-

Email Us

- Top Reports

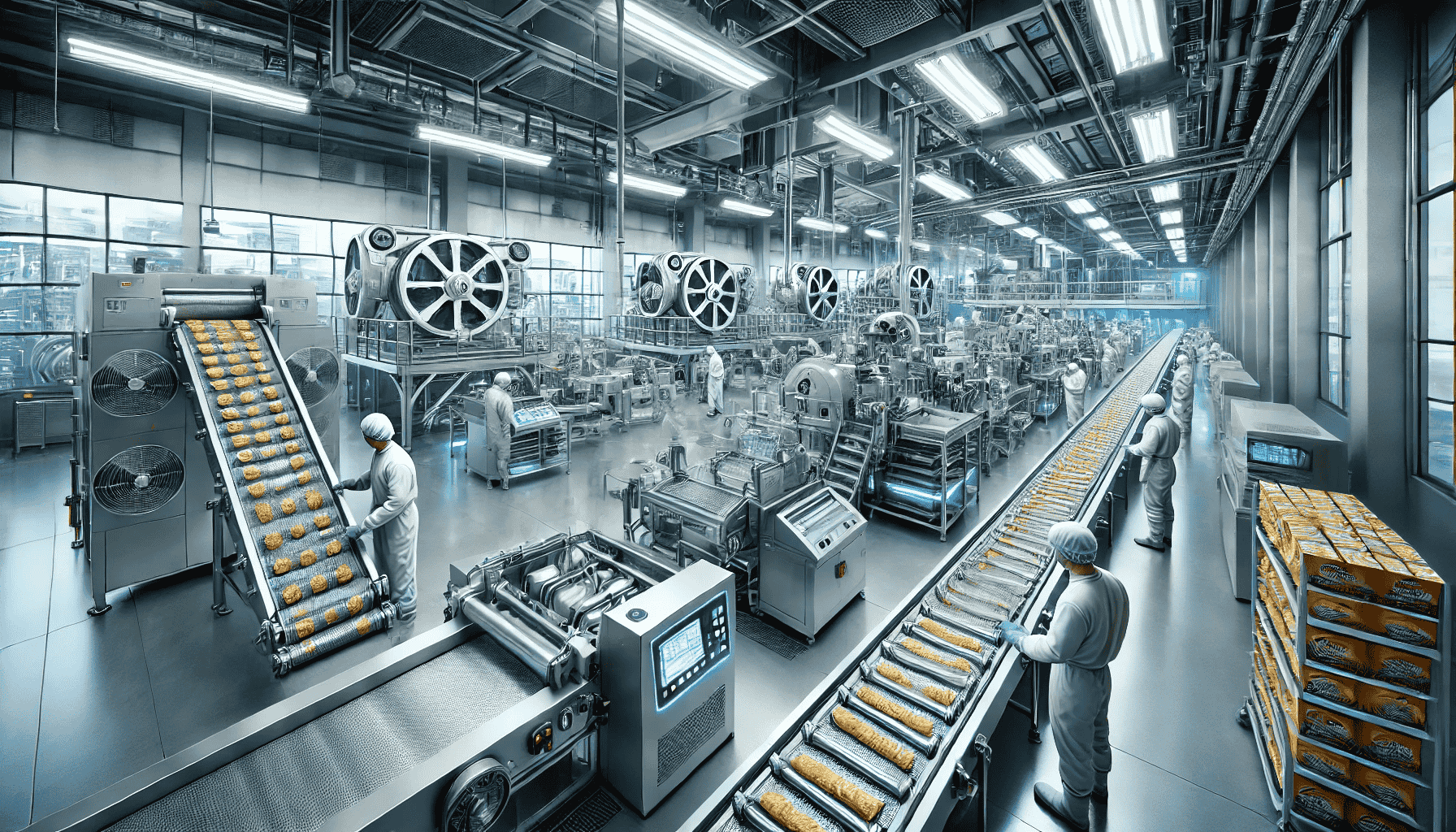

Maximizing Efficiency with Food Machinery and Industrial Solutions

Posted On 25 October, 2024

In today’s food and beverage industry, machinery and industrial solutions are at the core of modern production processes. As consumer demand grows for high-quality, sustainable, and safely processed food, businesses need to stay ahead by embracing advanced food machinery. These technologies help companies streamline their operations, reduce waste, and maintain strict quality standards, enabling them to meet both consumer expectations and regulatory requirements. In this article, we’ll explore key trends shaping the food machinery and industrial solutions market, provide guidance for businesses on optimizing production lines, and discuss how to choose the right equipment.

The Critical Role of Food Machinery in Production

Food machinery covers a wide range of equipment that is essential for the processing, packaging, and transportation of food products. From industrial mixers to advanced packaging machines, these tools are designed to automate repetitive tasks, boost efficiency, and enhance product safety. Given the complexity of modern food production, relying on manual processes alone is no longer viable for businesses that aim to scale up their operations. By integrating the right machinery into production lines, companies can significantly reduce operational costs while improving productivity and maintaining high safety standards.

In a fast-paced industry where innovation is key, businesses that adapt to technological advancements will be better positioned to meet the ever-changing demands of the market. Whether a company is focused on food processing, packaging, or waste management, choosing the right industrial solutions is critical to staying competitive and ensuring long-term success.

Now Get Sample PDF Report on : Food Machinery Grease Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=246146

Top 10 Trends in Food Machinery and Industrial Solutions

The food machinery and industrial solutions market is evolving rapidly, driven by technological innovations, shifting consumer preferences, and a growing focus on sustainability. Below, we explore the top 10 trends that are transforming the industry and how businesses can leverage these advancements to enhance their operations.

1. Automation and Robotics in Food Processing (300 words)

Automation and robotics are revolutionizing the food processing industry by streamlining tasks that were previously performed manually. Automated systems can now handle everything from ingredient mixing to packaging, dramatically increasing efficiency and reducing the risk of human error. One of the key benefits of automation is its ability to operate continuously, without the fatigue or inconsistency associated with human labor. This ensures that production lines can run at optimal capacity, leading to faster turnaround times and higher output.

Robotic systems are particularly useful in tasks that require precision and consistency, such as slicing, dicing, or packaging. For instance, robots equipped with vision systems can sort products based on size, shape, or color, ensuring that only high-quality items make it to the packaging stage. This level of precision is crucial in industries where uniformity is key, such as in baked goods or processed meats.

Moreover, the integration of robotics allows businesses to easily adapt to changes in consumer demand. With flexible robotic systems, production lines can be reconfigured to accommodate new product types or packaging designs, reducing the need for costly equipment overhauls. Automation also plays a significant role in enhancing food safety, as it minimizes the amount of human contact with food, reducing the risk of contamination.

As technology continues to evolve, the cost of automation is becoming more accessible for businesses of all sizes. Small and medium-sized enterprises (SMEs) that once found automation out of reach are now able to invest in these systems, leveling the playing field in the competitive food processing market. Ultimately, automation and robotics are not just trends—they are quickly becoming the standard for food production, helping companies increase efficiency, improve product quality, and reduce costs.

2. IoT-Enabled Smart Machines (300 words)

The Internet of Things (IoT) has made a significant impact on food machinery by enabling smart machines that collect and transmit data in real-time. These IoT-enabled machines can monitor various parameters of the production process, such as temperature, pressure, and humidity, ensuring that the production environment remains optimal at all times. The ability to gather and analyze data in real-time helps businesses identify inefficiencies, track machine performance, and schedule maintenance before breakdowns occur.

For instance, an IoT-enabled mixer in a food processing plant can track how efficiently ingredients are being mixed and send an alert if adjustments are needed to maintain product consistency. Additionally, by analyzing historical data, businesses can predict when a machine is likely to require maintenance, allowing them to address issues proactively rather than reactively. This predictive maintenance reduces downtime, which is a significant cost-saving factor for any production line.

Smart machines are also capable of integrating with other systems, such as enterprise resource planning (ERP) software or supply chain management tools. This integration provides companies with a holistic view of their operations, allowing them to make more informed decisions. For example, a food manufacturer could automatically adjust production levels based on real-time data from its supply chain, ensuring that production matches demand and minimizing waste.

The use of IoT-enabled machinery is particularly beneficial for companies aiming to achieve Industry 4.0 standards, which focus on smart automation, real-time data exchange, and machine-to-machine communication. As more businesses adopt IoT technologies, they can expect greater transparency, improved efficiency, and enhanced operational control across their production lines.

3. Sustainability and Energy Efficiency (300 words)

Sustainability is no longer a buzzword—it’s a critical business objective for companies across the food and beverage industry. As consumers become more eco-conscious, they expect the businesses they support to adopt environmentally friendly practices. One of the key areas where companies can reduce their environmental impact is through the use of energy-efficient machinery.

Energy-efficient food machinery is designed to minimize power consumption while maintaining or even improving production efficiency. For instance, newer models of industrial food mixers and packaging machines use advanced motor technologies that consume less electricity without compromising on performance. This not only helps businesses reduce their carbon footprint but also results in significant cost savings in the long term.

Water conservation is another important aspect of sustainability in food machinery. Many machines, such as food washers or beverage fillers, have been re-engineered to use less water during cleaning and processing. For example, closed-loop water systems recycle and purify water for reuse in the production process, drastically reducing water waste.

Additionally, energy-efficient machines often come equipped with sensors that monitor energy use and automatically shut off when not in use. This feature prevents energy from being wasted during downtime, further contributing to cost savings and sustainability goals.

Governments and regulatory bodies are also pushing for stricter environmental standards, and energy-efficient machinery can help companies comply with these regulations. Businesses that invest in sustainable technology not only benefit from lower operational costs but also position themselves as environmentally responsible, which can enhance their reputation and attract eco-conscious consumers.

4. Modular and Scalable Machinery (300 words)

Modular and scalable machinery is a growing trend in the food processing industry, offering flexibility to businesses that need to adapt quickly to changes in production requirements. Unlike traditional machinery, which often needs to be replaced as production capacity increases, modular machines allow companies to add or remove components based on their specific needs.

For example, a food manufacturer producing frozen meals might start with a basic line that includes mixing and packaging equipment. As demand grows, the company could add additional freezing or sealing modules to increase capacity without replacing the entire production line. This modular approach is highly cost-effective, especially for SMEs that need to scale operations without significant capital investment.

Scalability is particularly important in today’s fast-changing food market, where trends and consumer preferences can shift quickly. Companies that invest in scalable machinery can pivot more easily to meet new demands, whether that means increasing production capacity or adding new product lines. For instance, during the COVID-19 pandemic, many food manufacturers quickly shifted their focus from foodservice products to packaged goods for retail, a change that would have been more challenging without scalable equipment.

Another advantage of modular machines is that they are often easier to maintain. Since each module operates independently, businesses can perform maintenance on one part of the system without shutting down the entire production line. This reduces downtime and ensures that production remains uninterrupted, even when maintenance is required.

Overall, modular and scalable machinery offers businesses the flexibility to grow and adapt without incurring the high costs and disruptions associated with replacing or overhauling entire systems. This trend is likely to continue as companies seek ways to remain agile and responsive to market changes.

5. Enhanced Food Safety (300 words)

Food safety remains a top priority for manufacturers, and advances in food machinery are helping businesses meet stringent regulatory requirements while minimizing contamination risks. Enhanced food safety features are being built into the design of industrial food machinery, ensuring that the equipment itself does not contribute to foodborne illnesses or other safety concerns.

One key area of focus is the design of machines that are easy to clean and sanitize. Machines used in food production must meet high hygiene standards, and equipment that is difficult to clean can harbor bacteria or other pathogens. Modern food machinery is designed with fewer crevices and smooth surfaces that prevent food particles from becoming trapped, making them easier to clean and reducing the risk of contamination.

Another important trend in food safety is the use of materials that are both durable and non-toxic. Food-grade stainless steel, for example, is commonly used in machinery because it resists corrosion, does not react with food, and is easy to sanitize. Additionally, antimicrobial coatings are being applied to machine surfaces to inhibit the growth of bacteria.

Automation also plays a significant role in enhancing food safety. Automated systems reduce the amount of human contact with food products, which lowers the risk of contamination. For instance, robotic arms can be used to handle food items during packaging, ensuring that products are not exposed to the germs or bacteria that might be transferred by human workers.

Finally, the integration of real-time monitoring systems in food machinery allows businesses to track critical safety parameters such as temperature and humidity. If any deviations occur, the system can automatically trigger corrective actions, such as adjusting the temperature or shutting down the machine to prevent unsafe products from reaching consumers. This proactive approach to food safety ensures that manufacturers can quickly respond to potential hazards, protecting both their reputation and the health of their customers.

6. Multi-Functional Machines (300 words)

In an industry where space and resources are often at a premium, multi-functional machines are gaining popularity. These machines are designed to perform a variety of tasks, such as mixing, processing, and packaging, making them an invaluable asset for companies that need to maximize efficiency without sacrificing quality.

One example of a multi-functional machine is a combination mixer and extruder, which can blend ingredients and form them into a specific shape or texture in a single process. This not only saves time but also reduces the need for multiple pieces of equipment, freeing up valuable space on the production floor.

Multi-functional machines are especially beneficial for businesses that produce a wide range of products. Instead of purchasing separate machines for each process, companies can invest in one versatile machine that can be reconfigured to handle different tasks. This flexibility is crucial for businesses that need to adapt to changing consumer demands or introduce new products to the market.

Another advantage of multi-functional machines is that they often come with programmable settings that allow operators to switch between different functions quickly. For instance, a machine used to package dry goods could be adjusted to handle liquids with a simple reconfiguration, enabling businesses to produce a variety of products without lengthy changeovers.

For smaller companies, multi-functional machines can be a game-changer, as they allow businesses to compete with larger manufacturers without the need for extensive capital investment in multiple machines. By investing in equipment that can perform multiple tasks, businesses can streamline their operations, reduce costs, and increase productivity, all while maintaining high standards of quality and safety.

7. Advanced Packaging Solutions (300 words)

Packaging is a critical aspect of food production, and advances in packaging technology are helping businesses extend product shelf life, reduce waste, and enhance sustainability. High-speed packaging machines that use environmentally friendly materials are becoming increasingly popular, as businesses seek to meet consumer demand for sustainable products while improving operational efficiency.

One of the most notable trends in packaging is the shift towards biodegradable and recyclable materials. Many food packaging machines are now designed to work with eco-friendly materials, such as compostable plastics or recyclable paper, without compromising on the durability or protective qualities of the packaging. This not only reduces the environmental impact of packaging waste but also aligns with consumer preferences for sustainable products.

In addition to sustainability, speed and precision are key concerns in modern packaging. High-speed packaging machines can package thousands of units per hour, ensuring that products are sealed and ready for distribution in record time. These machines are often equipped with sensors that ensure each package is filled and sealed correctly, reducing the risk of product spoilage or contamination.

Modified atmosphere packaging (MAP) is another advanced solution that is gaining traction in the food industry. MAP machines replace the air inside a package with a gas mixture that helps preserve the freshness of the food for a longer period. This technology is particularly useful for perishable goods like fresh produce, meats, and dairy products, which require extended shelf life without the use of artificial preservatives.

Overall, advances in packaging technology are enabling businesses to improve the quality and longevity of their products, reduce their environmental footprint, and enhance the overall efficiency of their operations. By investing in cutting-edge packaging solutions, companies can meet both consumer and regulatory demands while staying ahead in a competitive market.

8. Customization and Flexibility (300 words)

Customization and flexibility in food machinery are becoming increasingly important as consumer preferences shift and product diversification becomes the norm. Companies that can quickly adapt their production lines to accommodate new products or packaging types have a significant advantage in the marketplace. As a result, machinery manufacturers are focusing on creating equipment that is not only highly efficient but also customizable to meet the unique needs of different businesses.

For example, some food manufacturers require machines that can switch between producing large and small batches without losing efficiency. Others may need machinery that can handle different packaging materials, from plastic to glass or biodegradable options. Customizable machinery allows businesses to modify their production lines to suit these varied needs without having to invest in new equipment every time a change is required.

Another aspect of flexibility is the ability to produce multiple product types on the same production line. This is particularly useful for companies that want to offer a diverse product range without the cost of maintaining separate production lines for each item. For instance, a company that produces both dry snacks and beverages could use the same machinery to handle both types of products with minimal adjustments.

In addition to product flexibility, customizable machinery can also accommodate changes in packaging design. With consumer preferences constantly evolving, businesses must be able to adapt their packaging to reflect new trends or branding changes. Machinery that can be quickly reconfigured to handle different packaging shapes, sizes, and materials ensures that businesses can stay agile in a competitive market.

The trend toward customization and flexibility in food machinery is likely to continue as businesses seek to meet the growing demand for personalized and diverse products. By investing in adaptable equipment, companies can remain competitive, reduce downtime, and improve overall operational efficiency.

9. Waste Management Technology (300 words)

Food waste is a significant issue in the food and beverage industry, with many businesses looking for ways to reduce their environmental impact while maintaining profitability. Waste management technology is playing a crucial role in helping companies manage and minimize food waste throughout the production process. From food waste disposal machines to recycling technologies, businesses are increasingly adopting solutions that not only reduce waste but also turn it into valuable resources.

One of the most innovative waste management technologies is the food waste digester, which breaks down organic waste into compost or biogas. These machines are designed to handle large volumes of food waste, making them ideal for large-scale production facilities. By converting food waste into renewable energy or compost, companies can reduce their environmental footprint and lower disposal costs.

Another key trend is the use of food waste recycling systems that separate organic waste from non-recyclable materials. These systems help businesses streamline their waste disposal processes and ensure that recyclable materials are not sent to landfills. Some recycling technologies even allow businesses to repurpose food waste into animal feed or other useful products, further reducing waste and creating new revenue streams.

In addition to waste disposal, machinery that minimizes food waste during production is becoming more common. For example, precision cutting machines ensure that food products are cut with minimal waste, while portioning systems help businesses control serving sizes and reduce overproduction. By investing in waste reduction technologies, companies can not only meet sustainability goals but also improve operational efficiency and reduce costs.

As environmental regulations become stricter and consumer demand for sustainable practices grows, businesses that adopt advanced waste management technology will be better positioned to succeed in the market. Reducing food waste is not just an ethical imperative—it’s also a smart business strategy that can lead to significant cost savings and improved brand reputation.

10. Compact and Space-Saving Equipment (300 words)

As production facilities become more crowded and businesses look to maximize their use of space, compact and space-saving equipment is gaining popularity in the food processing industry. Compact machinery is designed to deliver the same level of efficiency and performance as larger equipment but in a smaller footprint, making it ideal for businesses with limited floor space.

One of the main advantages of compact equipment is its ability to fit into existing production lines without requiring significant modifications to the layout. This allows businesses to add new capabilities or increase production capacity without having to expand their facilities. For example, a compact industrial mixer or packaging machine can be installed in a small space, providing the same level of performance as a larger machine but with a much smaller footprint.

Another benefit of compact machinery is that it often requires less energy and fewer resources to operate. This makes it a cost-effective solution for businesses looking to reduce their operational expenses without sacrificing productivity. Compact machines are also easier to maintain, as they typically have fewer components and are designed for quick and easy cleaning.

In addition to being space-saving, many compact machines are also designed with portability in mind. This allows businesses to move equipment as needed, providing greater flexibility in production. For example, a compact food processing machine can be moved between different production lines or even different facilities, allowing businesses to adjust their operations based on demand.

Overall, the trend toward compact and space-saving equipment is likely to continue as businesses seek to optimize their use of space and resources. By investing in machinery that delivers high performance in a small footprint, companies can improve their operational efficiency and remain competitive in a crowded market.

How the Food Machinery and Industrial Solutions Market is Changing the Industry

The rapid advancements in food machinery and industrial solutions have had a profound impact on the food and beverage industry. By reducing manual labor and improving automation, these technologies have enabled businesses to streamline their operations, reduce costs, and improve product quality. Additionally, the shift towards sustainability has driven the development of energy-efficient machinery, allowing companies to meet both regulatory requirements and consumer expectations for eco-friendly practices.

Smart technology has also played a significant role in transforming the industry. IoT-enabled machines provide real-time data on production performance, allowing businesses to make informed decisions and optimize their operations. This has led to greater transparency, improved efficiency, and reduced downtime.

The role of food machinery and industrial solutions in modern food production is more important than ever. By staying up to date with the latest trends and investing in advanced technologies, businesses can improve their operational efficiency, reduce waste, and meet the evolving demands of consumers and regulators. From automation and robotics to energy-efficient machinery and waste management solutions, the future of food production is being shaped by innovation. Businesses that embrace these trends will be well-positioned to succeed in an increasingly competitive market.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices