-

Email Us

- Top Reports

Top 10 Trends in Compact Gas-Liquid Separators: Efficiency, Innovation, and Industry Insights

Posted On 14 November, 2024

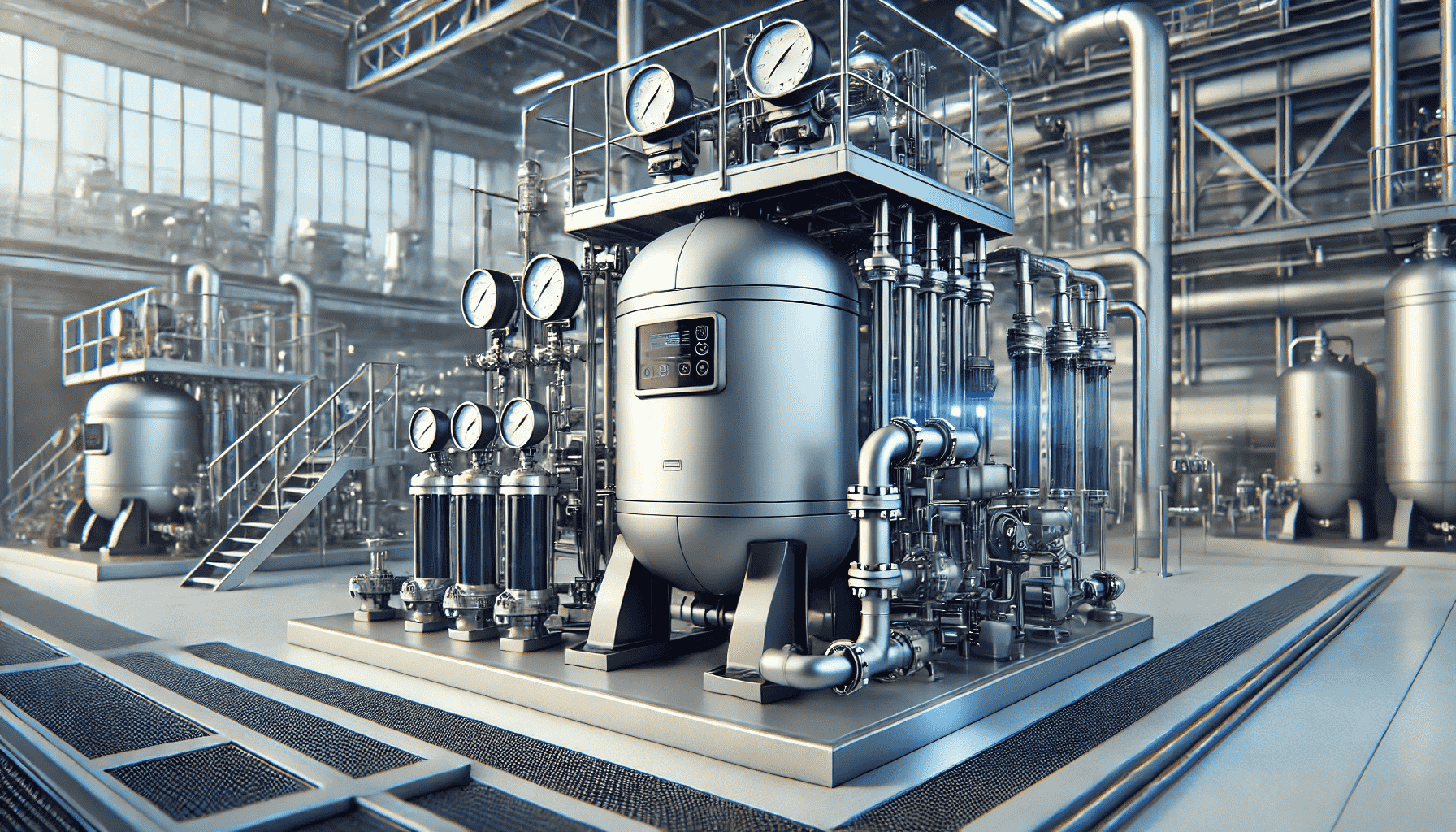

Compact gas-liquid separators play a crucial role in industries where the separation of gas and liquid phases is essential for safe and efficient operations. These devices are widely used in sectors like oil and gas, chemical processing, and water treatment to separate gas from liquids in various industrial processes. As industries demand more efficient and space-saving solutions, compact gas-liquid separators have evolved to meet these needs. This guide explores the top 10 trends in compact gas-liquid separators, offering insights into the latest advancements, practical applications, and actionable tips for businesses looking to leverage these innovative technologies.

Now Get Sample PDF Report on : Compact Gas-Liquid Separator Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=24145

1. Emphasis on High-Efficiency Separation Technologies

Detailed Example: Recent advancements in high-efficiency separation technologies have improved the performance of compact gas-liquid separators. Manufacturers are now designing separators with enhanced internal components, such as cyclone-based or centrifugal separators, which increase the separation efficiency by rapidly spinning the gas-liquid mixture. This design allows heavier liquid particles to settle quickly while gas is drawn out efficiently. An example of this technology is the centrifugal separator, which has become popular in the oil and gas industry for its ability to handle high-pressure conditions and maintain efficiency.

Why It Matters: High-efficiency separation is critical for industries that rely on quick and accurate separation of gases and liquids, reducing downtime and minimizing operational costs. For businesses, improved efficiency means reduced maintenance, lower energy costs, and less wear on equipment. Efficient separators also contribute to a safer work environment by preventing unwanted gas leaks and liquid carryover.

Actionable Tip: Companies should assess their current separation processes to identify areas where high-efficiency separators can improve performance. Collaborating with separation technology providers can help identify the best solutions for specific operational needs. Highlighting the efficiency improvements from these separators in reports can help justify the investment in advanced separation technology to stakeholders.

2. Integration of Compact Designs for Space-Constrained Operations

Detailed Example: With industries increasingly seeking to optimize limited space, compact gas-liquid separators have been designed to fit within smaller footprints. Compact designs are especially valuable in offshore drilling rigs, refineries, and industrial plants where space is at a premium. Horizontal and vertical configurations allow for flexible installation, adapting to varying layouts. The compact size doesn’t compromise efficiency, as these separators are engineered to maintain effective separation despite the smaller form factor. For instance, some oil rigs use compact inline separators that integrate directly into the piping system, saving space and simplifying maintenance.

Why It Matters: Compact designs reduce installation and operational costs by fitting into tighter spaces without requiring significant infrastructure modifications. For businesses, this trend is advantageous because it enables more efficient use of space, minimizes footprint requirements, and allows separators to be installed in locations where traditional separators may not fit. Compact separators are also ideal for mobile and remote applications, such as on offshore rigs or in temporary processing facilities.

Actionable Tip: Industries facing space limitations should prioritize compact gas-liquid separators and explore models specifically designed for small-scale installations. Engaging with suppliers to find separators tailored to specific spatial constraints can enhance overall facility layout and workflow. Highlighting the space-saving benefits of these designs can also appeal to decision-makers focused on optimizing plant layouts.

3. Advancements in Automated and Smart Separation Systems

Detailed Example: Automation and smart technology integration are transforming the functionality of compact gas-liquid separators. Modern separators are equipped with sensors, flow meters, and digital controllers that allow for real-time monitoring and adjustment of separation parameters. Automation features enable separators to adjust for changes in flow rate, pressure, or composition of the gas-liquid mixture, enhancing precision and reducing the need for manual oversight. For instance, some separators use IoT-enabled sensors to monitor gas and liquid levels, alerting operators of any discrepancies or maintenance needs.

Why It Matters: Automated systems reduce human error and improve operational safety by enabling precise control over separation processes. For businesses, smart separators streamline workflows, reduce labor costs, and ensure continuous monitoring, leading to more reliable and efficient operations. Automation also allows for predictive maintenance, as sensors can detect early signs of wear or potential failures, minimizing downtime and costly repairs.

Actionable Tip: Industries looking to modernize their processes should consider investing in automated separators with IoT capabilities. Training staff on the use of digital interfaces and data analysis can maximize the benefits of automation. Demonstrating the cost savings and efficiency improvements from automation can help justify the investment in smart separation technology.

4. Focus on Energy-Efficient Separation Techniques

Detailed Example: Energy efficiency is a priority across all industries, and compact gas-liquid separators are no exception. Manufacturers are developing separators that require less energy by optimizing airflow dynamics and reducing pressure drops. For example, some separators now incorporate vortex flow control to minimize resistance, which reduces the energy needed for gas and liquid separation. Energy-efficient separators are particularly beneficial in applications with high throughput, such as in natural gas processing, where reducing energy consumption can lead to substantial cost savings.

Why It Matters: Energy-efficient separators lower operational costs and reduce carbon emissions, aligning with sustainability goals. For businesses, the use of energy-efficient equipment helps lower utility bills, reduces reliance on non-renewable energy sources, and contributes to corporate sustainability initiatives. Enhanced energy efficiency also strengthens a company’s position in the market by showcasing its commitment to eco-friendly operations.

Actionable Tip: Companies can evaluate the energy consumption of their existing separators and explore options for upgrading to energy-efficient models. Partnering with manufacturers that specialize in energy-saving technologies can offer valuable insights into suitable upgrades. Incorporating energy-efficient equipment into sustainability reports and marketing materials can boost the company’s image as an environmentally responsible operator.

5. Adoption of Multi-Phase Separation for Complex Mixtures

Detailed Example: Multi-phase separation systems are gaining traction, particularly in industries where gas-liquid mixtures contain additional phases, such as solids or different types of liquids. Compact gas-liquid separators with multi-phase capabilities can separate gas, oil, water, and solids simultaneously, reducing the need for multiple units. For example, in the oil extraction industry, separators that can handle water, oil, gas, and sediment help streamline operations and reduce equipment costs. These systems are particularly valuable in offshore drilling where space and resources are limited.

Why It Matters: Multi-phase separation reduces the complexity of industrial setups and enhances efficiency by combining multiple separation processes into a single unit. For businesses, multi-phase separators reduce capital expenditure and maintenance costs, as fewer devices are needed to handle complex mixtures. By simplifying the separation process, companies can optimize workflows and enhance overall productivity.

Actionable Tip: Industries dealing with complex mixtures should consider multi-phase separation systems to streamline processes and reduce equipment costs. Collaborating with manufacturers to find multi-phase solutions tailored to specific applications can enhance operational efficiency. Demonstrating the cost savings and operational benefits from multi-phase systems can strengthen the business case for these investments.

6. Use of Corrosion-Resistant Materials for Durability

Detailed Example: Corrosion resistance is a key consideration for gas-liquid separators, especially in industries handling corrosive gases or liquids. Manufacturers are now using corrosion-resistant materials, such as stainless steel, titanium, and specialized coatings, to increase the lifespan of separators. Offshore platforms, for example, require separators that can withstand exposure to saltwater, harsh chemicals, and fluctuating temperatures. By incorporating durable materials, separators can resist corrosion, reducing the frequency of repairs or replacements.

Why It Matters: Corrosion-resistant separators lower maintenance costs and improve safety by reducing the risk of equipment failure. For businesses, investing in durable separators means fewer interruptions to operations, lower maintenance expenses, and enhanced safety. The use of corrosion-resistant materials also demonstrates a commitment to quality, which can improve stakeholder confidence and reduce overall lifecycle costs.

Actionable Tip: Companies in harsh environments should prioritize separators made from corrosion-resistant materials to ensure longevity and reliability. Regular maintenance checks can further enhance durability and ensure optimal performance. Promoting the durability and reliability of corrosion-resistant separators in marketing materials can reassure customers of their quality and long-term value.

7. Increased Focus on Modular Separator Systems for Scalability

Detailed Example: Modular separator systems allow businesses to scale their separation capacity by adding or removing units as needed. This flexibility is particularly beneficial in industries where demand fluctuates or where facilities are expanding. Modular separators are designed to be interconnected, allowing companies to quickly increase capacity without replacing entire systems. For example, in chemical processing plants, modular separators enable companies to adjust their operations according to production requirements, offering a flexible and scalable solution.

Why It Matters: Modular systems provide flexibility and scalability, allowing businesses to adapt to changing demands without significant capital expenditure. For companies, modular separators reduce the risk of over- or under-sizing equipment, which can lead to inefficiencies. Scalability is especially valuable in industries that face seasonal demand variations or are undergoing rapid expansion, as it allows companies to grow in a cost-effective manner.

Actionable Tip: Industries experiencing growth or fluctuating demand should consider modular separator systems to maintain flexibility. Collaborating with manufacturers on scalable solutions can ensure that separators align with current and future production needs. Emphasizing the cost savings and flexibility of modular systems in business proposals can support long-term planning and resource management.

8. Enhanced Safety Features and Compliance with Industry Standards

Detailed Example: Safety is paramount in industries using gas-liquid separators, and manufacturers are focusing on integrating enhanced safety features. Modern separators now include pressure relief valves, emergency shut-off systems, and automated safety monitoring to prevent accidents. Compliance with industry standards, such as the American Petroleum Institute (API) standards for oil and gas, ensures that separators meet stringent safety and quality requirements. These features are crucial in high-risk environments, such as chemical processing plants and oil refineries, where gas leaks or equipment malfunctions can have serious consequences.

Why It Matters: Enhanced safety features reduce the risk of accidents and ensure compliance with industry regulations, protecting employees and the environment. For businesses, prioritizing safety reduces liability, enhances workplace morale, and demonstrates a commitment to responsible operations. Compliance with industry standards is also essential for obtaining certifications and approvals, which can expand business opportunities.

Actionable Tip: Industries with high safety requirements should invest in separators with advanced safety features and ensure regular inspections and maintenance. Training employees on safety protocols and compliance standards can further improve safety outcomes. Highlighting safety features and compliance in marketing materials can appeal to clients seeking reliable and responsible equipment.

9. Adoption of Low-Pressure Drop Designs for Enhanced Efficiency

Detailed Example: Compact gas-liquid separators with low-pressure drop designs are gaining popularity, especially in applications where pressure management is critical. Low-pressure drop separators are engineered to minimize resistance, allowing fluids and gases to pass through with minimal energy loss. This design is beneficial in natural gas processing, where pressure conservation is crucial for efficiency and cost-effectiveness. By optimizing the internal structure of separators, manufacturers can reduce the energy required to maintain separation without compromising performance.

Why It Matters: Reducing pressure drop improves operational efficiency, leading to lower energy consumption and reduced operating costs. For businesses, adopting low-pressure drop separators can result in significant savings, especially in facilities with high fluid and gas throughput. Low-pressure designs also extend equipment life by reducing the strain on pumps and compressors, making them ideal for long-term industrial applications.

Actionable Tip: Companies looking to optimize their energy usage should consider low-pressure drop separators and collaborate with manufacturers to select models that fit their operational requirements. Monitoring pressure levels regularly can also help in maintaining efficiency and identifying potential issues early. Highlighting energy savings from these designs can be a strong selling point when presenting to stakeholders focused on reducing operational costs.

10. Increasing Demand for Mobile and Portable Separator Units

Detailed Example: Mobile and portable gas-liquid separator units are becoming essential in industries that require flexibility and on-site separation. These portable units are particularly valuable in field operations, such as oil and gas exploration, where temporary setups are common. For instance, mobile separators are used in remote drilling sites to process fluids and gases on-site, reducing the need to transport mixtures to a separate facility. These units are designed to be easily transportable and can operate efficiently under varying environmental conditions.

Why It Matters: Mobile separators offer flexibility, allowing companies to conduct separation processes on-site, reducing transportation costs and enhancing efficiency. For businesses, portable units support faster response times in temporary or remote projects, enabling immediate processing and reducing logistical complexities. Mobile separators also provide a cost-effective solution for industries that require flexibility, such as seasonal operations or short-term projects.

Actionable Tip: Companies involved in fieldwork or remote operations should consider mobile separator units to improve efficiency and reduce transport costs. Partnering with suppliers that offer rental or lease options for mobile units can help manage costs. Showcasing the advantages of portable separators in project proposals can emphasize the value of on-site processing, attracting clients seeking flexible and efficient solutions.

Common Questions About Compact Gas-Liquid Separators

- Can compact gas-liquid separators handle varying pressures efficiently?

Yes, many compact separators are designed to manage pressure variations effectively, especially those with low-pressure drop designs that minimize energy loss. - Are portable gas-liquid separators suitable for long-term projects?

While portable units are ideal for temporary and remote projects, some models are robust enough for long-term use, especially in operations that require flexibility. - What maintenance is required for compact separators in harsh environments?

Regular inspection and cleaning, along with corrosion-resistant materials, are essential to maintain performance in harsh conditions. - How do multi-phase separators work with complex mixtures?

Multi-phase separators are designed to separate gas, liquid, and solid phases, making them suitable for industries like oil extraction, where complex mixtures are common. - Is automation necessary for small-scale gas-liquid separators?

Automation enhances precision and reduces manual monitoring, making it beneficial for both small and large-scale operations by improving efficiency and safety.

Compact gas-liquid separators are evolving to meet the diverse needs of modern industries, with advancements in efficiency, portability, and automation. From low-pressure designs and multi-phase capabilities to mobile solutions and corrosion-resistant materials, these trends are shaping the future of phase separation technology. By embracing these innovations, businesses can enhance operational efficiency, reduce costs, and ensure safer, more sustainable processes. Compact separators are becoming indispensable tools in various industries, providing flexibility, scalability, and high performance in compact, efficient forms. As industries continue to seek efficient and adaptable solutions, compact gas-liquid separators will play a key role in meeting the demands of an ever-evolving industrial landscape.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices