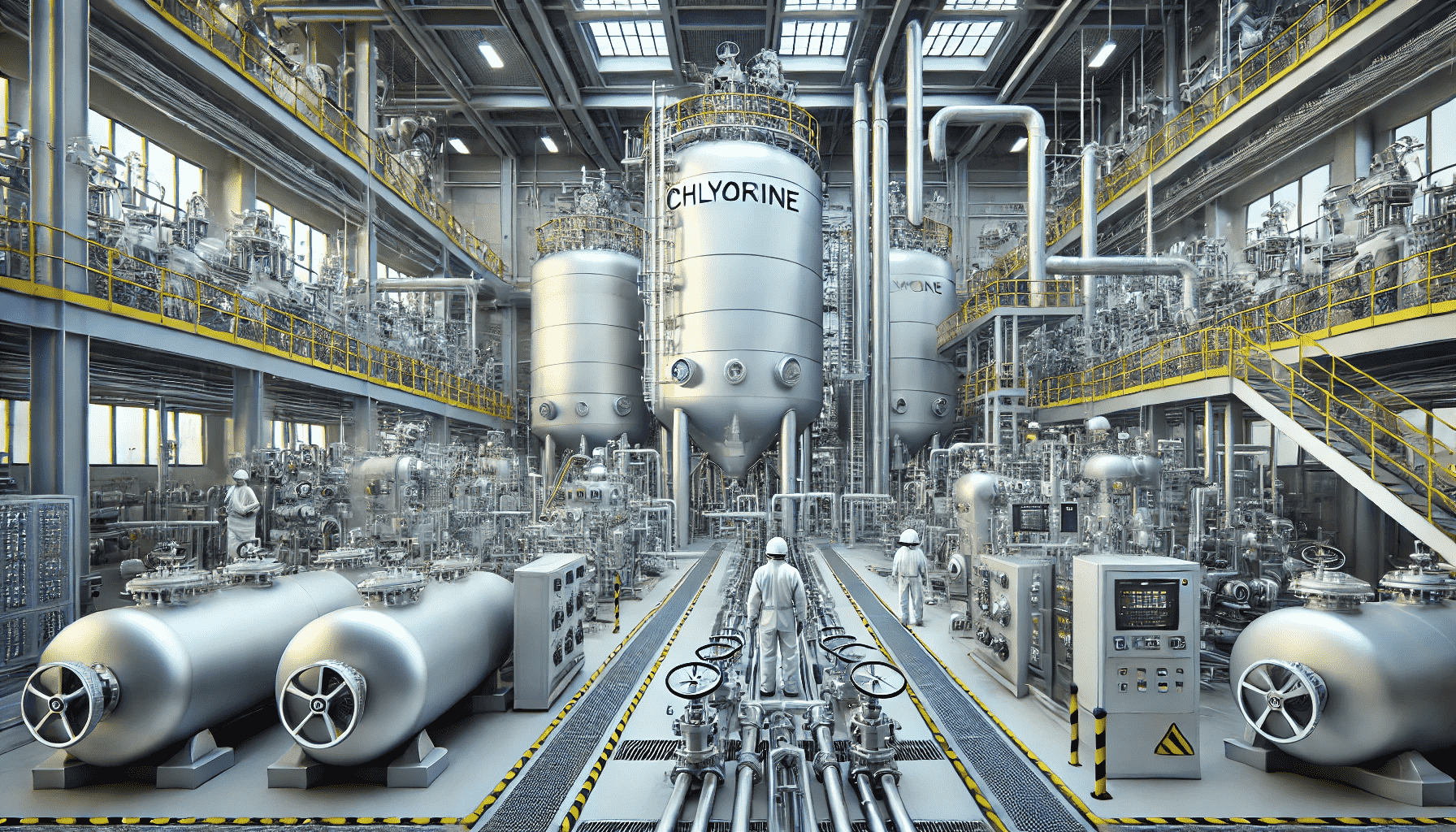

A Comprehensive Analysis of Chlorine Manufacturers: Key Trends, Market Impact, and Best Practices

Posted On 09 October, 2024

Chlorine is a chemical that plays a critical role in various industries, from water purification and sanitation to the production of plastics, chemicals, and pharmaceuticals. Its versatility and wide range of applications make it an essential material in both industrial and commercial sectors. Chlorine manufacturers are the backbone of this supply chain, providing the chemical in large quantities to meet global demand. The chlorine manufacturing industry is constantly evolving, influenced by new technologies, environmental concerns, and shifting market dynamics.

In this analysis, we will provide a detailed look into the chlorine manufacturing industry, highlighting key trends, how the sector is transforming, and best practices for businesses that rely on chlorine in their operations.

Now Get Sample PDF Report on : Chlorine (Cl2) Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=140022

Top 10 Trends in Chlorine Manufacturers

As the global demand for chlorine continues to grow, several trends are shaping the industry and influencing how chlorine manufacturers operate. These trends reflect technological advancements, environmental considerations, and economic factors that are driving change in the sector.

1. Increased Focus on Sustainability and Environmental Impact

Sustainability is a key trend in the chlorine manufacturing industry as governments and businesses push for more eco-friendly production methods. Chlorine manufacturing has historically been energy-intensive, with significant environmental concerns related to emissions and waste. As a result, manufacturers are investing in cleaner technologies, such as membrane cell technology, which uses less energy and reduces harmful emissions compared to traditional methods like mercury-based processes.

Chlorine manufacturers are also working to improve waste management practices and reduce their overall carbon footprint, aligning with global sustainability goals.

2. Advancements in Chlor-Alkali Process Efficiency

The chlor-alkali process, which produces both chlorine and caustic soda, is the primary method of chlorine production. Recent advancements in this process have improved energy efficiency, reducing production costs and environmental impact. Innovations in electrolyzers and power management systems are enabling manufacturers to increase the efficiency of chlorine production, making the process more sustainable and cost-effective.

These improvements are helping manufacturers meet the growing demand for chlorine while adhering to stricter environmental regulations.

3. Growing Demand from the Water Treatment Industry

One of the largest applications of chlorine is in water treatment, where it is used to disinfect drinking water and treat wastewater. The global demand for clean and safe water continues to rise, particularly in developing regions where access to clean water is limited. Chlorine manufacturers are seeing increased demand from municipalities, industries, and governments for water treatment solutions that use chlorine.

The growth of urbanization and industrialization has also led to a rise in wastewater production, driving the need for more effective disinfection methods, which further boosts chlorine demand.

4. Shift Toward On-Site Chlorine Generation

On-site chlorine generation, where chlorine is produced and used directly at the location where it is needed, is becoming increasingly popular. This method eliminates the need for transporting chlorine, reducing logistics costs and improving safety. On-site chlorine generation systems are particularly useful in water treatment facilities and industrial plants where large quantities of chlorine are required on a continuous basis.

This trend is driven by safety concerns associated with transporting chlorine over long distances, as well as the desire for greater operational efficiency.

5. Expansion of Chlorine Derivatives Market

Chlorine is not only used as a standalone chemical but also as a key raw material for producing a wide range of chlorine derivatives. These include polyvinyl chloride (PVC), hydrochloric acid, chlorinated solvents, and refrigerants. The global market for chlorine derivatives is expanding, with growing demand from industries such as construction, automotive, and electronics.

PVC, in particular, is one of the most widely produced chlorine derivatives and is used in building materials, piping, and medical devices, making it a significant driver of chlorine demand.

6. Regulatory Pressures and Compliance

Chlorine manufacturers face increasing regulatory pressures to comply with environmental, health, and safety standards. Governments around the world are implementing stricter regulations on emissions, waste disposal, and chemical safety, particularly in developed regions like North America and Europe. Compliance with these regulations is critical for manufacturers to continue operating and avoid costly fines or shutdowns.

Chlorine manufacturers are investing in technologies and practices that improve their compliance with these regulations, ensuring that their operations meet global safety and environmental standards.

7. Growing Importance of Chlorine in Pharmaceutical Manufacturing

The pharmaceutical industry relies heavily on chlorine and its derivatives in the production of active pharmaceutical ingredients (APIs) and intermediates. Chlorine is used in a variety of reactions and processes to create life-saving medications and treatments. As the pharmaceutical industry continues to grow, particularly in light of the COVID-19 pandemic, the demand for chlorine from pharmaceutical manufacturers is increasing.

Chlorine manufacturers are expanding their production capacity to meet the needs of the pharmaceutical sector, which has become a key growth driver for the industry.

8. Globalization of the Chlorine Market

The chlorine market is becoming increasingly globalized, with manufacturers expanding their operations to meet demand in emerging markets. Countries in Asia-Pacific, Latin America, and the Middle East are seeing significant growth in chlorine consumption due to industrialization and infrastructure development. This has led to increased investment in chlorine production facilities in these regions, allowing manufacturers to better serve local markets and reduce transportation costs.

Global trade agreements and improved logistics are also enabling chlorine manufacturers to export their products more easily, further expanding their market reach.

9. Safety Innovations in Chlorine Handling and Transport

Safety is a top priority in the chlorine manufacturing industry, particularly when it comes to handling and transporting the chemical. Chlorine is a hazardous material, and improper handling can lead to accidents, leaks, and environmental damage. To mitigate these risks, manufacturers are adopting new safety technologies and protocols to improve the safe transport and storage of chlorine.

Innovations such as advanced leak detection systems, automated handling equipment, and improved packaging materials are helping to reduce the risk of accidents and ensure the safe delivery of chlorine to end users.

10. Circular Economy and Waste Minimization

As part of the broader push for sustainability, chlorine manufacturers are exploring ways to minimize waste and adopt circular economy practices. This involves reusing and recycling chlorine and its by-products to reduce the amount of waste generated during production. For example, chlorine manufacturers are finding ways to repurpose waste brine generated during the chlor-alkali process, reducing the need for raw materials and minimizing environmental impact.

By implementing circular economy practices, chlorine manufacturers can reduce their environmental footprint and create new revenue streams from recycled materials.

How Chlorine Manufacturers are Changing the Industry

Chlorine manufacturers are at the forefront of change in industries such as water treatment, pharmaceuticals, construction, and more. As they adopt new technologies and processes, they are driving innovation across these sectors. The shift toward more sustainable production methods is helping to reduce the environmental impact of chlorine manufacturing, making it a cleaner and more efficient industry.

Chlorine manufacturers are also playing a key role in addressing global challenges such as water scarcity and public health. By providing the chemicals needed for water disinfection and pharmaceutical production, they are contributing to improving the quality of life for millions of people worldwide.

The expansion of the chlorine derivatives market, particularly in the production of PVC and other industrial chemicals, is further boosting demand for chlorine. This is leading to increased investment in new production facilities and the development of more advanced technologies for chlorine manufacturing.

Why Chlorine Manufacturers Matter in Today’s Market

Chlorine manufacturers are essential to the global economy because chlorine is a fundamental component in a wide range of industries. From ensuring clean drinking water and wastewater treatment to producing pharmaceuticals, plastics, and chemicals, chlorine is a vital resource that underpins many critical sectors. Without a reliable supply of chlorine, these industries would struggle to meet demand and maintain operations.

In today’s market, where sustainability and environmental responsibility are top priorities, chlorine manufacturers are working to meet the growing demand for greener production methods. By investing in cleaner technologies and reducing their environmental impact, they are helping to ensure that chlorine production remains viable in a world that is increasingly focused on reducing carbon emissions.

Best Practices for Leveraging Chlorine Manufacturers in Business

For businesses that rely on chlorine for their operations, building strong relationships with chlorine manufacturers is essential for ensuring a consistent and reliable supply of the chemical. Here are some best practices for leveraging chlorine manufacturers in business:

- Focus on Sustainability: Partner with chlorine manufacturers that prioritize sustainability and invest in green technologies. This will help reduce your environmental footprint and ensure compliance with regulatory requirements.

- Choose Reliable Suppliers: Look for manufacturers with a proven track record of reliability and safety. This is especially important when dealing with hazardous chemicals like chlorine, where the risks of leaks and accidents can have serious consequences.

- Invest in On-Site Generation: For businesses that use large quantities of chlorine, investing in on-site chlorine generation systems can reduce transportation costs and improve operational efficiency. This method also enhances safety by eliminating the need to transport chlorine over long distances.

- Stay Compliant with Regulations: Work closely with chlorine manufacturers to ensure that your business complies with environmental, health, and safety regulations. Manufacturers that invest in compliance technologies and practices will be valuable partners in maintaining regulatory compliance.

- Plan for Market Fluctuations: The chlorine market can be affected by fluctuations in demand and supply chain disruptions. Build contingency plans with your suppliers to ensure that you have access to the chlorine you need, even during periods of market volatility.

In conclusion, chlorine manufacturers are a vital part of the global economy, providing the chemicals necessary for a wide range of industries. By staying informed about industry trends, focusing on sustainability, and working with reliable suppliers, businesses can effectively leverage the expertise of chlorine manufacturers to drive growth and remain competitive in today’s market.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices