-

Email Us

- Top Reports

The Future of Mining Equipment Manufacturers in the USA: Trends, Insights, and Opportunities

Posted On 22 October, 2024

Introduction

Mining equipment manufacturers play a crucial role in the mining industry by providing the tools and machinery required for efficient extraction, processing, and transportation of valuable minerals and resources. In the United States, these manufacturers are at the forefront of technological advancements and are continuously evolving to meet the challenges of sustainability, safety, and efficiency in the industry. As the global demand for minerals continues to rise, mining equipment manufacturers in the USA are leveraging new technologies and strategies to stay competitive in an ever-changing landscape. This blog explores the key trends shaping the industry, delves into emerging innovations, and provides actionable insights for businesses to optimize their growth.

Now Get Sample PDF Report on : Mining Equipment Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=276523

Key Trends in Mining Equipment Manufacturing

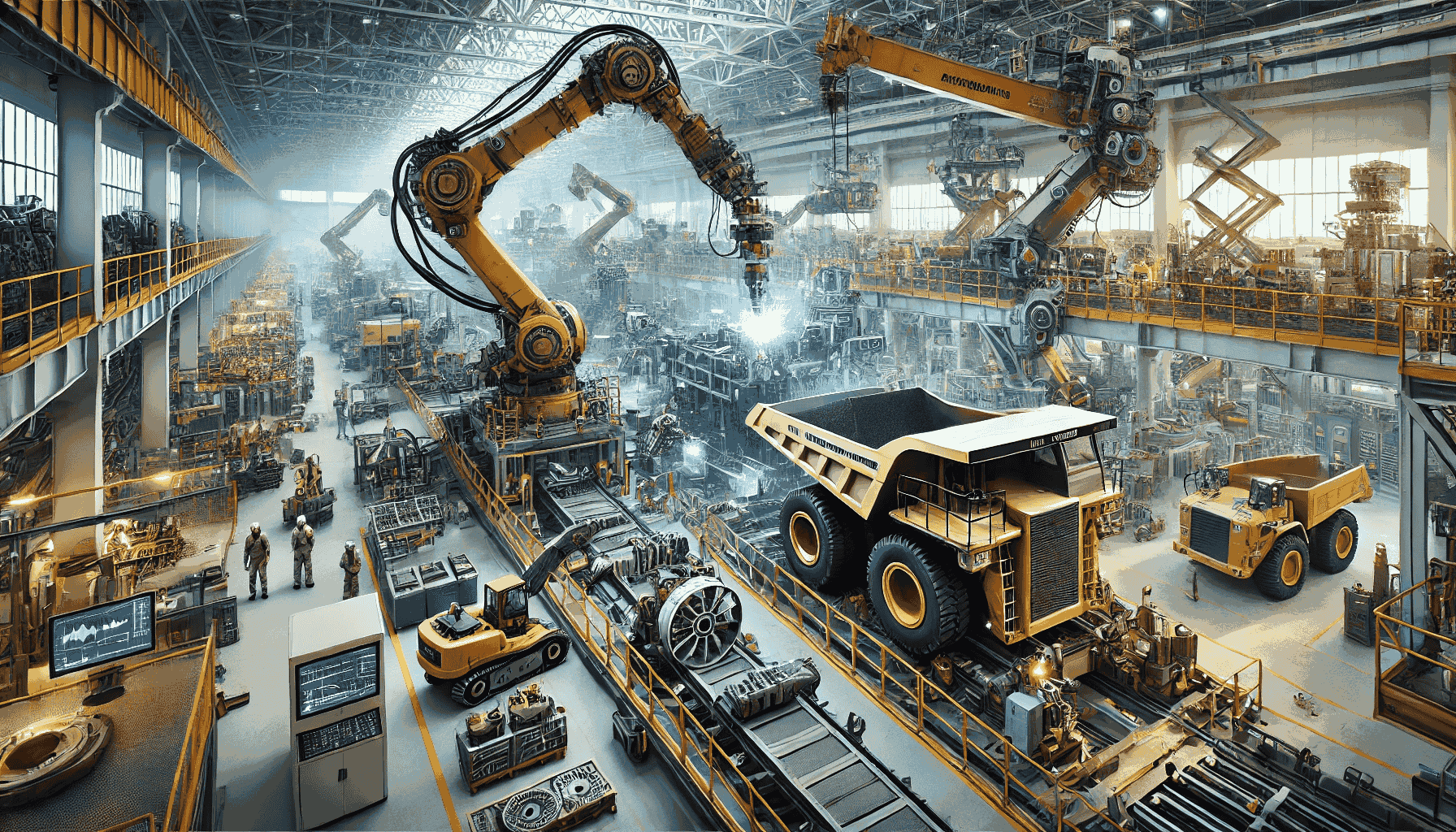

1. Adoption of Automation and Robotics

One of the most significant trends in the mining equipment industry is the growing adoption of automation and robotics. Automation allows mining companies to enhance efficiency, reduce human error, and improve safety in high-risk environments. Autonomous vehicles, drilling machines, and robotic systems are becoming more prevalent in mining operations, as they can work continuously, even in hazardous conditions.

Manufacturers like Caterpillar and Komatsu have been at the forefront of developing autonomous haul trucks and remote-controlled machines. These innovations allow for improved productivity by reducing downtime and minimizing the need for manual labor. As automation technology becomes more advanced, mining equipment manufacturers in the USA will continue to play a critical role in reshaping the future of mining.

2. Focus on Sustainability and Energy Efficiency

The mining industry is facing increasing pressure to reduce its environmental impact. As a result, mining equipment manufacturers are focusing on creating machines that are more energy-efficient and environmentally friendly. Innovations such as electric-powered mining equipment, hybrid systems, and fuel-efficient machinery are becoming more widespread.

For example, electric mining trucks and loaders are gaining popularity due to their ability to reduce emissions and lower operating costs. These machines contribute to sustainability efforts by decreasing reliance on fossil fuels and cutting down greenhouse gas emissions. Mining equipment manufacturers that prioritize sustainability will not only meet regulatory requirements but also gain a competitive edge in the market by appealing to environmentally conscious mining companies.

3. Digitalization and Data-Driven Solutions

The digital transformation of the mining industry has brought significant changes to the way equipment is monitored, maintained, and operated. Data-driven solutions, such as predictive maintenance and real-time monitoring, are being integrated into mining equipment to optimize performance and prevent costly downtime. Sensors and Internet of Things (IoT) technology allow operators to track equipment conditions in real-time, enabling them to make informed decisions and take preventative actions.

Digital twins, which are virtual replicas of physical mining equipment, are another emerging technology. They enable manufacturers and operators to simulate different scenarios and optimize equipment performance. The incorporation of data analytics into mining equipment manufacturing is revolutionizing the way companies approach equipment maintenance and operational efficiency.

4. Safety Innovations in Equipment Design

Safety is a top priority in the mining industry, and equipment manufacturers in the USA are continuously innovating to improve safety features in their products. From advanced braking systems and collision avoidance technology to remote-controlled machinery, safety enhancements are becoming a standard feature in mining equipment.

One such example is the implementation of proximity detection systems, which use sensors to detect objects and people near the equipment, preventing accidents. These systems are especially crucial in underground mining operations, where visibility and maneuverability can be challenging. By incorporating safety innovations, manufacturers help reduce workplace accidents, improve regulatory compliance, and protect workers in hazardous environments.

5. 3D Printing and Additive Manufacturing

3D printing, also known as additive manufacturing, is revolutionizing the way mining equipment parts are produced. This technology allows manufacturers to create custom components quickly and efficiently, reducing lead times and costs associated with traditional manufacturing methods. 3D printing is particularly beneficial for producing replacement parts in remote locations, where supply chain challenges can delay equipment repairs.

Companies like Sandvik have already begun using 3D printing to produce mining equipment parts, including drill bits and cutting tools. As 3D printing technology advances, its applications in the mining industry will likely expand, allowing manufacturers to offer more flexible and cost-effective solutions to their customers.

6. Collaboration with Mining Companies for Custom Solutions

Mining equipment manufacturers are increasingly working closely with mining companies to develop custom solutions that meet specific operational needs. By collaborating with clients, manufacturers can design and build equipment tailored to the unique challenges of each mine, whether it be a specific type of ore, terrain, or environmental concern.

This trend towards customization is helping companies optimize their equipment performance and improve efficiency. It also strengthens relationships between manufacturers and mining companies, as both parties work together to achieve mutually beneficial outcomes. Custom-built equipment can provide mining companies with a competitive advantage, while manufacturers can differentiate themselves by offering personalized solutions.

7. Growth in Underground Mining Equipment

As surface-level mineral deposits become depleted, there is a growing need for underground mining operations. This shift has increased the demand for specialized underground mining equipment, such as tunnel boring machines, roof bolters, and ventilation systems. Underground mining presents unique challenges, including confined spaces, poor ventilation, and the need for precise excavation techniques.

Manufacturers like Epiroc and Sandvik are leaders in the production of underground mining equipment, offering solutions that improve safety and efficiency in challenging conditions. As underground mining continues to grow, manufacturers that specialize in this equipment will be in high demand.

8. Rise of Electric and Battery-Powered Equipment

The shift towards electrification is another major trend in the mining equipment industry. Battery-powered machines are becoming more popular due to their lower environmental impact, reduced operating costs, and quieter operation compared to traditional diesel-powered equipment. This shift aligns with the broader industry goal of reducing greenhouse gas emissions and improving sustainability.

Battery-powered equipment is particularly well-suited for underground mining, where ventilation is limited and reducing emissions is critical for worker safety. Major manufacturers like Caterpillar and Sandvik have developed electric mining trucks and loaders that offer improved performance while minimizing environmental impact. As the demand for electric mining equipment grows, manufacturers that invest in this technology will lead the way in creating a cleaner, more sustainable future for mining.

9. Expansion of Rental and Leasing Services

With the high cost of mining equipment, many companies are opting to rent or lease equipment rather than make large capital investments. This trend has led to an expansion of rental and leasing services offered by equipment manufacturers and distributors. Rental services provide mining companies with flexibility, allowing them to use the latest equipment without committing to long-term ownership.

This model is particularly attractive for smaller mining operations or companies that require specialized equipment for short-term projects. By offering rental and leasing options, manufacturers can tap into a broader market and meet the varying needs of their clients.

10. Focus on Supply Chain Resilience and Local Manufacturing

The COVID-19 pandemic highlighted the vulnerabilities in global supply chains, particularly for industries like mining that rely on complex logistics networks. In response, many mining equipment manufacturers in the USA are focusing on building more resilient supply chains by increasing local production and reducing reliance on overseas suppliers.

Local manufacturing helps ensure that equipment and parts are available when needed, minimizing delays and reducing transportation costs. By investing in domestic production capabilities, manufacturers can improve their responsiveness to market demand and enhance customer satisfaction.

Value Addition: Real-Life Solutions for Businesses

For mining equipment manufacturers, staying competitive means embracing innovation and focusing on customer needs. One real-life solution is offering predictive maintenance systems as part of the equipment package. By using IoT sensors to monitor equipment health, companies can offer maintenance services that prevent costly breakdowns, improving customer satisfaction and loyalty.

Another example is developing modular equipment that can be easily adapted to different mining conditions. Modular designs allow mining companies to customize equipment based on their specific needs, making it easier to scale operations and reduce downtime.

Actionable Tips for Businesses

- Invest in Automation: Automation is the future of mining. Investing in autonomous equipment will not only improve operational efficiency but also help mining companies reduce labor costs and improve safety.

- Embrace Sustainability: Focus on producing energy-efficient and environmentally friendly equipment. Mining companies are under pressure to reduce their carbon footprints, and equipment manufacturers that offer sustainable solutions will have a competitive advantage.

- Leverage Data and Digital Solutions: Offer data-driven services such as predictive maintenance and real-time monitoring to help clients improve their equipment management. These services can differentiate your company from competitors and add value for customers.

- Expand Rental and Leasing Services: Provide flexible rental and leasing options to meet the needs of smaller mining operations or companies with short-term equipment needs. This approach can open up new revenue streams and attract a wider range of customers.

Frequently Asked Questions (FAQs)

- What are the benefits of automation in mining equipment? Automation improves efficiency, reduces labor costs, and enhances safety by allowing equipment to operate autonomously in hazardous environments.

- Why is sustainability important in mining equipment manufacturing? Sustainability is crucial as mining companies face pressure to reduce their environmental impact. Energy-efficient and electric equipment can help reduce emissions and lower operating costs.

- How does data-driven technology benefit mining operations? Data-driven technology allows mining companies to monitor equipment performance in real-time, detect potential issues early, and optimize maintenance schedules, reducing downtime and improving efficiency.

- What are the advantages of renting mining equipment? Renting equipment provides flexibility, reduces capital investment, and allows mining companies to use the latest technology without long-term ownership commitments.

The mining equipment manufacturing industry in the USA is undergoing significant transformation as it adapts to new challenges and opportunities. From automation and sustainability to digitalization and electric machinery, manufacturers are at the forefront of innovation in the mining sector. Companies that embrace these trends, focus on customer needs, and invest in advanced technologies will be well-positioned for growth in the coming years.

As the global demand for minerals continues to rise, the future of mining equipment manufacturing looks promising. By staying ahead of technological advancements and industry trends, manufacturers can continue to play a pivotal role in shaping the future of mining while contributing to a more efficient, sustainable, and safe industry.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices