-

Email Us

- Top Reports

A Comprehensive Guide to Pipe Coating Companies: Trends, Industry Insights, and Best Practices

Posted On 09 October, 2024

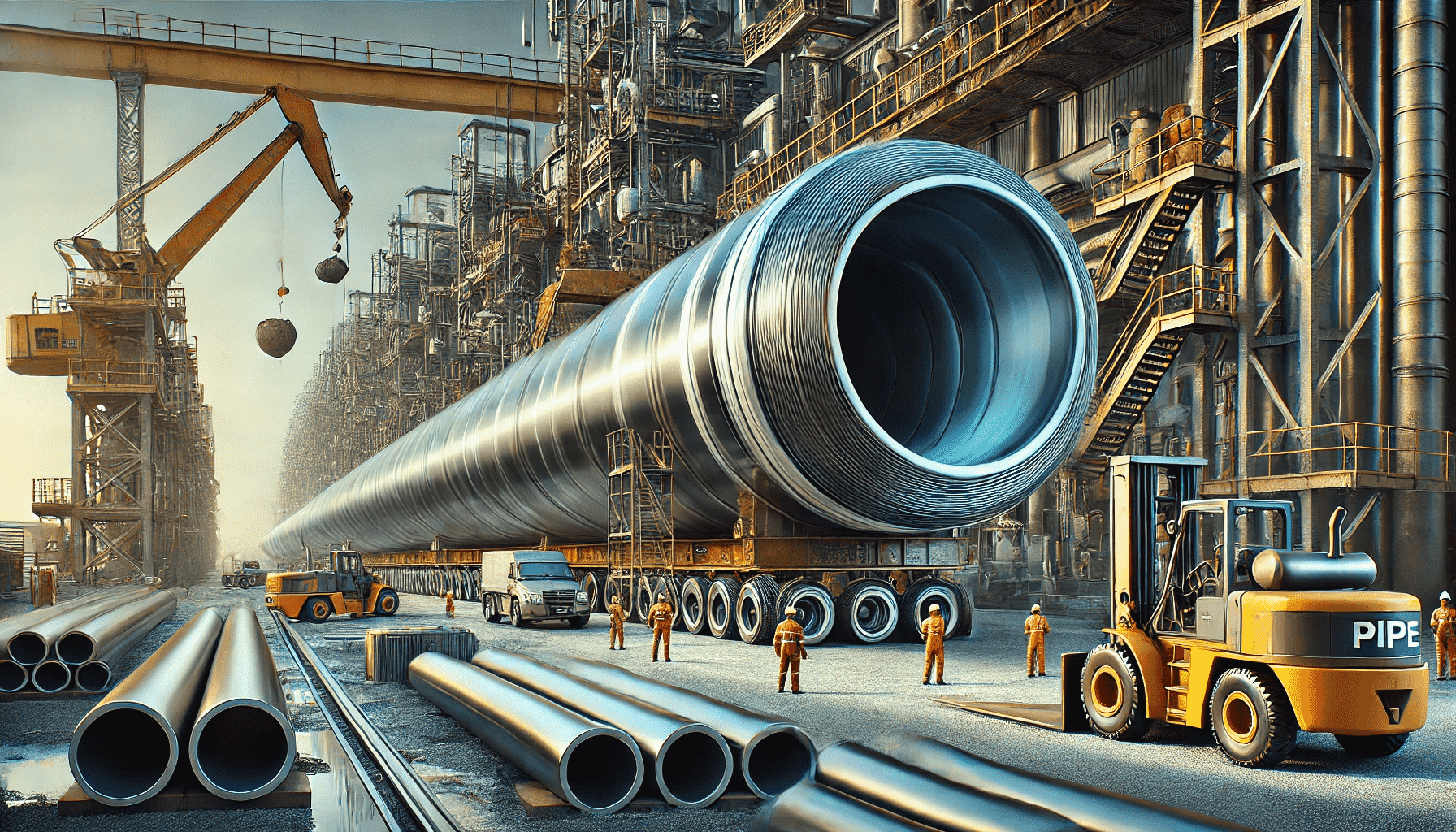

Pipe coating companies play an essential role in multiple industries by providing protective and functional coatings that enhance the durability, performance, and longevity of pipelines. From oil and gas to water supply and chemical transport, coated pipes are vital for preventing corrosion, ensuring efficient flow, and safeguarding against environmental damage. In this guide, we will explore the importance of pipe coating companies, dive into current industry trends, and provide insights into how businesses can leverage these services effectively. This analysis will also include expert opinions, data, and case studies to provide a well-rounded view of the pipe coating industry.

Pipelines are the veins of various industries, transporting critical resources across vast distances. However, these pipelines face harsh environmental conditions, chemical exposure, and wear over time. This is where pipe coating companies step in, offering specialized solutions to protect pipelines from corrosion, abrasion, and other forms of damage. Coatings not only extend the lifespan of pipes but also help companies reduce maintenance costs and ensure regulatory compliance.

Now Get Sample PDF Report on : Pipe Coatings Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=55513

Top 10 Trends in Pipe Coating Companies

The pipe coating industry is continuously evolving, driven by technological advancements, regulatory changes, and the growing need for sustainable solutions. Several key trends are shaping this industry, each influencing the way pipe coating companies operate and deliver their services.

The first trend to note is the increasing demand for environmentally friendly coatings. With rising environmental concerns, industries are seeking coatings that are not only effective but also eco-friendly. Companies are developing coatings with low volatile organic compounds (VOCs) and using water-based formulas that have a reduced impact on the environment.

A second trend is the growing use of advanced materials in coatings. Pipe coating companies are experimenting with materials such as epoxy, polyethylene, and polyurethane to provide enhanced protection. These advanced materials offer better resistance to corrosion, heat, and chemicals, making them ideal for use in industries like oil and gas, where pipelines are exposed to harsh conditions.

Another significant trend is the adoption of fusion-bonded epoxy (FBE) coatings. FBE coatings are popular due to their strong adhesion properties and resistance to various forms of corrosion. These coatings are often used in pipelines for water, gas, and oil, as they provide excellent protection against environmental factors and require less maintenance over time.

The fourth trend is the integration of automation in the coating process. Pipe coating companies are increasingly turning to automated systems to apply coatings with greater precision and consistency. Automation not only improves the quality of the coatings but also reduces labor costs and increases efficiency, making it a valuable investment for companies looking to enhance their operations.

In addition to automation, the use of robotics in pipe coating applications is growing. Robots are used to coat hard-to-reach areas, particularly in underground or subsea pipelines, where manual application can be difficult or dangerous. Robotics allows for more accurate and uniform coatings, reducing the likelihood of defects and extending the life of the pipe.

The fifth trend involves the development of high-temperature coatings. As industries like oil and gas operate in extreme temperature conditions, the need for coatings that can withstand high heat has become a priority. Pipe coating companies are developing solutions that maintain their protective properties even under intense heat, ensuring that pipelines remain functional and safe in demanding environments.

The sixth trend shaping the pipe coating industry is the focus on sustainability. Companies are increasingly adopting coatings made from renewable materials or using energy-efficient manufacturing processes. This trend aligns with global efforts to reduce carbon emissions and minimize the environmental impact of industrial activities. Pipe coating companies that embrace sustainability practices are likely to gain a competitive edge in today’s market.

Another important trend is the growth of pipeline rehabilitation services. Rather than replacing old pipelines, many companies are opting to rehabilitate them using specialized coatings that restore the integrity of the pipe. This cost-effective approach reduces the need for new infrastructure while still ensuring that pipelines are protected and capable of carrying out their intended functions.

The eighth trend involves the development of multi-functional coatings. These coatings offer more than just corrosion protection. Some are designed to enhance the flow efficiency of pipelines by reducing friction, while others provide thermal insulation. Multi-functional coatings are particularly useful in industries where pipelines need to perform efficiently while being protected from various external factors.

The ninth trend is the growing demand for localized solutions. Industries operating in different regions may face unique environmental challenges, such as varying humidity levels, soil composition, or exposure to chemicals. Pipe coating companies are developing customized solutions tailored to specific geographic locations to ensure that pipelines are protected in the most effective way possible.

Finally, the adoption of smart coatings is an emerging trend. Smart coatings can detect changes in the pipeline’s condition, such as temperature fluctuations or corrosion levels, and alert operators before significant damage occurs. These coatings are integrated with sensors that monitor the pipeline in real-time, allowing for proactive maintenance and reducing the risk of pipeline failure.

How Pipe Coating Companies Are Changing the Industry

Pipe coating companies are not only keeping up with these trends but also driving innovation in the industry. Through the use of advanced technologies, materials, and application techniques, they are transforming how pipelines are built, maintained, and protected.

One of the most significant ways in which pipe coating companies are changing the industry is through the introduction of sustainable practices. By developing eco-friendly coatings and using energy-efficient processes, these companies are helping industries reduce their environmental footprint. This shift toward sustainability is not only benefiting the environment but also providing companies with a competitive advantage as more clients prioritize eco-conscious solutions.

Additionally, the development of advanced coatings, such as those with high-temperature resistance and multi-functional properties, is allowing industries to operate more efficiently and safely. For example, in the oil and gas sector, pipelines that transport heated fluids or gases require coatings that can withstand extreme temperatures. The introduction of these advanced coatings has enabled companies to maintain pipeline integrity, even under the most challenging conditions.

The rise of automation and robotics is also revolutionizing the pipe coating process. Automated systems ensure that coatings are applied uniformly and consistently, reducing the likelihood of errors and defects. This not only improves the quality of the final product but also increases efficiency by reducing the time and labor required for manual application.

Why Pipe Coating Companies Matter in Today’s Market

The importance of pipe coating companies cannot be overstated, particularly in industries where pipelines are a critical component of infrastructure. From oil and gas to water distribution and chemical processing, pipelines are essential for transporting resources safely and efficiently. Pipe coatings play a vital role in ensuring the longevity, reliability, and safety of these pipelines.

One of the main reasons pipe coating companies matter in today’s market is the growing need for corrosion protection. Pipelines are exposed to various environmental factors that can cause corrosion over time, leading to leaks, contamination, or even catastrophic failures. By providing high-quality coatings, pipe coating companies help prevent these issues, reducing maintenance costs and minimizing downtime.

Moreover, the increasing demand for energy and resources has led to the expansion of pipeline networks across the globe. As new pipelines are constructed and existing ones are rehabilitated, the need for reliable coating solutions is greater than ever. Pipe coating companies are stepping up to meet this demand by offering innovative products and services that ensure pipelines remain operational for decades.

The emphasis on sustainability and environmental responsibility is another reason why pipe coating companies are important. As industries strive to reduce their carbon footprint and adopt greener practices, pipe coating companies that provide eco-friendly solutions are helping businesses achieve these goals. By offering coatings that are free from harmful chemicals and using sustainable production methods, these companies are contributing to a more environmentally conscious future.

Additionally, pipe coating companies play a crucial role in maintaining safety standards in industries where pipeline failure can have severe consequences. In sectors like oil and gas, chemical processing, and water distribution, the failure of a pipeline can lead to environmental damage, safety hazards, and significant financial losses. By providing durable, high-performance coatings, pipe coating companies help ensure that pipelines operate safely and efficiently.

Best Practices for Leveraging Pipe Coating Companies in Business

For businesses that rely on pipelines for their operations, working with pipe coating companies can provide numerous benefits. However, it is essential to follow best practices to ensure that you are getting the most out of these services.

First and foremost, it is important to choose a pipe coating company with experience and expertise in your specific industry. Different industries have different requirements when it comes to pipeline coatings, and working with a company that understands your needs can make all the difference. Whether you need coatings for oil pipelines, water supply lines, or chemical transport, a specialized company will be better equipped to provide the right solutions.

Additionally, businesses should prioritize companies that invest in research and development. The pipe coating industry is continually evolving, and companies that stay at the forefront of technological advancements are more likely to offer innovative products and services. Working with a company that invests in new materials, application techniques, and sustainability practices ensures that your pipeline coatings are up to date with the latest industry standards.

Another best practice is to consider the environmental impact of the coatings used. With sustainability becoming a key consideration for many industries, opting for eco-friendly coatings can help your business meet environmental regulations and reduce its carbon footprint. Ask your pipe coating provider about the environmental credentials of their products and choose coatings that align with your sustainability goals.

It is also crucial to ensure that the coating application process is done correctly. Even the best coatings can fail if they are not applied properly. Working with a pipe coating company that uses automated systems or robotics can help ensure that the coatings are applied uniformly and consistently, reducing the likelihood of defects or premature failure.

Finally, businesses should consider the long-term maintenance needs of their pipelines. Coatings that offer extended durability and require less maintenance can save your company time and money in the long run. Be sure to discuss the expected lifespan and maintenance requirements of different coatings with your provider to make an informed decision.

Pipe coating companies are an essential part of the infrastructure that supports various industries, from energy to water distribution. With technological advancements, growing sustainability concerns, and an increasing need for durable and reliable pipelines, the role of pipe coating companies is more important than ever. By staying at the forefront of industry trends, adopting best practices, and offering innovative solutions, these companies are helping to ensure the safe, efficient, and sustainable operation of pipelines around the world.

For businesses looking to leverage the expertise of pipe coating companies, choosing the right partner is critical. By considering factors such as industry experience, technological advancements, sustainability practices, and long-term maintenance needs, businesses can make informed decisions that protect their pipelines and enhance their overall operations. Whether you are building new pipelines or rehabilitating existing ones, pipe coating companies are an invaluable resource for ensuring the longevity and performance of your infrastructure.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices