-

Email Us

- Top Reports

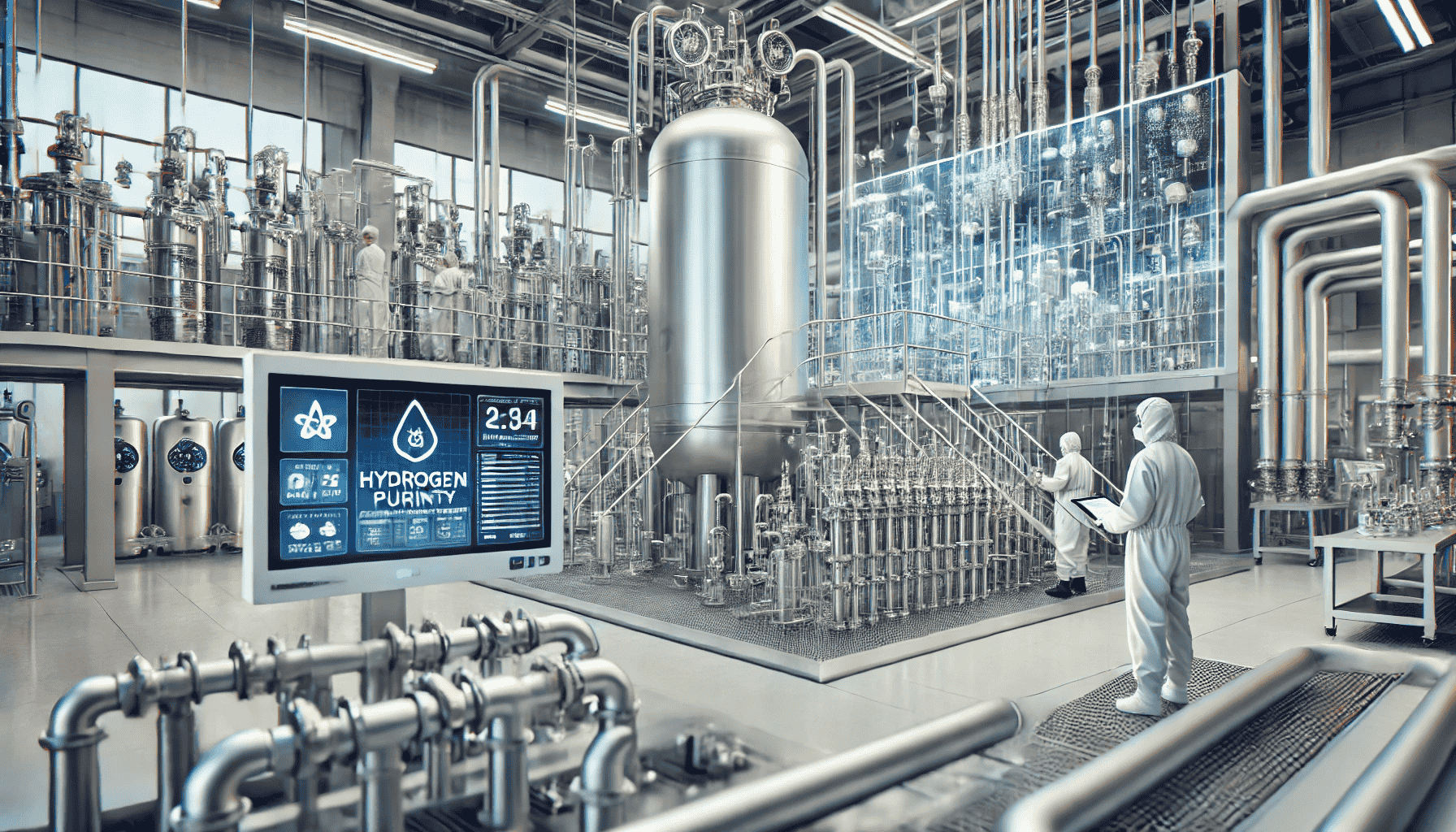

Top 10 Trends in Hydrogen Purifiers: Innovations, Applications, and Future Prospects

Posted On 15 November, 2024

Hydrogen purification has become a critical component in industries that rely on pure hydrogen for operations. With hydrogen emerging as a sustainable fuel source and a key player in green energy, the demand for effective hydrogen purifiers is on the rise. These devices remove contaminants, ensuring high-purity hydrogen for applications in fuel cells, laboratories, and industrial processes. This blog explores the top trends in hydrogen purifiers, covering advancements, industry applications, and the growing importance of hydrogen purification in today’s market. By understanding these trends, businesses can make informed decisions, improve efficiency, and support sustainable energy efforts.

Now Get Sample PDF Report on : Hydrogen Purifier Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=193706

1. Advanced Membrane Technologies for Enhanced Purification

Membrane technology has significantly advanced in recent years, providing more efficient hydrogen purification methods. Proton exchange membranes (PEMs) and palladium-based membranes are two types that have gained popularity due to their high selectivity and permeability. These membranes work by allowing hydrogen molecules to pass through while blocking contaminants such as nitrogen, oxygen, and carbon monoxide. For instance, palladium-based membranes are particularly effective in separating hydrogen from mixed gases, commonly used in industrial and research settings where high-purity hydrogen is essential. By using advanced materials and nano-coatings, these membranes improve the efficiency and lifespan of purifiers, reducing the frequency of replacements and maintenance.

High-purity hydrogen is critical for applications in fuel cells, chemical synthesis, and semiconductor manufacturing. Advanced membrane technologies provide efficient and cost-effective purification solutions, enabling companies to produce hydrogen that meets strict purity requirements. For businesses, adopting membrane-based purification technologies means less downtime and lower maintenance costs, leading to increased productivity and cost savings. Moreover, as industries move towards green hydrogen, having reliable purification systems will be essential to meet sustainability goals and support the broader adoption of hydrogen as a clean energy source.

Companies seeking to improve hydrogen purity should consider investing in purifiers with advanced membrane technology. Evaluating the specific needs of each application, such as the required purity levels and operating temperatures, can help businesses choose the right type of membrane. Partnering with reputable suppliers and staying informed about advancements in membrane materials can ensure that businesses receive durable, efficient, and high-performing hydrogen purifiers.

2. Integration of AI and IoT for Real-Time Monitoring

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into hydrogen purifiers allows for real-time monitoring and control of purification processes. IoT sensors can detect impurities, temperature, pressure, and other critical variables, while AI algorithms analyze this data to optimize performance and predict maintenance needs. Companies like Air Liquide and Linde have started implementing IoT-enabled purifiers that send alerts to operators when filters need replacement or adjustments are required. For example, an IoT-enabled purifier in a fuel cell station can automatically adjust its filtration process to ensure consistent purity, while also notifying technicians if maintenance is needed.

Real-time monitoring enhances the reliability and efficiency of hydrogen purifiers by ensuring that they operate within optimal parameters at all times. For businesses, this means fewer disruptions, reduced maintenance costs, and longer equipment lifespans. AI-driven insights also enable proactive maintenance, minimizing the risk of unexpected downtimes and enhancing safety. Additionally, the data collected can inform future improvements, helping companies optimize hydrogen purification processes and reduce operational costs.

Businesses should explore IoT-enabled hydrogen purifiers that offer remote monitoring and data analytics capabilities. Working with technology providers who specialize in industrial IoT can help companies integrate these advanced features effectively. Ensuring proper data security and training staff to interpret and act on AI-driven insights will also maximize the benefits of this technology, improving the overall efficiency and reliability of hydrogen purification systems.

3. Compact and Modular Designs for Flexibility

The demand for hydrogen purifiers with compact and modular designs has grown, particularly in sectors with space constraints or varying purification needs. Modular purifiers can be scaled up or down based on the required hydrogen output, making them versatile for different applications. For instance, smaller, portable hydrogen purifiers are being used in mobile fuel cell applications, while modular systems are popular in research facilities where purification needs may fluctuate. Companies like Parker Hannifin and Mitsubishi have introduced compact, modular hydrogen purifiers that can be easily installed in laboratories, small-scale production units, or fuel cell stations without requiring extensive infrastructure modifications.

Compact and modular designs offer flexibility for industries with diverse or changing hydrogen requirements. For businesses, adopting modular purifiers can improve operational efficiency, as these systems can be adapted to meet production demands without the need for costly upgrades. The reduced footprint of compact purifiers also makes them ideal for small facilities or mobile applications, enabling businesses to access high-purity hydrogen even in constrained spaces. Furthermore, modular systems are often more energy-efficient, helping companies reduce their overall environmental impact.

Companies should assess their hydrogen needs and consider whether a modular or compact purifier could meet their requirements. Consulting with suppliers who offer customizable systems can help ensure the chosen purifier matches both current and future needs. Additionally, maintaining flexibility in purification capacity can enable businesses to adapt quickly to industry changes, supporting both scalability and cost-effectiveness.

4. Demand for High-Purity Hydrogen in Fuel Cell Technology

Fuel cell technology relies on high-purity hydrogen to function efficiently, as impurities can reduce the cell’s lifespan and performance. Hydrogen purifiers are essential in fuel cell applications, where even trace contaminants can have significant effects. For instance, automotive companies like Toyota and Hyundai, which produce hydrogen fuel cell vehicles, use high-grade hydrogen purifiers to ensure that the hydrogen powering their vehicles is free from contaminants. These purifiers maintain the purity levels necessary for optimal fuel cell function, supporting the vehicle’s longevity and performance.

The growth of fuel cell technology in transportation and stationary power applications underscores the need for effective hydrogen purification. High-purity hydrogen ensures that fuel cells operate efficiently, reducing wear and prolonging equipment life. For businesses in the fuel cell market, investing in robust hydrogen purifiers translates into better product performance and a competitive edge in the emerging hydrogen economy. As governments worldwide push for cleaner transportation, high-quality hydrogen purification systems are essential for meeting regulatory standards and achieving sustainability goals.

Companies involved in fuel cell production should prioritize hydrogen purifiers that can achieve the necessary purity levels for fuel cell applications. Collaborating with purification technology providers can help companies stay updated on advancements in fuel cell-compatible purifiers. Implementing rigorous maintenance protocols to prevent contamination and maximize fuel cell efficiency will further support product performance and longevity.

5. Regenerative Purification Systems for Cost Efficiency

Regenerative purification systems are designed to reduce costs and waste by allowing purifiers to regenerate and reuse purification materials. For example, PSA (Pressure Swing Adsorption) systems and palladium membranes can be regenerated, allowing them to operate efficiently over extended periods without the need for frequent replacement. Companies that utilize regenerative purifiers, such as chemical plants and laboratories, benefit from continuous hydrogen purification with lower operational costs. These systems provide an economical solution for industries that require high-purity hydrogen but face budget constraints or prefer long-term solutions.

Regenerative systems enhance cost-efficiency by minimizing the need for new purification materials and reducing downtime associated with maintenance. For businesses, this means lower operational expenses and a more sustainable approach to hydrogen purification. Regenerative purifiers also contribute to a reduction in waste, which aligns with growing corporate responsibility toward sustainability. Industries that rely on large volumes of hydrogen, such as electronics and pharmaceuticals, find regenerative systems particularly valuable, as they ensure a steady supply of pure hydrogen without frequent interruptions.

Businesses seeking cost-effective purification solutions should explore regenerative systems that allow materials to be reused. Working with suppliers who specialize in regenerative technology can help companies implement systems that match their hydrogen usage patterns. Regular monitoring and maintenance are essential to maximize the lifespan of regenerative systems, further optimizing cost savings and supporting sustainability initiatives.

6. Increased Demand for Hydrogen Purification in Semiconductor Manufacturing

The semiconductor industry requires ultra-high-purity hydrogen for processes such as wafer cleaning and chemical vapor deposition. Impurities in hydrogen can lead to defects in semiconductor products, making purification a critical step in the manufacturing process. Companies like Intel and Samsung use specialized hydrogen purifiers capable of removing even trace contaminants to meet the stringent purity requirements of semiconductor fabrication. These purification systems are designed to achieve purity levels that prevent contamination and support the production of high-quality semiconductors, which are essential for a wide range of electronics.

The semiconductor industry’s need for ultra-pure hydrogen drives demand for advanced purification solutions. For businesses in semiconductor manufacturing, reliable purification is essential to maintain product quality and meet the high standards of this industry. High-purity hydrogen ensures that semiconductor production processes are free from contaminants, reducing defect rates and maximizing yield. As the demand for semiconductors grows, the need for efficient and effective hydrogen purification systems will also increase, underscoring the importance of investing in high-quality purifiers.

Semiconductor manufacturers should partner with purification providers who understand the specific purity requirements of the industry. Regular testing and calibration of purification systems are crucial to ensure consistent purity. By maintaining strict quality control in hydrogen purification, semiconductor companies can minimize defects, optimize production efficiency, and strengthen their reputation for high-quality products.

7. Green Hydrogen Production and Purification

As the world shifts towards renewable energy, green hydrogen, produced through water electrolysis powered by renewable sources, has gained popularity. However, even green hydrogen requires purification to remove residual impurities before it can be used in sensitive applications. Companies like Siemens and ITM Power produce hydrogen purifiers that are compatible with green hydrogen production processes, ensuring that the final hydrogen product meets industry purity standards. Green hydrogen is increasingly used in fuel cells, industrial applications, and as an alternative energy source, making purification an essential part of the green hydrogen supply chain.

Green hydrogen offers a sustainable alternative to traditional hydrogen production methods, but its effectiveness depends on reliable purification processes. For businesses, investing in purification systems that support green hydrogen production not only aligns with environmental goals but also positions them as leaders in the clean energy market. The demand for green hydrogen is expected to grow as countries and companies aim to reduce their carbon footprints, making purification a critical factor in achieving these goals. High-purity green hydrogen will be essential for applications in industries that demand sustainability and quality.

Companies producing or using green hydrogen should prioritize purifiers that are optimized for renewable energy sources. Staying informed about advancements in green hydrogen purification technology will help businesses remain competitive in the evolving clean energy landscape. Marketing green hydrogen as part of a brand’s commitment to sustainability can attract eco-conscious clients and investors who value sustainable practices.

8. Use of Catalytic Purification for Improved Efficiency

Catalytic purification involves using a catalyst to remove specific impurities from hydrogen gas, such as carbon monoxide and methane, through chemical reactions. Catalysts, like platinum or palladium, facilitate reactions that convert contaminants into harmless compounds, which can then be removed from the hydrogen stream. This method is widely used in industries where hydrogen purity is critical, such as ammonia synthesis and petrochemical processing. Companies that utilize catalytic purifiers benefit from an efficient purification process with a higher tolerance for various impurities. For instance, many industrial facilities integrate catalytic purification with other systems to ensure optimal purity levels for their specific requirements.

Catalytic purification is highly effective at removing complex impurities that other methods may not handle as efficiently, making it essential for industries where even minute impurities can affect product quality. For businesses, the use of catalytic purifiers leads to cleaner hydrogen output, which improves product consistency and extends equipment life. Catalytic methods are also highly efficient and can handle large volumes of hydrogen, making them suitable for high-demand industries. By investing in catalytic purification, companies can achieve greater productivity and ensure adherence to stringent industry standards for hydrogen purity.

Businesses requiring ultra-pure hydrogen should consider catalytic purification as part of their purification strategy. Consulting with experts to determine the appropriate catalyst for their specific contaminants can optimize efficiency. Regular catalyst replacement and monitoring will ensure the system operates effectively, supporting high purity standards and reducing long-term operational costs.

9. Growth of Hybrid Purification Systems for Versatile Applications

Hybrid purification systems combine multiple purification methods, such as PSA, catalytic, and membrane technologies, to achieve optimal hydrogen purity. By using a combination of techniques, hybrid systems can tackle a broader range of contaminants and adapt to varying hydrogen purity requirements. For example, a hybrid system might use membrane technology to separate the bulk of impurities, followed by catalytic purification to remove residual contaminants. Companies in sectors like chemical processing and electronics manufacturing benefit from hybrid purifiers, as they provide flexibility and allow for customized purification tailored to specific needs. Hybrid systems are particularly valuable when dealing with hydrogen streams with mixed impurities that are challenging to purify through a single method.

Hybrid systems offer the versatility needed to meet diverse hydrogen purity standards across industries. For businesses, adopting hybrid purification systems means greater adaptability, as these systems can be fine-tuned for different applications and contaminants. This adaptability translates to more efficient operations and reduced downtime, as hybrid systems are capable of managing a variety of impurities with high accuracy. Moreover, hybrid systems can be customized for different production environments, enabling companies to optimize purification processes according to their unique requirements.

Companies should work with purification providers to design hybrid systems that align with their specific operational needs and purity standards. Regularly evaluating the performance of each component within a hybrid system can ensure continued efficiency. Investing in a well-rounded maintenance plan will maximize system lifespan and adaptability, allowing businesses to respond flexibly to changing industry standards and demands.

10. Emphasis on Energy Efficiency and Low-Carbon Purification Processes

With the push for more sustainable practices, the hydrogen purification industry is focusing on energy-efficient and low-carbon purification technologies. Advanced purification methods, like pressure swing adsorption (PSA) and membrane technologies, are being optimized to reduce energy consumption and carbon emissions. Companies like Air Products and Praxair are leading the charge by designing purification systems that integrate renewable energy sources, such as solar or wind, to power the purification process. These energy-efficient systems are not only reducing operational costs but also supporting the global transition to low-carbon energy solutions. For instance, some systems incorporate heat recovery mechanisms to minimize energy use, making hydrogen purification processes more sustainable.

Energy efficiency and low-carbon purification are critical to reducing the overall environmental impact of hydrogen production. For companies, adopting energy-efficient purification systems aligns with sustainability goals and helps lower energy costs, making operations more economically viable. This trend is particularly relevant for businesses aiming to produce green hydrogen, as energy-efficient purifiers help ensure that the entire production process maintains a low-carbon footprint. By adopting these systems, companies contribute to the global effort to combat climate change while enhancing their own environmental reputation, which can be a significant competitive advantage in today’s eco-conscious market.

Businesses should prioritize purification technologies with energy-efficient features, such as heat recovery or renewable energy integration. Conducting an energy audit can help identify areas for improvement and ensure the purification process is as sustainable as possible. Marketing the company’s commitment to energy-efficient and low-carbon purification can also attract eco-conscious customers and investors, further supporting the brand’s reputation for sustainability.

Common Questions About Hydrogen Purifiers

- How do hybrid purification systems work?

Hybrid purification systems combine multiple purification methods, such as catalytic, PSA, and membrane technologies, to address a wide range of contaminants and achieve optimal hydrogen purity. - What are catalytic purifiers, and when are they used?

Catalytic purifiers use catalysts, like platinum or palladium, to remove specific impurities from hydrogen gas. They’re ideal for industries where high purity is essential, as they effectively target complex contaminants. - Why is energy efficiency important in hydrogen purification?

Energy-efficient purification reduces operating costs and minimizes the environmental impact of hydrogen production, aligning with sustainability goals and supporting the transition to low-carbon energy. - Can renewable energy be used in hydrogen purification?

Yes, some purification systems integrate renewable energy sources like solar or wind to power the process, making hydrogen purification more sustainable and lowering carbon emissions. - How does hybrid purification benefit businesses?

Hybrid systems provide flexibility and efficiency by combining different purification methods, making them adaptable to varying purity standards and reducing operational downtime.

The hydrogen purification industry is advancing with technologies and practices that make hydrogen more accessible, sustainable, and reliable. From hybrid purification systems and energy-efficient designs to the integration of AI and IoT, these trends support diverse industries in meeting their hydrogen purity requirements while enhancing operational efficiency. By embracing these advancements, companies can ensure that they’re prepared for the future of clean energy and contribute to the global movement towards a sustainable hydrogen economy. The growing emphasis on hydrogen purification will continue to shape the industry, offering new opportunities for innovation and cleaner energy solutions.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices