-

Email Us

- Top Reports

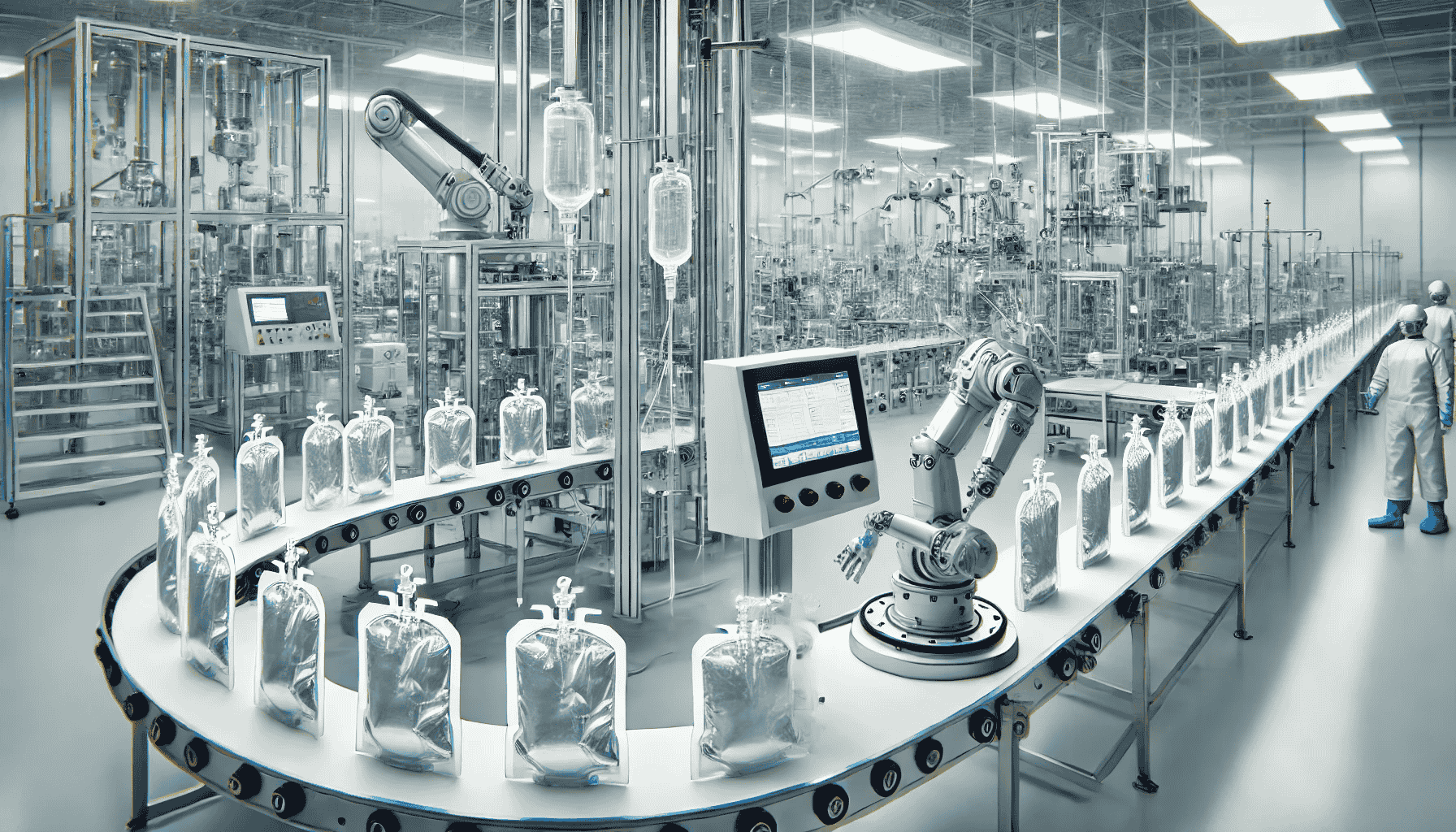

Top 10 Trends in IV Bags Manufacturing and Their Impact on the Healthcare Industry

Posted On 22 October, 2024

Introduction: IV (intravenous) therapy is a fundamental part of modern medical treatments, providing essential fluids, medications, and nutrients directly into the bloodstream. IV bags, being the critical carriers of these solutions, play a pivotal role in patient care. The demand for IV bags continues to grow, driven by increasing healthcare needs, advancements in medical technology, and a focus on improving patient outcomes. This blog explores the top 10 trends in IV bags manufacturing, providing insights into the current state of the industry and how these trends are shaping the future of healthcare.

Now Get Sample PDF Report on : IV Bags Market Growth Opportunities 2024-2031

https://www.statsndata.org/download-sample.php?id=365973

Top 10 Trends in IV Bags Manufacturing

1. Transition to Eco-friendly Materials A growing concern in the medical field is the environmental impact of disposable medical products. IV bags are typically made from plastic, which contributes to medical waste. Manufacturers are now focusing on eco-friendly alternatives, such as non-PVC (polyvinyl chloride) materials like polypropylene and polyethylene. These alternatives are not only more sustainable but also safer for patients, as they eliminate harmful chemicals such as DEHP (diethylhexyl phthalate), which is commonly found in PVC.

For instance, companies like Baxter and B. Braun are leading this shift by developing non-PVC IV bags that reduce environmental impact and are easier to dispose of. This trend aligns with the growing push for sustainability in healthcare, where reducing the carbon footprint is becoming a priority.

Actionable Tip: Manufacturers that prioritize eco-friendly materials can attract healthcare institutions that have sustainability goals. Offering recyclable and biodegradable IV bags can give companies a competitive edge in the market.

2. Rising Demand for Customizable IV Bags Healthcare providers are increasingly seeking IV bags that can be tailored to specific patient needs. Customization can include adjusting the volume, adding specific medications or electrolytes, or providing unique labeling to meet regulatory and hospital requirements. This trend is driven by the need for more personalized care and the ability to deliver treatments that cater to individual patients.

Manufacturers like Fresenius Kabi offer customizable IV bags that can be used for various therapies, including chemotherapy, nutritional support, and hydration. By providing flexibility in the design and formulation of IV bags, manufacturers can meet the growing demand for personalized healthcare solutions.

Actionable Tip: Offering customizable IV bags can help manufacturers tap into niche markets, such as specialized treatments or pediatric care. Customization also allows manufacturers to work closely with hospitals and healthcare providers to develop solutions that meet their specific needs.

3. Lightweight and Portable Designs for Home and Ambulatory Care With the rise of home healthcare and ambulatory care services, there is an increasing demand for lightweight and portable IV bags that are easy to transport and store. Traditional glass bottles and bulky containers are being replaced by flexible, compact IV bags that are more convenient for patients and caregivers.

Portable IV bags are ideal for home-based treatments, such as hydration therapy, antibiotic delivery, and chemotherapy. Companies like ICU Medical have developed innovative IV bags that are designed for use in home care settings, making it easier for patients to receive treatments outside of a hospital environment.

Actionable Tip: Manufacturers that focus on creating portable IV bags can cater to the growing home healthcare market. Offering products that are easy to use and transport can improve patient compliance and outcomes, while also appealing to healthcare providers looking for efficient solutions.

4. Smart IV Bags with Integrated Monitoring Systems The integration of technology into IV bags is one of the most exciting trends in the industry. Smart IV bags equipped with sensors and monitoring systems can provide real-time data on fluid levels, infusion rates, and patient responses. This data can be transmitted to healthcare providers, allowing for better monitoring and management of IV therapy.

Companies like Baxter are pioneering the development of smart IV bags that can be connected to hospital information systems, enabling seamless communication between devices and healthcare professionals. These advancements improve patient safety by allowing for early detection of issues such as incorrect dosages or blockages in the IV line.

Actionable Tip: Investing in smart IV bags and integrating them with digital healthcare systems can enhance the value of a manufacturer’s products. Offering real-time monitoring capabilities can appeal to hospitals and clinics that are focused on improving patient safety and reducing the risk of medical errors.

5. Focus on Sterility and Infection Control Infection control is a critical concern in healthcare, especially when it comes to IV therapy. Contaminated IV bags or improper handling can lead to serious infections, which is why manufacturers are placing a strong emphasis on sterile packaging and production processes. Advances in sterilization technologies, such as gamma irradiation and ethylene oxide sterilization, are ensuring that IV bags remain free of contaminants throughout the supply chain.

B. Braun, for example, has developed innovative packaging solutions that ensure sterility while simplifying the handling process for healthcare providers. This helps reduce the risk of contamination during the administration of IV therapy.

Actionable Tip: By investing in advanced sterilization techniques and maintaining high standards of infection control, manufacturers can build trust with healthcare providers. Sterile packaging that reduces the risk of infections can be a major selling point in the highly regulated healthcare industry.

6. Expansion of IV Bags in Emerging Markets The demand for IV therapy is rising in emerging markets, where access to healthcare is improving. As healthcare infrastructure develops in regions such as Asia, Africa, and Latin America, the need for IV bags is increasing, particularly in the treatment of chronic diseases, dehydration, and malnutrition.

Manufacturers like Fresenius Kabi are expanding their production capacity and distribution networks to meet the growing demand in these regions. By investing in local manufacturing facilities and forming partnerships with regional healthcare providers, manufacturers can ensure a steady supply of IV bags to meet the needs of these growing markets.

Actionable Tip: Manufacturers looking to expand into emerging markets should focus on building strong distribution networks and forming partnerships with local healthcare providers. Understanding the specific healthcare needs of each region can help manufacturers tailor their products to meet local demand.

7. Use of 3D Printing for Prototyping and Customization 3D printing is becoming a valuable tool in the development of IV bags, allowing manufacturers to quickly create prototypes and test new designs. This technology enables faster product development and customization, helping manufacturers meet the specific needs of healthcare providers and patients.

3D printing can also be used to experiment with new materials and features, such as flexible bags with built-in sensors or personalized designs for specific treatments. This reduces the time and cost associated with traditional manufacturing methods and allows for greater innovation.

Actionable Tip: Manufacturers that invest in 3D printing technology can accelerate their product development processes and offer more customized solutions. This can be particularly beneficial for creating specialized IV bags for niche markets, such as pediatric or geriatric care.

8. Increasing Regulatory Standards and Compliance The production of IV bags is highly regulated to ensure the safety and efficacy of the products. Manufacturers must comply with stringent guidelines set by regulatory bodies such as the FDA, EMA, and other international health organizations. As healthcare standards evolve, so do the regulations governing the production of IV bags.

Manufacturers are investing in quality control processes and technology to ensure that their products meet these regulatory standards. This includes testing for sterility, leak resistance, and biocompatibility, as well as adhering to Good Manufacturing Practices (GMP).

Actionable Tip: Staying compliant with regulatory standards is essential for maintaining credibility in the market. Manufacturers should invest in robust quality control systems and stay updated on regulatory changes to ensure their products meet the latest safety and efficacy requirements.

9. Reduction of Medical Waste through Recyclable Materials The healthcare industry generates significant amounts of waste, and IV bags contribute to this issue due to their disposable nature. Manufacturers are focusing on reducing the environmental impact of IV bags by developing recyclable materials and exploring ways to minimize waste during production and disposal.

Some manufacturers are working on IV bags that are made from biodegradable or recyclable materials, helping to reduce the environmental burden of medical waste. This aligns with the broader push for sustainability in healthcare, where reducing plastic waste is becoming a key goal.

Actionable Tip: By offering recyclable or biodegradable IV bags, manufacturers can appeal to healthcare providers that prioritize sustainability. Highlighting the environmental benefits of these products can help manufacturers build strong relationships with hospitals and clinics that are committed to reducing their carbon footprint.

10. Collaboration with Healthcare Providers for Innovation Collaboration between IV bags manufacturers and healthcare providers is becoming more common, as both parties work together to develop products that meet the specific needs of patients and clinicians. By engaging directly with hospitals, clinics, and healthcare professionals, manufacturers can gain valuable insights into the challenges and preferences of end users.

For example, some manufacturers are working with healthcare providers to develop IV bags that are easier to handle and reduce the risk of errors during administration. Others are focusing on creating IV bags with built-in safety features that prevent accidental spills or leaks.

Actionable Tip: Manufacturers that foster strong relationships with healthcare providers can develop more user-friendly products that meet the real-world needs of clinicians and patients. Collaborating with end users can lead to innovation and product improvements that enhance patient care and safety.

Questions Section

- What are the benefits of using non-PVC materials in IV bags? Non-PVC materials such as polypropylene and polyethylene are more environmentally friendly and eliminate harmful chemicals like DEHP, making them safer for patients and reducing the environmental impact of medical waste.

- How do smart IV bags improve patient care? Smart IV bags are equipped with sensors that provide real-time monitoring of fluid levels, infusion rates, and patient responses. This data helps healthcare providers make informed decisions, improving patient outcomes and reducing the risk of medical errors.

- Why is customization important for IV bags? Customizable IV bags allow healthcare providers to tailor treatments to the specific needs of patients, improving the effectiveness of therapies and reducing waste by offering the exact volume and additives required for each patient.

- How can 3D printing benefit IV bags manufacturers?

3D printing enables manufacturers to quickly create prototypes and test new designs, speeding up the product development process. It also allows for greater customization of IV bags, making it easier to create solutions that meet the unique needs of healthcare providers.

Conclusion: The IV bags manufacturing industry is evolving rapidly, driven by advancements in technology, sustainability efforts, and the growing demand for personalized care. Manufacturers are embracing trends such as eco-friendly materials, smart technology, and customization to meet the changing needs of healthcare providers and patients. By focusing on innovation, sustainability, and collaboration, IV bags manufacturers are playing a crucial role in improving patient care and shaping the future of healthcare.

As the healthcare landscape continues to evolve, manufacturers that prioritize these trends will be well-positioned to succeed in a competitive and dynamic market. By offering solutions that enhance patient safety, reduce environmental impact, and improve the efficiency of treatments, IV bags manufacturers can make a lasting impact on the healthcare industry.

Recent Blogs

Global Fitness Apps Market: Pioneering the Future of Health and Wellness Through Technology

Global Doll Ningyo Market: Reviving Heritage and Craftsmanship Through Modern Innovation

Global Basketball Training Equipment Market: Shaping the Future of Athletic Excellence with Adv

Global Women’s Sportswear Market: Driving Innovation and Sustainability in Activewear

Top 10 Trends in Chocolate Consumption by State: Insights, Impacts, and Strategies

Top 10 Trends in Mega Data Centers Driving the Future of Technology

Top 10 Trends in Waste-to-Energy Companies in the USA

The Ultimate Guide to High-Flow Nasal Cannula Brands: Trends, Insights, and Best Practices