-

Email Us

- Top Reports

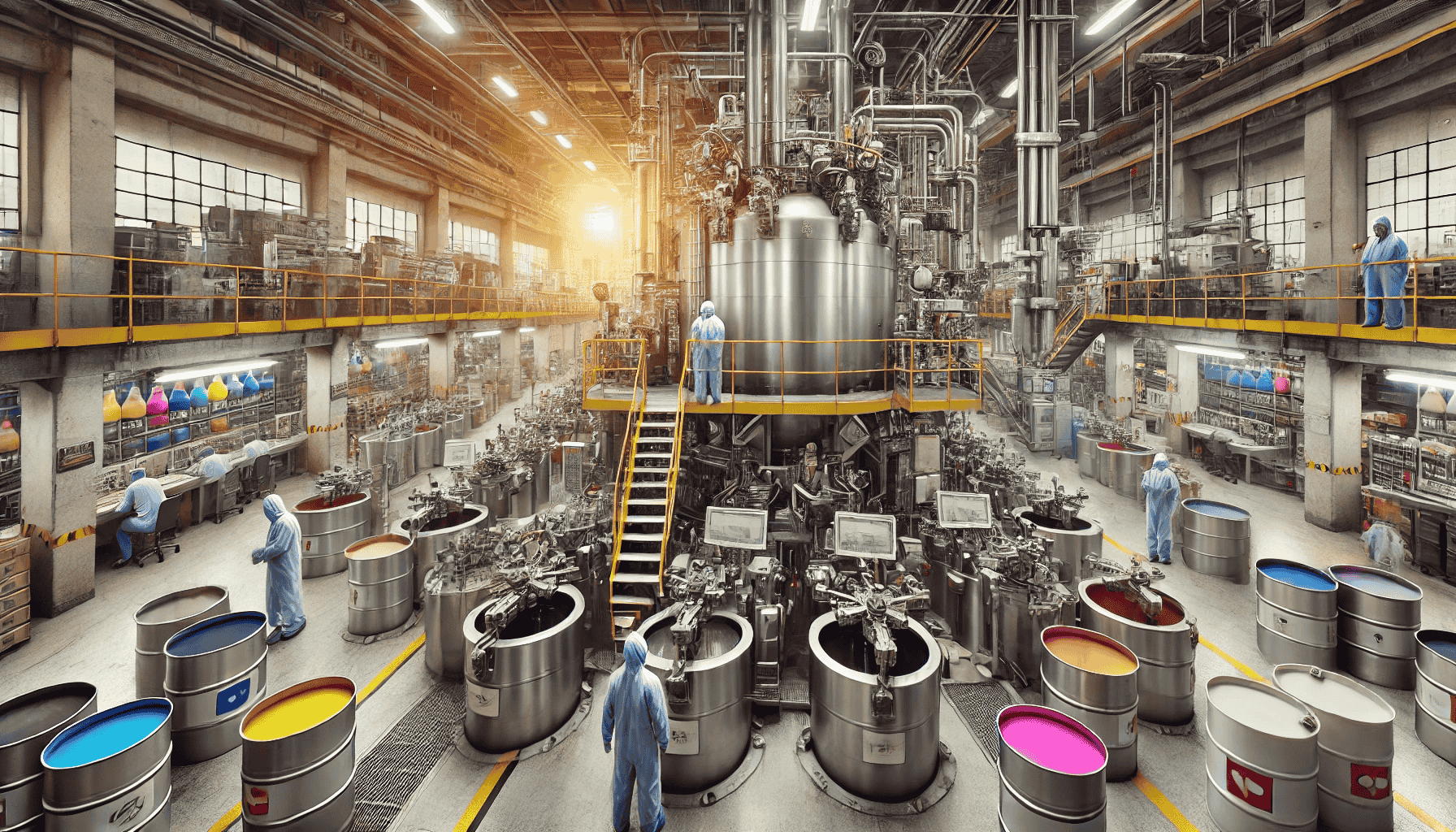

Innovations and Key Trends Shaping the Printing Ink Manufacturing Industry

Posted On 23 October, 2024

Introduction

Printing ink manufacturers are at the heart of numerous industries, from packaging and publishing to textiles and electronics. As technology evolves, so does the demand for innovative printing ink solutions that meet the changing needs of businesses and consumers alike. Today, the printing ink manufacturing sector is witnessing rapid transformations driven by sustainability, digitalization, and advancements in technology. This blog delves into the key trends, technologies, and innovations reshaping the printing ink manufacturing industry and offers insights into how businesses can capitalize on these changes for growth.

Now Get Sample PDF Report on : Printing Ink Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=161595

Key Trends in Printing Ink Manufacturing

1. Shift Toward Eco-Friendly and Sustainable Inks

Environmental sustainability is one of the most pressing concerns for industries today, and printing ink manufacturing is no exception. Increasingly, manufacturers are developing eco-friendly inks that reduce environmental impact. These inks are derived from renewable resources, such as vegetable-based oils, soy, and water, as opposed to traditional petroleum-based inks.

This shift is driven by consumer demand for greener products and regulatory pressures to reduce the environmental footprint of manufacturing processes. Companies like Sun Chemical and Flint Group have introduced sustainable ink solutions that minimize volatile organic compounds (VOCs) and ensure safer disposal.

Eco-friendly inks are also gaining traction in packaging, where brands are striving for sustainability throughout their supply chains. This trend will continue to grow as more businesses seek to align with sustainability goals and consumer expectations.

2. Advancements in Digital Printing Technology

The rise of digital printing technology has revolutionized the printing industry. Unlike traditional offset printing, digital printing offers more flexibility, allowing manufacturers to produce shorter print runs with faster turnaround times. This has opened up opportunities for personalization and customization, which are particularly important in sectors such as packaging, marketing, and textiles.

Inkjet printing technology, in particular, has made significant strides, with advancements in ink formulation that improve print quality, adhesion, and durability. UV-curable inks have become popular due to their fast-drying properties and ability to print on a wide range of substrates, including plastics, glass, and metals.

As digital printing continues to evolve, printing ink manufacturers are focusing on developing inks that are compatible with these technologies. This trend is expected to drive further innovation, enabling more efficient and cost-effective printing solutions for businesses.

3. Growth in Packaging Inks and Food-Safe Solutions

The packaging industry is one of the largest consumers of printing inks, and with the growth of e-commerce and demand for packaged goods, this sector continues to expand. However, packaging inks now require greater scrutiny due to food safety concerns. Inks used in food packaging must comply with stringent regulations to ensure they do not contaminate the food products they contain.

Printing ink manufacturers are responding by developing low-migration inks, which prevent harmful chemicals from migrating from the ink to the food. These inks are formulated using safe, non-toxic ingredients that meet regulatory standards for food safety.

As more businesses focus on food packaging, manufacturers that prioritize food-safe printing inks will find increasing demand from both food producers and regulatory bodies.

4. Innovations in Conductive Inks for Electronics

Conductive inks are a fast-growing segment in the printing ink market, particularly in the field of electronics. These inks contain materials like silver, carbon, or copper that allow them to conduct electricity, making them ideal for use in printed electronics, such as touchscreens, sensors, and RFID tags.

Manufacturers are developing conductive inks that are more efficient, cost-effective, and versatile, enabling the production of flexible electronics that can be integrated into everyday products. Companies like DuPont and Henkel are leaders in this space, offering conductive ink solutions that cater to the growing demand for wearable technology, smart packaging, and the Internet of Things (IoT).

As the electronics industry continues to expand, the demand for conductive inks will likely increase, offering printing ink manufacturers a lucrative growth opportunity.

5. Demand for UV-Curable Inks

UV-curable inks have gained popularity due to their versatility and environmental benefits. These inks dry instantly when exposed to ultraviolet (UV) light, eliminating the need for solvents and reducing VOC emissions. UV-curable inks also offer excellent adhesion to a variety of substrates, making them suitable for printing on non-porous surfaces like plastics, metals, and glass.

In addition to their environmental advantages, UV-curable inks provide enhanced durability, scratch resistance, and color vibrancy, which are highly desirable in industries such as packaging, textiles, and outdoor advertising.

With the increasing focus on sustainability and efficiency, UV-curable inks are becoming the go-to solution for many printing applications, and manufacturers that invest in UV-curable technologies will likely see continued demand for these products.

6. Personalization and Customization in Printing

The demand for personalized products is rising across industries, particularly in packaging and promotional materials. Digital printing technologies have made it possible to create customized products quickly and affordably, and printing ink manufacturers are adapting by developing inks that support these needs.

Personalized packaging, such as custom labels and limited-edition designs, is a growing trend, driven by the desire for unique consumer experiences. Printing ink manufacturers are producing inks that work seamlessly with digital printers to enable high-quality, on-demand printing for customized designs.

This trend toward personalization is not only reshaping the way businesses approach printing but also driving innovation in ink formulations to ensure consistent quality and color accuracy across customized products.

7. Water-Based Inks and the Push for Non-Toxic Alternatives

Water-based inks are becoming increasingly popular as industries move away from solvent-based inks that contain harmful chemicals. These inks, which use water as the primary solvent, are less toxic, emit fewer VOCs, and are safer for both workers and the environment.

Water-based inks are particularly favored in packaging, textiles, and labels, where safety and environmental concerns are top priorities. They offer excellent print quality and adhesion, making them suitable for a variety of applications, from food packaging to clothing tags.

As regulatory bodies push for stricter environmental standards, water-based inks are expected to become the industry standard, with manufacturers focusing on improving their performance and versatility.

8. Integration of Smart Inks in Packaging and Labels

Smart inks, which change color or react to external stimuli like temperature, light, or pressure, are gaining attention for their applications in packaging and labeling. These inks offer added functionality, such as indicating product freshness, authenticity, or tampering.

In the pharmaceutical and food industries, smart inks can be used to create packaging that changes color when the product is exposed to certain conditions, such as heat or humidity. This technology not only enhances product safety but also provides valuable information to consumers.

As the demand for smart packaging grows, printing ink manufacturers are exploring innovative ways to incorporate these inks into everyday products, offering new possibilities for interactive and intelligent packaging solutions.

9. Sustainability in Ink Packaging and Production

In addition to creating sustainable ink formulations, manufacturers are also focusing on making the packaging and production processes more eco-friendly. Biodegradable packaging for inks, reducing energy consumption in manufacturing facilities, and minimizing waste are becoming key priorities for responsible manufacturers.

Some companies are adopting closed-loop recycling systems, where used ink cartridges and containers are collected, recycled, and reused, reducing the environmental impact of packaging materials. By adopting more sustainable practices, printing ink manufacturers can meet the growing demand for environmentally responsible products and production methods.

10. Expansion of the Global Market and Growth in Emerging Economies

The global market for printing inks is expanding, particularly in emerging economies in Asia, Latin America, and Africa. As industrialization continues to grow in these regions, the demand for printing inks in packaging, publishing, and textiles is increasing. This presents significant opportunities for manufacturers looking to expand their market presence.

In particular, countries like China and India are seeing a surge in demand for packaging inks as e-commerce continues to grow. Printing ink manufacturers that invest in these emerging markets by establishing local production facilities or partnerships will be well-positioned to capitalize on the growing demand.

Value Addition: Real-Life Solutions for Businesses

For printing ink manufacturers, focusing on sustainability and innovation is essential for growth in today’s market. One solution is to develop biodegradable inks and packaging materials to meet regulatory requirements and satisfy consumer demand for eco-friendly products. Offering inks that are compatible with digital printing technology can also help manufacturers tap into the expanding market for personalized products.

Another real-life example is the use of conductive inks in the electronics industry. By collaborating with electronics manufacturers, printing ink companies can develop custom conductive inks that meet the specific needs of their clients, from flexible circuits to smart packaging.

Actionable Tips for Businesses

- Invest in Sustainability: Focus on developing eco-friendly inks and reducing the environmental impact of your manufacturing processes. Consumers and businesses are increasingly prioritizing sustainability, and meeting these demands can differentiate your products.

- Embrace Digital Printing: Ensure that your inks are compatible with the latest digital printing technologies, which offer greater flexibility and cost-efficiency. This will enable you to cater to industries that require short print runs and customization.

- Develop Food-Safe Inks: For companies working in the packaging sector, investing in food-safe inks is essential to comply with regulatory standards and ensure product safety. Low-migration inks are a must for food and beverage packaging.

- Explore Emerging Markets: Expand your presence in emerging economies where industrialization is driving demand for printing inks. Establishing partnerships or local production facilities in these regions can help you capture new opportunities.

Frequently Asked Questions (FAQs)

- What are eco-friendly inks? Eco-friendly inks are inks made from renewable resources, such as vegetable oils or water, which reduce environmental impact by emitting fewer volatile organic compounds (VOCs).

- Why are digital printing technologies important? Digital printing allows for faster, more flexible printing with shorter print runs and customization options. It also eliminates the need for traditional printing plates, making it more cost-effective.

- What are low-migration inks? Low-migration inks are specially formulated to prevent harmful chemicals from transferring from the ink to the food, ensuring compliance with food safety regulations.

- How do conductive inks work? Conductive inks contain materials like silver or carbon that allow them to conduct electricity, making them suitable for use in printed electronics, such as sensors and RFID tags.

The printing ink manufacturing industry is undergoing significant transformation, driven by trends such as sustainability, digitalization, and advancements in technology. As businesses seek more efficient, eco-friendly, and versatile printing solutions, manufacturers must innovate to stay competitive. By focusing on sustainable practices, embracing digital printing, and exploring new markets and technologies, printing ink manufacturers can position themselves for long-term success.

Looking to the future, the demand for eco-friendly inks, smart technologies, and personalized printing solutions is set to grow. Manufacturers that stay ahead of these trends and invest in innovation will not only meet the changing needs of the market but also play a pivotal role in shaping the future of the printing industry.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices