-

Email Us

- Top Reports

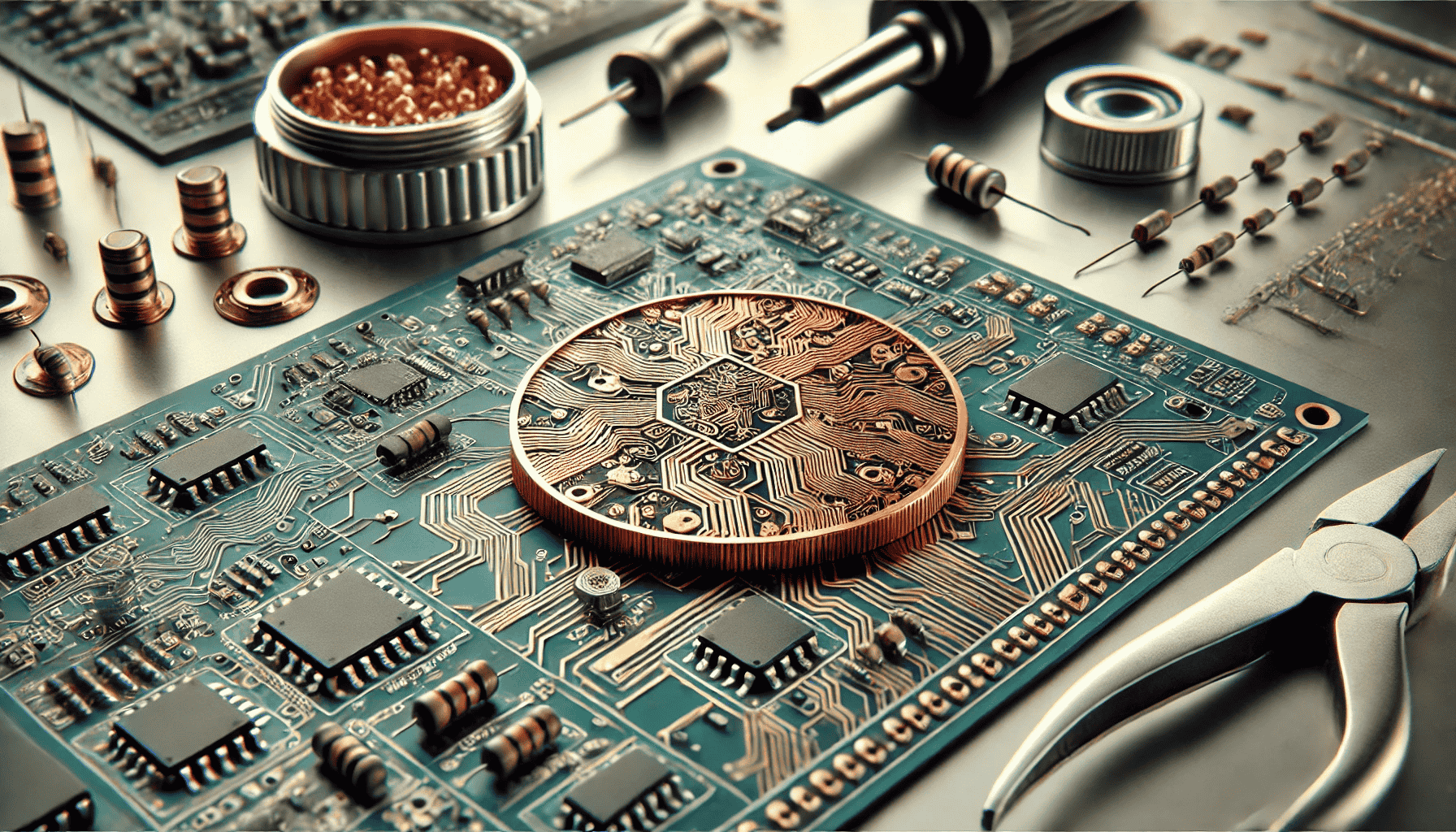

Top 10 Trends in Copper Coin PCBs: Innovations, Applications, and Industry Insights

Posted On 14 November, 2024

Copper Coin PCBs (Printed Circuit Boards) are emerging as essential components in high-performance electronics, especially in applications where heat dissipation is crucial. By incorporating a "copper coin" or an embedded metal core directly within the PCB, these designs enable efficient heat transfer from electronic components, enhancing performance and durability. This comprehensive guide explores the latest trends in Copper Coin PCBs, discussing real-world applications, insights, and practical tips for businesses to leverage this technology effectively.

Now Get Sample PDF Report on : Copper Coin PCB Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=96919

1. Increasing Demand for Efficient Heat Dissipation Solutions

Copper Coin PCBs are becoming increasingly popular in industries where managing heat effectively is critical, such as power electronics, LED lighting, and automotive systems. A copper coin embedded in the PCB allows heat to flow from the component to the board, dissipating heat more efficiently than traditional designs. For instance, high-power LEDs in lighting systems benefit from Copper Coin PCBs, as they prevent overheating and maintain consistent light output. Companies are adopting Copper Coin PCBs in devices where heat dissipation directly impacts performance and reliability, helping to ensure longer product lifespans and greater user satisfaction.

Effective heat dissipation is essential for the longevity and performance of electronic devices, particularly in high-power applications. Poor heat management can lead to device malfunctions, reduced efficiency, and even safety risks. Copper Coin PCBs provide a reliable solution by conducting heat away from sensitive components, ensuring stability and functionality. For businesses, adopting Copper Coin PCBs in heat-sensitive applications can reduce the risk of overheating, improve product reliability, and enhance overall performance, giving them a competitive edge.

Companies in industries with high power requirements should consider integrating Copper Coin PCBs into their products. Working with PCB manufacturers specializing in heat management solutions can provide custom designs that meet specific thermal needs. Testing Copper Coin PCBs in prototype stages can also help fine-tune designs for optimal heat dissipation.

2. Adoption of Copper Coin PCBs in Electric Vehicles (EVs)

The rise of electric vehicles (EVs) has accelerated the demand for durable and high-performance PCBs that can handle the unique requirements of EV systems, particularly in battery management and power distribution. Copper Coin PCBs are increasingly used in EV control units and battery systems, where they help manage the heat generated by high-power components. For example, Copper Coin PCBs in EV battery management systems enhance thermal regulation, improving battery efficiency and longevity. Major EV manufacturers are now collaborating with PCB suppliers to develop custom Copper Coin PCBs that align with their thermal management needs.

As EVs grow in popularity, the need for reliable, heat-resistant electronics becomes more pressing. Copper Coin PCBs provide an effective solution for EV applications, where thermal management is crucial for safety, efficiency, and battery life. For manufacturers, adopting Copper Coin PCBs in EV systems supports longer-lasting battery performance, reduces the likelihood of overheating, and improves overall vehicle safety. This trend positions Copper Coin PCBs as a critical component in the evolution of the EV industry.

EV manufacturers should work closely with PCB suppliers to design Copper Coin PCBs tailored to their battery and power management requirements. Conducting thermal analysis during development can help optimize PCB placement and layout. Highlighting the benefits of Copper Coin PCBs in marketing materials can also appeal to consumers interested in high-performance, durable EV technology.

3. Enhanced Reliability for High-Power LED Lighting

High-power LED lighting systems require robust heat management to prevent performance degradation over time. Copper Coin PCBs have proven effective in LED applications, where they help maintain optimal operating temperatures, preserving light output and color consistency. In street lighting and industrial settings, where LEDs operate continuously, Copper Coin PCBs enable effective thermal control, enhancing energy efficiency and longevity. Companies manufacturing LED systems are increasingly using Copper Coin PCBs to ensure reliable performance in demanding environments.

In LED lighting, thermal management directly affects brightness, color quality, and longevity. Without proper heat dissipation, LEDs can experience early failure and diminished performance. Copper Coin PCBs address these issues by conducting heat away from LEDs, preserving their brightness and color accuracy. This trend allows businesses to offer high-quality, durable lighting solutions that meet the demands of commercial and industrial applications, establishing trust with clients and reducing maintenance costs.

LED manufacturers should prioritize Copper Coin PCBs in high-power lighting systems. Collaborating with PCB suppliers to design optimized thermal pathways will maximize the effectiveness of Copper Coin technology. Marketing Copper Coin-enhanced lighting products as energy-efficient and long-lasting can attract clients in sectors prioritizing performance and durability.

4. Use in High-Frequency Devices and Communication Equipment

Copper Coin PCBs are gaining traction in high-frequency devices and communication equipment, where precision and stability are essential. High-frequency signals generate considerable heat, which can interfere with signal integrity if not properly managed. For example, routers and telecommunications equipment with Copper Coin PCBs maintain more stable temperatures, ensuring reliable signal transmission. Communication companies are integrating Copper Coin PCBs to improve device efficiency and stability in high-frequency environments, where maintaining signal quality is crucial.

High-frequency devices require exceptional thermal management to prevent signal degradation caused by temperature fluctuations. Copper Coin PCBs help stabilize the device temperature, preserving signal quality and enhancing overall system performance. For companies, adopting Copper Coin PCBs in communication devices ensures that high-frequency equipment operates at peak efficiency, meeting customer expectations for performance and reliability. This trend highlights Copper Coin PCBs as a solution for maintaining quality in demanding, high-frequency applications.

Businesses involved in high-frequency applications should explore Copper Coin PCBs as a solution for enhanced signal stability and thermal management. Collaborating with PCB designers specializing in high-frequency layouts can optimize designs for minimal interference. Emphasizing the stability and performance benefits of Copper Coin PCBs in communication equipment can also appeal to clients focused on reliability.

5. Growing Popularity in Consumer Electronics

Consumer electronics, from smartphones to gaming consoles, generate substantial heat, especially as devices become more powerful. Copper Coin PCBs provide a solution for managing heat in compact, high-performance devices. For example, gaming consoles with Copper Coin PCBs can handle prolonged use without overheating, ensuring consistent performance for users. Consumer electronics companies are increasingly incorporating Copper Coin PCBs to enhance durability, prevent overheating, and improve user experience, addressing the demand for reliable and long-lasting products.

As consumer expectations for performance and reliability rise, managing heat in electronic devices is essential to prevent malfunctions and maintain product quality. Copper Coin PCBs allow consumer electronics manufacturers to create devices that perform efficiently even under heavy use. For businesses, using Copper Coin PCBs in product design supports higher customer satisfaction and reduces the risk of returns or repairs due to overheating, positioning the brand as a leader in quality.

Consumer electronics companies should consider using Copper Coin PCBs for heat-sensitive applications, such as gaming devices and mobile phones. Testing Copper Coin designs under different conditions can help ensure optimal performance. Highlighting the enhanced durability of Copper Coin PCBs in marketing can attract consumers looking for high-quality, reliable electronics.

6. Increasing Role in Power Supply Units (PSUs)

Power supply units (PSUs) are critical components in many applications, from industrial machinery to renewable energy systems, where heat management is key to efficiency and safety. Copper Coin PCBs in PSUs facilitate better thermal regulation, preventing overheating in high-power environments. For instance, PSUs in data centers that rely on Copper Coin PCBs experience improved reliability, minimizing the risk of power failures. This trend is leading to broader adoption of Copper Coin PCBs in power-intensive settings, where consistent performance is essential.

Effective heat dissipation in PSUs directly impacts performance, reliability, and operational lifespan. Copper Coin PCBs ensure that PSUs maintain safe operating temperatures, reducing the likelihood of failure and extending the life of power systems. For companies, using Copper Coin PCBs in PSUs means lower maintenance costs, improved energy efficiency, and enhanced customer trust in their products. This trend emphasizes Copper Coin PCBs as a solution for power reliability in demanding environments.

Companies that manufacture power supplies or work in power-intensive sectors should consider Copper Coin PCBs to improve heat regulation. Engaging with PCB suppliers who specialize in high-power applications can help tailor solutions to meet specific requirements. Marketing PSUs with Copper Coin PCBs as reliable and efficient can attract clients looking for high-performance power solutions.

7. Customized Designs for Enhanced Thermal Pathways

Copper Coin PCBs allow for custom designs that optimize thermal pathways for specific applications. Engineers can strategically place copper coins in areas with the highest heat generation, such as under power transistors or processors, to enhance heat transfer. For example, in automotive applications, custom Copper Coin PCB designs help manage the intense heat generated in engine control units (ECUs). Customization enables companies to achieve precise thermal management solutions that align with the unique requirements of each application.

Customization is essential for applications with unique thermal demands, such as automotive and industrial electronics. Tailoring Copper Coin PCBs to specific designs improves overall heat dissipation, enhancing device performance and longevity. For businesses, customized Copper Coin PCBs provide a competitive advantage by ensuring that products operate optimally, even in harsh environments. This trend highlights the versatility of Copper Coin technology, making it adaptable for a wide range of applications.

Companies should work closely with PCB manufacturers to develop customized Copper Coin designs that target high-heat areas. Conducting thermal simulations during the design phase can help identify optimal copper placement. Emphasizing the benefits of custom Copper Coin PCBs in product specifications can appeal to clients looking for performance-focused solutions.

8. Adoption in Renewable Energy Systems

Renewable energy systems, including solar inverters and wind power controllers, often operate in high-temperature environments. Copper Coin PCBs are being adopted in renewable energy components to manage heat and ensure reliable performance. For example, solar inverters with Copper Coin PCBs maintain stable temperatures, improving efficiency and preventing thermal-related failures. Renewable energy companies are turning to Copper Coin PCBs to enhance the resilience and reliability of their systems, supporting sustainable energy goals.

Effective thermal management in renewable energy systems is crucial for efficiency and equipment lifespan. Copper Coin PCBs provide renewable energy companies with a robust solution for managing the heat generated by power conversion processes. By improving thermal regulation, Copper Coin PCBs support stable energy output and reduce maintenance requirements. For the renewable sector, this trend positions Copper Coin PCBs as a valuable component for meeting sustainability goals.

Renewable energy companies should evaluate Copper Coin PCBs for high-temperature applications, such as solar or wind power systems. Working with PCB suppliers who understand renewable energy requirements can ensure designs that maximize energy efficiency. Highlighting the durability and reliability of Copper Coin-enhanced systems can attract customers focused on sustainable energy.

9. Integration with Advanced Thermal Simulation Tools

To optimize Copper Coin PCB designs, companies are increasingly using advanced thermal simulation tools that predict heat flow and temperature distribution within the PCB. By simulating different thermal scenarios, engineers can strategically place copper coins to maximize heat dissipation and prevent hot spots. For instance, in high-performance computing (HPC) systems, where components operate at peak loads, thermal simulation helps ensure even heat distribution, preventing localized overheating. Companies like Altium and Ansys provide software solutions that enable PCB designers to create accurate thermal models, helping them design Copper Coin PCBs that are more efficient and reliable.

Using thermal simulation in Copper Coin PCB design enhances precision and efficiency, leading to improved performance and durability. Simulation tools allow engineers to optimize PCB layouts, ensuring that copper coins are placed in the most effective locations. For companies, adopting simulation tools means fewer design iterations, reduced production costs, and improved quality assurance. This trend emphasizes the role of thermal simulation in modern PCB design, where accuracy and efficiency are paramount for achieving high-performance outcomes.

PCB manufacturers and designers should invest in thermal simulation software to optimize Copper Coin PCB layouts. Collaborating with simulation experts can also help companies get the most out of their design processes. Marketing the benefits of simulation-driven designs, such as enhanced performance and reliability, can appeal to clients in need of high-quality, efficient PCBs.

10. Use of Copper Coin PCBs in High-Precision Medical Equipment

In the medical field, electronic devices such as imaging equipment and diagnostic machines often require precise thermal management to function accurately and safely. Copper Coin PCBs are increasingly being used in medical devices that generate significant heat, such as CT scanners and MRI machines. These systems rely on stable temperature control to deliver reliable results and protect sensitive components. For example, an MRI machine with Copper Coin PCBs benefits from steady temperature regulation, ensuring that high-powered components can operate continuously without compromising the quality of imaging.

Precision is critical in medical equipment, as any thermal fluctuations can affect performance, potentially impacting patient care. Copper Coin PCBs provide medical device manufacturers with a reliable solution for maintaining optimal operating temperatures, which is essential for both device accuracy and longevity. For companies, using Copper Coin PCBs in medical devices supports compliance with stringent industry standards and enhances trust among healthcare providers. This trend highlights Copper Coin PCBs as a valuable asset in high-precision fields, where thermal stability is directly tied to performance and safety.

Medical device manufacturers should consider Copper Coin PCBs for high-heat applications, collaborating with PCB suppliers experienced in healthcare standards. Conducting rigorous thermal testing will help ensure compliance with medical regulations. Marketing Copper Coin-enhanced devices as reliable and precise can help attract healthcare providers looking for top-tier medical technology.

Common Questions About Copper Coin PCBs

- What are Copper Coin PCBs, and why are they used?

Copper Coin PCBs feature embedded copper sections that dissipate heat from high-power components, improving thermal management and device reliability. They are used in applications where heat dissipation is crucial for performance and safety. - How do Copper Coin PCBs benefit electric vehicles?

Copper Coin PCBs enhance heat management in EV components, such as battery management systems, allowing for safer, more efficient operation. They help maintain optimal temperatures, improving battery life and overall vehicle performance. - Are Copper Coin PCBs suitable for high-frequency devices?

Yes, Copper Coin PCBs are well-suited for high-frequency devices, as they stabilize temperatures, preventing heat-related signal degradation. This makes them ideal for communication equipment where consistent performance is essential. - What industries benefit most from Copper Coin PCBs?

Industries including automotive, consumer electronics, renewable energy, medical devices, and high-power LED lighting benefit significantly from Copper Coin PCBs due to their thermal management capabilities. - How are Copper Coin PCBs customized for specific applications?

PCB designers use thermal simulation and custom layouts to place copper coins in high-heat areas, optimizing heat dissipation based on the specific needs of each application.

The Copper Coin PCB industry is evolving rapidly, with innovations focused on enhancing thermal management, reliability, and versatility across various sectors. Trends such as advanced thermal simulation, modular designs, and applications in EVs, renewable energy, and medical equipment showcase the adaptability and value of Copper Coin PCBs. By adopting these technologies, companies can achieve higher performance, improved safety, and longer-lasting devices, positioning themselves as leaders in quality and innovation. As demand for efficient heat dissipation continues to rise, Copper Coin PCBs will play an increasingly important role in advancing technology across multiple industries.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices