-

Email Us

- Top Reports

A Comprehensive Analysis of CFRP: Trends, Industry Insights, and Best Practices

Posted On 09 October, 2024

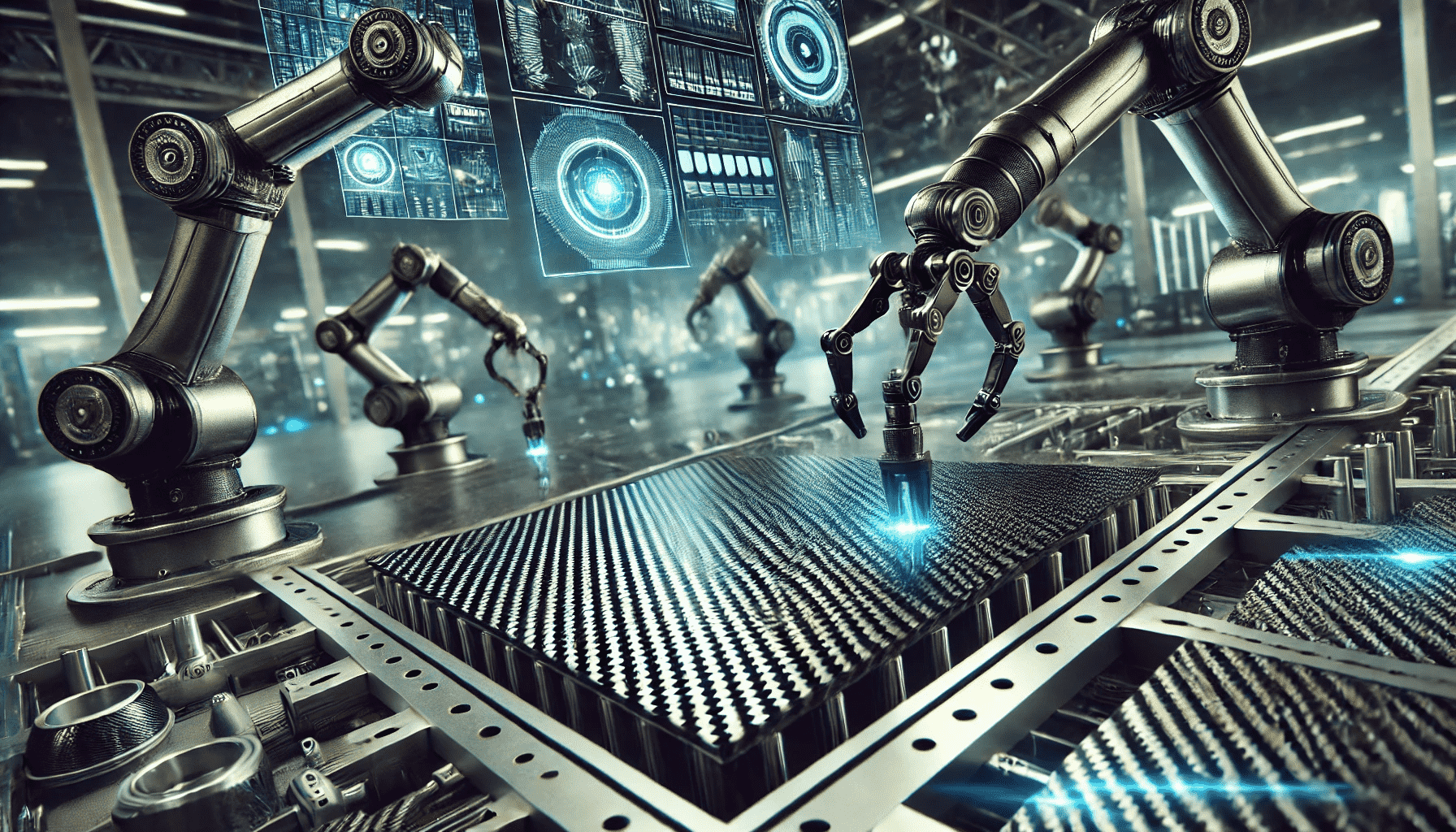

Carbon Fiber Reinforced Polymer (CFRP) has emerged as one of the most versatile and sought-after materials in industries ranging from aerospace and automotive to construction and sports equipment. Known for its exceptional strength-to-weight ratio, durability, and resistance to corrosion, CFRP is playing a critical role in transforming how products are designed and manufactured. Whether it’s reducing the weight of aircraft to improve fuel efficiency or enhancing the performance of high-end sports equipment, CFRP is changing the landscape of material science.

In this analysis, we will explore the latest trends shaping the CFRP industry, provide insights into how CFRP is impacting various sectors, and discuss why this advanced material is essential in today’s market. Additionally, we will share best practices for businesses looking to leverage CFRP in their operations.

Now Get Sample PDF Report on : CFRP Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=224478

Top 10 Trends in CFRP

The use of CFRP is growing across multiple industries as advancements in production and material science make this composite more accessible and affordable. Here are the top 10 trends currently shaping the CFRP industry:

1. Increased Use in Automotive Lightweighting

One of the most significant trends in the CFRP industry is its increasing use in automotive lightweighting. With growing pressure on car manufacturers to improve fuel efficiency and reduce carbon emissions, the need for lighter materials has become paramount. CFRP offers a solution by providing the strength of steel at a fraction of the weight. As a result, automotive companies are integrating CFRP into body panels, structural components, and even entire vehicle frames.

This trend is expected to continue as electric vehicles (EVs) gain traction, with CFRP playing a key role in extending battery range by reducing vehicle weight.

2. Growth of CFRP in Aerospace Applications

Aerospace is one of the earliest adopters of CFRP, and its use in the industry continues to grow. Commercial aircraft manufacturers, such as Boeing and Airbus, use CFRP to build lightweight, fuel-efficient aircraft that offer superior strength and corrosion resistance. The Boeing 787 Dreamliner, for example, is composed of approximately 50% CFRP by weight, contributing to significant fuel savings and operational efficiency.

The demand for more sustainable aviation solutions is pushing the aerospace industry to further explore the use of CFRP in future aircraft designs, including hybrid and electric planes.

3. Expansion in Wind Energy

CFRP is gaining ground in the renewable energy sector, particularly in wind energy. As wind turbine blades become larger to capture more energy, manufacturers are turning to CFRP to create longer, more efficient blades that can withstand the high mechanical loads experienced during operation. CFRP’s lightweight nature allows for longer blades without compromising strength or performance, resulting in higher energy output.

This trend is part of the larger push to decarbonize the energy sector and increase the use of renewable energy sources globally.

4. Advancements in CFRP Recycling

While CFRP is known for its durability and long lifespan, its recycling has historically been a challenge due to the complexity of separating carbon fibers from the polymer matrix. However, recent advancements in CFRP recycling technologies are addressing this issue, allowing manufacturers to recover and reuse carbon fibers in new applications. This development is driving sustainability in the CFRP industry, as companies can reduce waste and minimize the environmental impact of their products.

The rise of recycled CFRP is not only contributing to a circular economy but also making the material more cost-effective for manufacturers.

5. Development of High-Volume Manufacturing Techniques

CFRP has traditionally been associated with high-performance, low-volume industries like aerospace and motorsports. However, recent developments in high-volume manufacturing techniques, such as automated layup processes and resin transfer molding, are making CFRP more accessible for mass-market applications. These advancements are reducing production costs and cycle times, making it easier for manufacturers to integrate CFRP into consumer products such as bicycles, sporting goods, and automotive components.

As production costs continue to decrease, the use of CFRP is expected to expand across a wider range of industries.

6. Integration into Construction and Infrastructure

The construction industry is also recognizing the benefits of CFRP for structural reinforcement and building materials. CFRP is being used in bridges, buildings, and other infrastructure projects to strengthen concrete, steel, and masonry structures. Its high strength and resistance to corrosion make it an ideal material for retrofitting aging infrastructure, where it can extend the lifespan of structures and reduce maintenance costs.

This trend highlights the versatility of CFRP as it finds applications beyond traditional sectors, helping to improve the resilience and sustainability of infrastructure.

7. Customization and 3D Printing

The rise of 3D printing technologies is transforming how CFRP is used in manufacturing. 3D printing allows for the production of customized CFRP components with complex geometries that would be difficult to achieve with traditional manufacturing methods. This is especially useful in industries like aerospace, automotive, and medical devices, where precision and customization are critical.

As 3D printing technology continues to evolve, we can expect to see more widespread adoption of CFRP in highly specialized and customized applications.

8. Enhanced Performance in Sports Equipment

CFRP is widely used in high-performance sports equipment such as bicycles, tennis rackets, and golf clubs. The lightweight and durable nature of CFRP allows athletes to perform at their best, with equipment that maximizes strength and minimizes weight. This trend is particularly prevalent in professional sports, where every advantage matters, and manufacturers are constantly looking for ways to improve their products.

As technology improves, we can expect CFRP to play an even bigger role in developing innovative sports equipment that offers superior performance.

9. Electrification and Energy Storage Solutions

As the world shifts towards renewable energy and electrification, CFRP is playing an important role in energy storage solutions. In addition to its use in wind turbines, CFRP is being explored for battery housings in electric vehicles and energy storage systems. The material’s lightweight properties help reduce the overall weight of these systems, improving energy efficiency and performance.

CFRP’s potential for thermal conductivity and durability makes it an attractive option for future energy storage innovations.

10. Sustainability and Lifecycle Analysis

With increased awareness of environmental impact, businesses are paying closer attention to the sustainability of materials like CFRP. Lifecycle analysis is becoming an essential aspect of CFRP production, with manufacturers considering the environmental cost from raw material extraction to end-of-life disposal or recycling. Sustainable production processes, coupled with advancements in recycling, are positioning CFRP as a more eco-friendly option in industries focused on reducing their carbon footprint.

This trend aligns with broader global efforts to improve sustainability in manufacturing and promote responsible use of resources.

How CFRP is Changing the Industry

CFRP is fundamentally changing multiple industries by offering a combination of strength, flexibility, and lightweight properties that traditional materials like steel or aluminum cannot match. In the aerospace sector, the use of CFRP has revolutionized aircraft design, allowing manufacturers to build lighter, more fuel-efficient planes. This innovation has led to significant reductions in carbon emissions and operational costs for airlines, contributing to a more sustainable aviation industry.

Similarly, in the automotive industry, CFRP’s role in lightweighting has been crucial in the development of electric vehicles. Reducing the weight of the vehicle helps increase the driving range, which is a critical factor for consumers considering electric cars. The adoption of CFRP in automotive production is helping manufacturers meet stringent emissions regulations while delivering high-performance vehicles.

In construction and infrastructure, CFRP is enabling engineers to create stronger, more durable structures that require less maintenance and offer longer service lives. Its corrosion-resistant properties make it ideal for reinforcing bridges, tunnels, and other critical infrastructure, particularly in environments exposed to harsh weather conditions.

Beyond traditional sectors, CFRP is also changing the sports equipment industry by providing athletes with lighter, stronger gear that enhances their performance. Whether it’s a racing bike, a tennis racket, or a pair of running shoes, CFRP is enabling athletes to push the boundaries of their capabilities.

Why CFRP Matters in Today’s Market

CFRP is critical in today’s market for several reasons. First, it addresses the growing demand for materials that can improve performance while reducing environmental impact. As industries work to meet sustainability goals, CFRP offers a solution that allows companies to reduce the weight of products, improve fuel efficiency, and cut carbon emissions.

Second, CFRP’s versatility makes it an attractive option for a wide range of applications, from aerospace and automotive to consumer goods and renewable energy. Its ability to withstand high loads, resist corrosion, and provide long-term durability makes it a valuable material for industries looking to enhance the lifespan and performance of their products.

Finally, CFRP is paving the way for new manufacturing techniques, such as high-volume production and 3D printing, that are expanding its use in mass-market products. This scalability is essential as more companies look to integrate CFRP into their operations to remain competitive and innovative.

Best Practices for Leveraging CFRP in Business

For businesses looking to integrate CFRP into their operations, there are several best practices to consider:

- Collaborate with Experienced Suppliers: Partner with suppliers and manufacturers that have expertise in CFRP production. This ensures that your products benefit from high-quality materials and the latest advancements in CFRP technology.

- Invest in High-Volume Manufacturing: To reduce costs and increase scalability, businesses should explore high-volume manufacturing techniques such as automated layup processes and resin transfer molding. These methods can streamline production and make CFRP more accessible for mass-market applications.

- Prioritize Sustainability: Incorporating sustainable practices into your use of CFRP, such as investing in recycled materials and reducing waste, can enhance your company’s reputation as an environmentally conscious brand.

- Leverage 3D Printing for Customization: For industries that require precision and customization, 3D printing with CFRP offers the ability to create complex components that are tailored to specific applications.

- Stay Informed on Advancements: The CFRP industry is constantly evolving, with new technologies and materials being developed. Staying informed about the latest trends and innovations will allow your business to take full advantage of the benefits CFRP has to offer.

In conclusion, CFRP is transforming industries by offering unmatched strength, durability, and lightweight properties. From aerospace and automotive to sports equipment and construction, CFRP is driving innovation and creating new opportunities for businesses. By staying ahead of industry trends, investing in advanced manufacturing techniques, and prioritizing sustainability, companies can leverage CFRP to enhance their products and gain a competitive edge in today’s market.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices