-

Email Us

- Top Reports

The Ultimate Guide to Dump Truck Manufacturers: Trends, Innovations, and Best Practices

Posted On 05 November, 2024

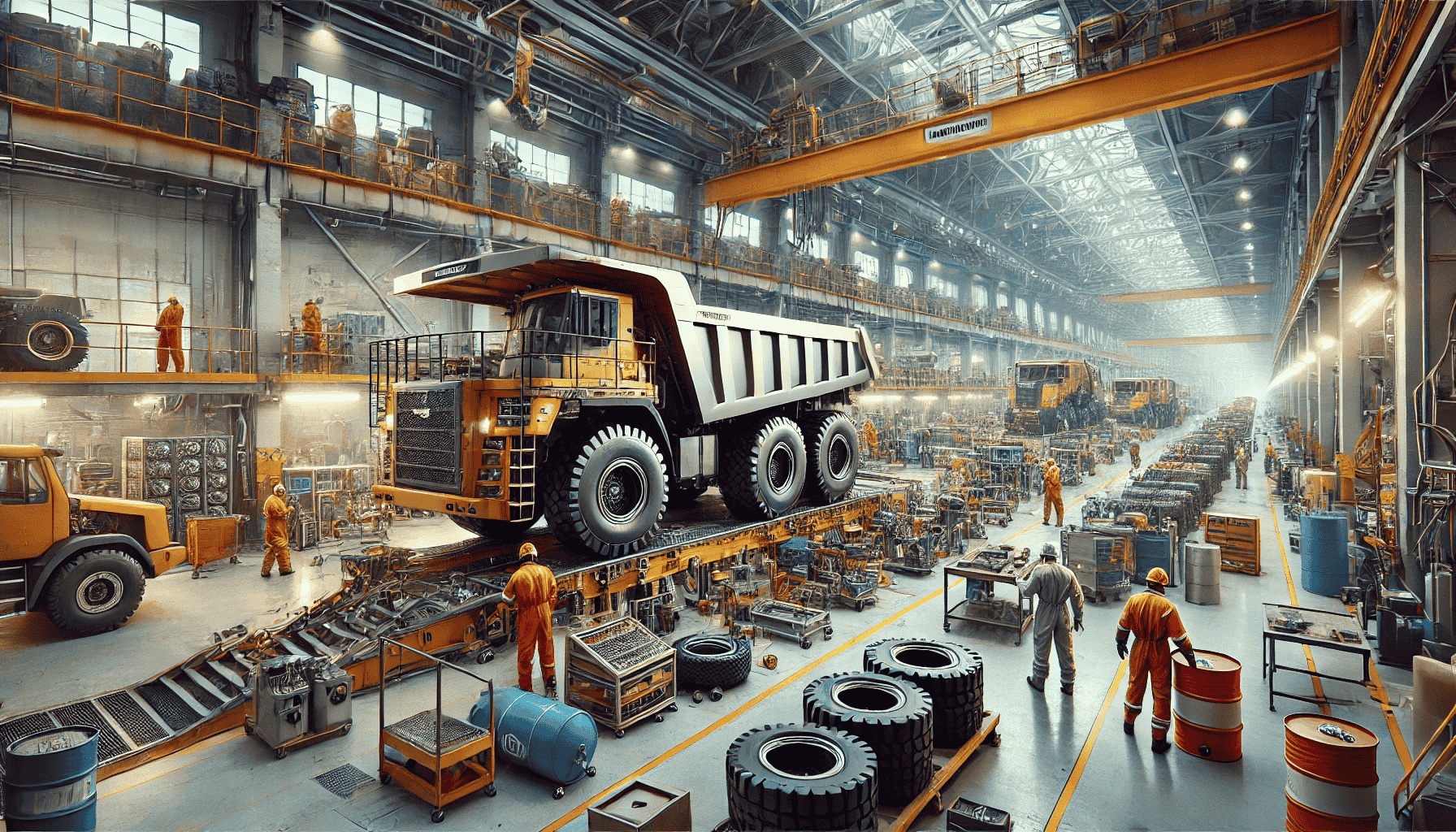

Introduction: Exploring the World of Dump Truck Manufacturing

Dump trucks are essential vehicles in the construction, mining, and logistics industries. These powerful machines handle massive loads and work in challenging conditions, making their quality and reliability crucial to various industries worldwide. As technology advances, dump truck manufacturers are continuously innovating to improve efficiency, safety, and sustainability. This guide provides an in-depth look at the top trends in the dump truck manufacturing industry, examines the technology driving change, and offers actionable tips for leveraging these advancements. By exploring how these trucks are evolving, we gain insight into the future of construction and logistics equipment.

Now Get Sample PDF Report on : Dump Truck Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=347098

Top 10 Trends in Dump Truck Manufacturing

1. Focus on Fuel Efficiency and Reduced Emissions

One of the primary concerns for dump truck manufacturers today is reducing fuel consumption and emissions. The heavy-duty nature of dump trucks means they often consume large amounts of fuel, contributing to environmental pollution. To address this, manufacturers are investing in fuel-efficient engines and eco-friendly technologies.

Advanced fuel management systems help reduce fuel usage by optimizing engine performance and monitoring fuel levels. Some companies are incorporating hybrid technology, combining electric motors with traditional fuel engines to cut emissions and reduce operational costs. With stricter environmental regulations worldwide, dump truck manufacturers who prioritize fuel efficiency gain a competitive advantage and attract clients focused on sustainability.

2. Adoption of Electric and Hybrid Dump Trucks

The shift towards electric and hybrid vehicles is reshaping the dump truck industry. Electric dump trucks are an eco-friendly alternative that reduces carbon emissions and lowers fuel dependency. While fully electric trucks are still in their early stages due to high battery costs and limited range, many manufacturers are working to overcome these challenges.

Hybrid dump trucks, which combine electric power with diesel engines, provide a balance between fuel savings and extended operating times. This hybrid approach allows trucks to operate in electric mode during low-load tasks and switch to diesel for heavy-duty operations. As battery technology improves, we can expect to see more fully electric dump trucks on the market, reducing the industry’s carbon footprint and offering a cleaner alternative.

3. Advanced Telematics and Data Analytics Integration

Telematics systems and data analytics are becoming essential in modern dump trucks. These systems allow fleet managers to monitor vehicle performance, track fuel consumption, and predict maintenance needs. Telematics also enables real-time tracking, allowing companies to optimize routes, reduce idle time, and increase productivity.

Data analytics provides valuable insights into vehicle performance, helping manufacturers design more efficient and durable trucks. By analyzing usage patterns, manufacturers can predict component wear and design better maintenance schedules. This data-driven approach increases uptime and helps fleet operators avoid costly breakdowns. Telematics systems are also beneficial for safety, as they monitor driver behavior and ensure compliance with speed limits and other regulations.

4. Enhanced Safety Features

Safety is a top priority in the dump truck manufacturing industry. With the demanding environments in which these trucks operate, manufacturers are incorporating advanced safety features to protect operators and prevent accidents. Some common safety enhancements include collision avoidance systems, backup cameras, blind-spot monitoring, and automated braking systems.

Modern dump trucks also feature stability control systems to prevent rollovers on uneven terrain. These features not only improve operator safety but also reduce the risk of damage to the vehicle and the surrounding environment. Enhanced safety features make dump trucks a more attractive option for construction and mining companies concerned about worker safety and equipment longevity.

5. Autonomous and Remote-Controlled Dump Trucks

Autonomous dump trucks are a revolutionary trend in the industry. While fully autonomous trucks are still rare, many manufacturers are developing semi-autonomous models that assist with specific tasks, such as loading, dumping, and transporting materials. Autonomous trucks can operate in challenging and remote environments, reducing the need for human operators in hazardous areas.

Remote-controlled dump trucks are also gaining popularity, allowing operators to control the vehicle from a safe distance. This capability is especially useful in mining and quarrying, where hazardous conditions are common. Remote and autonomous technology improves efficiency, reduces labor costs, and enhances safety in high-risk operations, making it a valuable investment for dump truck manufacturers.

6. Increased Focus on Lightweight Materials and Durability

Manufacturers are increasingly using lightweight, high-strength materials to improve the durability and efficiency of dump trucks. Traditional dump trucks are often heavy, resulting in higher fuel consumption and limited load capacities. By incorporating materials like aluminum and composite alloys, manufacturers can reduce the weight of the truck without compromising its strength.

These lightweight materials also improve fuel efficiency and extend the lifespan of the truck, as they are less prone to wear and corrosion. Durable materials are particularly valuable in construction and mining, where trucks endure heavy loads and challenging conditions. By focusing on lightweight yet durable materials, manufacturers create dump trucks that are both efficient and long-lasting.

7. Customizable and Versatile Designs

Customization has become a critical factor in dump truck manufacturing. Different industries have unique requirements, and customizable dump trucks allow companies to tailor the vehicle to specific tasks. Manufacturers offer a range of options, from body styles and load capacities to specialized tires and suspension systems, ensuring that each truck meets the needs of its intended application.

Versatile designs enable dump trucks to handle various tasks, such as transporting rocks, soil, and construction debris. Customizable trucks are ideal for clients who require specialized features, allowing them to maximize productivity and reduce operational costs. Manufacturers that provide customizable options are more likely to attract a broader customer base, as they can meet diverse needs across multiple industries.

8. Enhanced Suspension Systems for Comfort and Stability

The heavy-duty nature of dump trucks can make for a rough ride, especially on uneven terrain. Enhanced suspension systems are being developed to improve driver comfort and vehicle stability. Advanced suspensions absorb shocks and reduce vibrations, making it easier for operators to work long shifts without fatigue.

Improved suspension systems also enhance stability, reducing the risk of rollovers when transporting heavy loads. This trend is particularly relevant in the mining and construction industries, where trucks navigate rough and unpredictable terrains. By focusing on suspension improvements, manufacturers can provide a safer and more comfortable experience for operators.

9. Emphasis on Digital Maintenance and Predictive Maintenance Solutions

Predictive maintenance is a growing trend in dump truck manufacturing, driven by the need to reduce downtime and extend the lifespan of vehicles. Predictive maintenance systems use data analytics to monitor vehicle health, detect early signs of wear, and alert operators to potential issues. This proactive approach minimizes breakdowns and reduces the need for costly repairs.

Digital maintenance platforms enable companies to schedule maintenance based on usage patterns rather than fixed schedules. By predicting when a component is likely to fail, these systems allow fleet managers to replace parts before a breakdown occurs. Predictive maintenance improves vehicle reliability, lowers operational costs, and enhances productivity by minimizing unplanned downtime.

10. Integration of Artificial Intelligence for Improved Efficiency

Artificial intelligence (AI) is playing a significant role in the dump truck industry. AI-powered systems optimize operations by analyzing data from various sensors, including load weight, engine performance, and fuel efficiency. AI algorithms can adjust speed, monitor braking patterns, and optimize fuel usage, making the vehicle more efficient.

In addition, AI assists with route planning, identifying the most efficient paths for dump trucks to take. This reduces travel time and minimizes fuel consumption, which is particularly beneficial for large fleets. By integrating AI, manufacturers are creating smarter, more efficient dump trucks that offer improved performance and cost savings.

Real-Life Solutions and Examples

An industry leader recently developed an autonomous dump truck for mining that reduces operational costs by operating continuously without a human operator. Another company introduced a hybrid dump truck, lowering fuel costs by up to 30% while meeting stringent environmental regulations. These examples demonstrate how manufacturers are leveraging technology to provide effective solutions to modern challenges in the industry.

Actionable Tips for Dump Truck Manufacturers

- Adopt Eco-Friendly Technology: Incorporate hybrid or electric options to attract environmentally conscious clients and comply with emissions regulations.

- Offer Customizable Features: Allow customers to select from various features and configurations to meet their unique needs.

- Invest in Predictive Maintenance: Implement digital maintenance solutions to reduce downtime and extend vehicle lifespan.

- Prioritize Safety: Incorporate advanced safety features, such as collision avoidance and stability control, to attract clients focused on safety.

- Utilize AI for Efficiency: Integrate AI technology to optimize fuel consumption, route planning, and vehicle performance.

Common Questions About Dump Truck Manufacturers

Are there dump trucks that are fuel-efficient?

Yes, many manufacturers now offer fuel-efficient dump trucks with advanced engines and hybrid technology. These trucks are designed to reduce fuel consumption while maintaining high performance.

What is the benefit of autonomous dump trucks?

Autonomous dump trucks increase efficiency and safety, particularly in hazardous environments. They operate without a human driver, reducing labor costs and minimizing the risk of accidents.

Can dump trucks be customized?

Yes, many manufacturers provide customizable dump trucks, allowing clients to choose features like load capacity, suspension, and safety systems. Customization helps companies tailor trucks to specific applications.

How does predictive maintenance benefit dump trucks?

Predictive maintenance uses data to monitor vehicle health, detecting early signs of wear and allowing for timely maintenance. This reduces downtime and prevents costly breakdowns.

What materials are used in lightweight dump trucks?

Lightweight dump trucks often use materials like aluminum and composite alloys. These materials reduce weight, improve fuel efficiency, and increase durability.

Conclusion: The Future of Dump Truck Manufacturing

The dump truck manufacturing industry is evolving rapidly, driven by advancements in technology and a focus on sustainability. From fuel-efficient engines and eco-friendly designs to AI-powered systems and predictive maintenance, manufacturers are innovating to meet the demands of modern industries. The integration of automation, safety features, and customization is setting new standards for what clients expect from their heavy-duty vehicles.

As the construction and mining industries grow, the demand for efficient and reliable dump trucks will continue to rise. Manufacturers that stay ahead of these trends, prioritizing environmental responsibility, safety, and customization, will be well-positioned to succeed in the future. By adopting these advancements, dump truck companies can optimize performance, reduce operational costs, and provide superior solutions for their clients. The future of dump truck manufacturing is promising, with innovations that benefit both the industry and the environment.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices